Presentation GD

-

Upload

gaurav-majumdar -

Category

Documents

-

view

226 -

download

0

Transcript of Presentation GD

-

8/6/2019 Presentation GD

1/31

Procurement strategy group decision

making of an organization

P. S. Chakraborty

Adult, Continuing Education & Extension Department, Jadavpur University,

S. Ghosh

Mechanical Engineering Department, Jadavpur University,

G. Majumdar

Mechanical Engineering Department, Jadavpur University,

-

8/6/2019 Presentation GD

2/31

Decision taken by a group is always better than

individual decisions as group talent is more than that

of any individual.

Maximum cases of group decision making

processes are dominated by Yes-No voting system,

which may not reflect the decision makers realintention.

This paper deals with a case study of procurement

strategy decision making process for a manufacturingorganization with the help of Analytic hierarchy

process based group decision making model

considering preference intensity of individual voters.

-

8/6/2019 Presentation GD

3/31

The final decision is taken based on the ratio of

benefit from particular criteria to cost andassociated risk involved on that particular

criterion.

At the end it is also shown that this model maynot be feasible in dealing with the issues having

interdependencies i.e. when it is must to choose

one of the issues.

-

8/6/2019 Presentation GD

4/31

Introduction:

Timely strategic decision makings are having long

time implication on the organization performance

and must be taken considering their future impact on

business and the relationship with existing partners.

In this fast changing business scenario it is not

possible for any individual to have knowledge on

every aspects of business.

-

8/6/2019 Presentation GD

5/31

In maximum number of cases, group decisions are

made based on Yes-No voting system, which

indirectly influences few participants to side with the

majority.

In some cases few participants can not make up

mind, as they like both the issues up to certain

extent justifying the importance of preferenceintensity while decision making.

-

8/6/2019 Presentation GD

6/31

For example a participant may like an issue 65%,

but may not like by 35%. In that case under

traditional Yes-No voting system he would vote for

No, which does not reflect the real desire or

intention of the voters or participants.

Saaty and Shang (2007) proposed a conceptual

framework based on AHP to tackle social decision

making. They discussed the deficiencies oftraditional Yes-No voting system, where intensity of

preference of individual voters are not taken into

account.

-

8/6/2019 Presentation GD

7/31

If preference intensity or real desire of individual

voter is taken care, then the result may differ from

traditional system.

The idea expounded and propounded in the above

paper is mostly extended for a manufacturingorganizations procurement strategy group decision

making.

It is also found that this model may not be feasible

when there is interdependency between the issues

i.e. when one of the issues must be chosen.

-

8/6/2019 Presentation GD

8/31

Methodology :

oAt first step issues are assessed under benefit,cost and risk hierarchy.

o In the second step each issue is divided into two

alternatives as to do it or not to do it under the

benefit, cost and risk hierarchies.

o In the third step ratio of benefit to cost multiply

risk are calculated for to do it or not to do it

alternatives of all the issues.

o These alternatives address the intensity of

preference for the decision maker.

-

8/6/2019 Presentation GD

9/31

o These ratios assess the expected benefit and

associated cost and risk involved for the issues.

o In the fourth step for each issue, among the two

alternatives to do it or not to do it, which ratio

scores maximum in the third step is the fate for

that issue.

o Detail methodology is available at Saaty and

Shang 2007. Steps are compiled as follows:

Step 1- Compute the weightage of each criterionunder all the hierarchies.

Under each criterion compute the relative

importance of each issue.

-

8/6/2019 Presentation GD

10/31

Step 2-

Divide each issue into two alternatives.

Compute the relative importance of each alternative.

Step 3-

Calculate the benefit / cost x risk ratio.

Step 4-Decision based on the above Ratio

-

8/6/2019 Presentation GD

11/31

Case study:

This case is the problem of long term strategic

decision making process of an organization. In

this case benefit for particular criteria to cost

involved and associated risk are calculated.

All the departmental heads of the organization

were asked to take part in this decision making

process.

Under each hierarchy various criteria areconsidered. Under benefit hierarchy various

criteria considered are decrease employee

number, social obligation fulfillment and

-

8/6/2019 Presentation GD

12/31

Under cost hierarchy various criteria considered

are productivity cost, capital cost and opportunity

cost.

Under risk hierarchy various criteria considered

are future competitiveness, product damage and

long lead-time.

This model was used to solve the problem faced

by an automobile manufacturer to procure critical

component for the assembly. Various issues considered for this analysis are

produce at own plant, develop ancillaries and

procure from reputed manufacturer.

-

8/6/2019 Presentation GD

13/31

These issues are considered under benefit, cost

and risk hierarchies. In AHP pairwise comparison the priority value is

given in a scale of 1 to 9 by asking some simple

questions. One typical question may be To

decrease the number of employee, how much

important produce at own plant is when compared

to develop ancillaries?.

The AHP weightage in all the cases are thegeometric mean of the decision makers, as it was

difficult to arrive at a consensus weight.

-

8/6/2019 Presentation GD

14/31

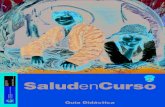

Table 1 shows procedure for generating priority

for benefit hierarchy using AHP.

Under benefit hierarchy these criteria weights are

written just below the criteria.

Priority weights were determined from pairwise

comparison. Relative importance of Produce atown plant is calculated as

(0.4 x 0.2) + (0.1x 0.45) + (0.5x0.6) = 0.425.

Table 2 shows various issues and criteria undercost hierarchy.

Similarly in table 3 various issues and criteria

under risk hierarchy are shown.

-

8/6/2019 Presentation GD

15/31

Benefit

Decrease

Employee

number

0.40

Social

obligation

fulfillment

0.10

Competitive

infrastructur

es

0.50Importance

0.20

0.30

0.50

0.45

0.35

0.20

0.60

0.30

0.10

0.425

0.305

0.270

Table 1: Weightage under benefit hierarchy

Produce at own

plant

Develop ancillaries

Procure from

reputed

manufacturers

-

8/6/2019 Presentation GD

16/31

Cost

Productivity

cost

0.40

Capital

cost

0.45

Opportunity

cost

0.15 Importance

0.35

0.30

0.35

0.60

0.30

0.10

0.45

0.30

0.25

0.478

0.300

0.223

Table 2: Weightage under cost hierarchy

Produce at own plant

Develop ancillaries

Procure from reputed

manufacturers

-

8/6/2019 Presentation GD

17/31

Risk

Future

Competitivenes

s

0.3

Product

damage

0.3

Long

lead-time

0.4

Importance

0.5

0.4

0.1

0.1

0.3

0.6

0.1

0.3

0.6

0.220

0.330

0.450

Table 3: Weightage under risk hierarchy

Produce at own

plant

Develop ancillaries

Procure from

reputed

manufacturers

-

8/6/2019 Presentation GD

18/31

Benefit

Decrease

Employee number0.4

Social obligation

fulfillment0.1

Competitive

infrastructures0.5

Produce at own plant

Do not produce at

own plant

Develop ancillaries

Do not develop

ancillaries

Procure from reputed

manufacturers

Do not procure from

reputed

manufacturers

Local

rating

0.9

0.1

0.75

0.25

0.9

0.1

Table 4: Overall rating under benefit hierarchy

Local Global Local Global GlobalLocalOverall

rating

0.18

0.02

0.225

0.075

0.45

0.05

0.75

0.25

0.6

0.4

0.8

0.2

0.3375

0.1125

0.21

0.14

0.16

0.04

0.9

0.1

0.6

0.4

0.75

0.25

0.54

0.06

0.18

0.12

0.075

0.025

1.825

0.575

1.510

0.890

1.755

0.645

0.884

0.461

0.736

0.549

0.904

0.467

-

8/6/2019 Presentation GD

19/31

Cost

Productivity

cost0.40

Capital cost

0.45

Opportunity

cost0.15

Local

rating

0.9

0.1

0.75

0.25

0.75

0.25

Table 5: Overall rating under cost hierarchy

Local Global Local Global GlobalLocalOverall

rating

0.315

0.035

0.225

0.075

0.2625

0.0875

0.8

0.2

0.7

0.3

0.8

0.2

0.48

0.12

0.21

0.09

0.08

0.02

0.8

0.2

0.6

0.4

0.6

0.4

0.36

0.09

0.18

0.12

0.15

0.10

1.780

0.620

1.555

0.845

1.600

0.800

0.985

0.530

0.747

0.534

0.721

0.512

Produce at own plant

Do not produce at ownplant

Develop ancillaries

Do not develop

ancillaries

Procure from reputed

manufacturers

Do not procure from

reputed manufacturers

-

8/6/2019 Presentation GD

20/31

Overall

rating

Risk

Future

competitiveness

0.3

Product

damage

0.3

Long

lead-time

0.4

Local

rating

0.8

0.2

0.75

0.25

0.6

0.4

Table 6: Overall rating under risk hierarchy

Local Global Local Global GlobalLocal

0.40

0.10

0.30

0.10

0.06

0.04

0.75

0.25

0.75

0.25

0.60

0.40

0.075

0.025

0.225

0.075

0.36

0.24

0.80

0.20

0.70

0.30

0.70

0.30

0.08

0.02

0.21

0.09

0.42

0.18

1.645

0.655

1.555

0.745

1.360

0.940

0.755

0.416

0.752

0.459

0.636

0.484

Produce at own plant

Do not produce at own

plant

Develop ancillaries

Do not develop ancillaries

Procure from reputed

manufacturers

Do not procure from

reputed manufacturers

-

8/6/2019 Presentation GD

21/31

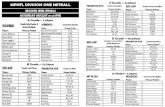

Ratio of Benefit / (Cost x Risk) for alternatives

Decision (to do or not to do)

Produce at own plant = 0.884 / (0.985 x 0.755)

= 1.19

Do not produce at own plant = 0.461 / (0.503 x 0.416) No

= 2.21

Develop ancillaries = 0.736 / (0.747 x 0.752)= 1.31

Do not develop ancillaries = 0.549 / (0.534 x 0.459) No

= 2.24

Procure from reputed manufacturers = 0.904 / (0.721 x 0.636)

= 1.97Do not procure from reputed = 0.467 / (0.512 x 0.484) Yes

Manufacturers = 1.88

Table 7: Decision on issues based on ratio

-

8/6/2019 Presentation GD

22/31

Result:

Table 7 shows the benefit / (cost x risk) ratio for

all the six alternatives. The benefit / (cost x risk)

ratios are the basis for choosing or rejecting the

particular issues.

In case of Produce at own plant alternative this

ratio is less than Do not produce at own plant

alternative.

Similarly in case of Develop ancillaries this ratio

is less than Do not develop ancillaries. Both these

issues will not be considered.

In case of Procure from reputed manufacturers

this ratio is more than Do not procure from

reputed manufacturer.

-

8/6/2019 Presentation GD

23/31

So this issue will be chosen as procurement

strategy of that particular critical compent.

Now if the criteria weightage under cost hierarchy

are changed as follows.

The productivity cost and opportunity cost

weightage are changed from 0.4 to 0.3 and 0.15 to0.25 respectively, keeping capital cost weighatge

constant.

Then again benefit / (cost x risk) ratio for all the six

alternatives are calculated, which is shown in table 8.

From table 8 it is clear that all the issues will be

rejected.

-

8/6/2019 Presentation GD

24/31

Ratio of Benefit / (Cost x Risk) for alternatives

Decision (to do or not to do)

Produce at own plant = 0.884 / (0.921 x 0.755)

= 1.27

Do not produce at own plant = 0.461 / (0.412 x 0.416) No

= 2.70

Develop ancillaries = 0.736 / (0.665 x 0.752)= 1.47

Do not develop ancillaries = 0.549 / (0.446 x 0.459) No

= 2.69

Procure from reputed manufacturers = 0.904 / (0.636 x 0.636)

= 2.23Do not procure from reputed = 0.467 / (0.422 x 0.484) No

Manufacturers = 2.29

Table 8: Decision on issues based on ratio after weightage modification

-

8/6/2019 Presentation GD

25/31

Conclusion:

In this case procurement strategy was chosen

considering the intensity of preference of individualparticipants, not as per traditional Yes-No voting

system. The objective as well as subjective judgment

considering multiple issues is taken care off using

AHP methodology. This model is suitable for any

other kind of decision making process, though people

may not yet be ready for such voting system, instead

traditional Yes-No voting system. It can also beconcluded that this model may not be proved feasible

in case of interdependence between the issues i.e.

when one of the issues must be chosen.

-

8/6/2019 Presentation GD

26/31

Acknowledgement:

This project has been funded by Jadavpur

University (Jadavpur University Research Grant-Ref. No. P1 / 1730/ 05 dated 28.10.2005)

References:

Bhattacharya A, Sarkar B, Mukherjee S K. A new methodfor plant location selection: a holistic approach.

International Journal of Industrial Engineering: Theory

Application and Practice 2004; 11; 330-338.

Chakraborty P S, Majumder G, Sarkar B. Performanceevaluation of existing vendors using Analytic Hierarchy

Process. Journal of Scientific and Industrial Research

2005; 64; 648-652.

-

8/6/2019 Presentation GD

27/31

3.Choudhury A K, Shankar R, Tiwari M K. Consensus-basedintelligent Group decision making model for the selction

of advance technology. Decision Support systems 2006;42; 1176-1799.

4.Fan Z P, Ma J, Jiang Y P, Sun Y H, Ma L. A Goalprogramming approach to Group decision making based

on multiplicative preference relations and fuzzy preference

relations. European Journal of Operational Research

2006; 174; 311-321.

5.Gerwin D. Manufacturing flexibility: a strategicperspective. Management Science 1993; 39; 395-410.

6.Ghodsypour S H, Obrien C. A decision support system forsupplier selection using an analytic hierarchy process andlinear programming. International Journal of Production

Economics 1998; 56-57; 199-222.

-

8/6/2019 Presentation GD

28/31

7.Hua Z S, Jiang W, Liang L. Adjusting inconsistencythrough learning in group decision making and its

application to Chinas MBA recruiting interviews. Socio-Economic Planning Sciences 2007; 41; 195-207.

8.Kraus S. Strategic Negotiations in Multi-agentEnvironments. Massachusetts Institute of Technology

Press: Cambridge; 2001; 17-29.

9.Lootsma F A, Schuijt H. The multiplicative AHP, Smart andElctre in a common context. Journal of Multi-Criteria

Decision Analysis 1997; 6.

10.Mirani R, Moore D, Weber J A. Emerging technologies

for enhancing supplier-reseller partnerships. IndustrialMarketing Management 2001; 30(2); 101-114.

11.Mich L, Gaio L, Fedrizzi M. On Fuzzy logic-basedconsensus in group decision, Procedings IFSA 1993; 698-

700.

-

8/6/2019 Presentation GD

29/31

12.Mikhalov L. Group prioritization in the AHP by fuzzypreference programming method. Computers and

Operations Research 2004; 31.13.Ragatz G L, Handfield R B Scannell T V. Success factors

for integrating suppliers into new product development,

Journal of Poduct Inovation Management 1997; 14; 190-

202.

14.Saaty T L. The Analytic Hierarchy Process. McGraw-Hill:New York; 1980.

15.Saaty T L, Shang J S. Group decision-making: Head-count versus intensity of preference. Socio-Economic

Planning Sciences 2007; 41; 22-37.16.Sarkar B, Choudhary J P, Mukherjee S K. Selection ofprofessionals using Analytic Hierarchy approach. Journal

of Institute of Engineers (India). Interdisciplinary Division

2000; 16-18.

-

8/6/2019 Presentation GD

30/31

17.Shih H S, Shyur H J, Lee E S. An extension of TOPSISfor Group decision making. Mathematical and Computer

Modelling 2007; 45; 801-813.18.Srdjevic B. Linking AHP and Social choice methods to

support group decision making in water management.

Decision Support System 2007; 42; 2261-2273.

19.Wanyama T, Far B H. A protocol for multi-agentnegotiation in a group-choice decision making process.

Journal of Network and Computer Applications 2007; 30;

1173-1195.

20.Weele A V. Purchasing and Supply Chain Management:

Analysis, Planning and Practice. Thomson Learning:London; 2000.

-

8/6/2019 Presentation GD

31/31