Soy protein isolate

-

Upload

karthik-senthil -

Category

Food

-

view

124 -

download

1

Transcript of Soy protein isolate

SOY PROTEIN ISOLATE

Soy Protein Isolate or Isolated Soy Protein(ISP) is the major proteinaceous fraction of soybeans prepared from dehulled,defatted soyflakes by removing the majority of non-protein components and must contain not less than 90% protein on a moisture-free basis.

Soy protein isolate is a complete protein as it contains all the essential amino acids.It has a neutral flavor and taste.

SOY PROTEIN ISOLATE

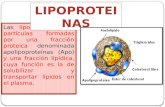

COMPONENT WEIGHT %

PROTEIN 90FAT 0.5ASH 4.5TOTAL CARB 0.3

Typical composition of ISP: (Moisture-free basis)

PRINCIPLE The basic principle of ISP production

is simple.SOLUBILIZATION:Using defatted soy flour or

flakes as the starting material, the protein is first solubilized in water and alkali.

SEPERATION:The solution is separated from the solid residue.

PRECIPITATION:Finally, the protein is precipitated from the solution, separated and dried.

PRODUCTION PROCESS

STEPS INVOVLED IN PRODUCTION

STARTING MATERIAL: Dehulled, defatted, edible

grade soy flakes or meal with the highest possible protein solubility index are used.

Although the rate of protein extraction from finely ground flour would be faster, flakes permit easier separation after extraction.

(1)Protein extraction: The flakes are mixed with the extraction medium in agitated, heated vessels. The extraction medium is water to which an alkali is added, so as to bring the pH to neutral to slightly alkaline reaction(7.5-9.0). Under these conditions, the majority of the proteins go into solution.

(2)Solid-liquid separation after extraction: The extract contains considerable amount of fine particles of extracted flour, the elimination of which, prior to precipitation, is necessary in order to obtain a "curd" of acceptable purity.

(3)Extract treatment: The clarified extract can be treated so as to remove certain impurities, thus improving the colour and nutritional quality and modifying the functional properties of the final product. The use of membrane processes for extract purification and concentration is industrially applied in Europe and Japan.

(4) Precipitation: The protein is precipitated from the extract by bringing the pH down to the isoelectric region(around 4.5). The type of acid used or the temperature of precipitation do not affect the yield or purity of precipitated protein.

(5)Separation and washing of the curd: The precipitated protein (curd) is separated

from the supernatant (whey) by filtration or centrifugation. Desludger or decanter centrifuges can be used for this purpose. The curd must be washed with water in order to remove residues of whey solubles.

(6)Drying: The usual method for drying the washed curd is

spray-drying and the fine powder is packaged.

a: Solubilization of the soy proteins in the salt solutions (salting-in) followed by precipitation by dilution with water.

b: Precipitation from the extract at near-boiling temperature, using calcium salts

c: Ultrafiltration of the extract so as to remove the low molecular weight components of the whey , leaving a concentrated solution of protein

d: Physical separation by floatation. e: Purification of the extract by ultrafiltration,

filtration through activated carbon and ion exchange, in order to increase curd purity.

ALTERNATIVE PROCESS

The product purity and yield depends on many different parameters like,

Alkalinity Extraction time Temperature Ratio of water to soy flakes Heat treatment Agitation

APPLICATIONS

Neutralised isolate :Mostly the isolate is neutralized (Na or K proteinates ) to make it more soluble and functional.

Uses: Meat and dairy products and varied applications requiring emulsification, emulsion stabilization, water and fat absorption, adhesive or fiber-forming properties etc.

Generally ISPs are used in,dairy-type products such as beverage

powders, infant formulas, liquid nutritional meals, and some varieties of liquid soymilk

bottled fruit drinkspower barssoups and saucesmeat analogs that resemble conventional

foods in color, texture and tastebreads and baked goodsbreakfast cerealsmany weight and muscle gain products in

the fitness market

SOY PROTEIN WHEY PROTEINSOURCE Soy bean Cow’s milkCOST Not as expensive as whey

protein.More expensive than soy protein.

COMPOSITION Mixture of globular proteins immobilized in defatted flakes of flour while allowing leaching off of soy whey proteins, salts and carbohydrates.

Mixture of globular proteins which have been isolated from whey, a byproduct of cheese production. It is a 5% lactose solution in water.

HEALTH BENEFITS Reduce cholesterol, symptoms of osteoporosis, hormonal diseases, heart disease and increase in thyroid metabolism.

Natural antibacterial and anti viral, maintaining weight, improves immune system functions and digestive system functions.

HARMUL EFFECTS Can cause digestive disorders if allergic to product.

Heat denatured whey can cause allergies.

MARKET AVAILABILITY Tofu, soy milk, food bars, burgers, soy flour, soy beans.

Infant formulas, nutrient special products

REFERENCESCogan U., A. Yaron, Z. Berk and S. Mizrahi (1967)Isolation of Soybean Protein: Effect of Processing Conditions on Yield and Purity. J. Am. Oil Chem. Soc. 44: 321Elias S. (1979)Food Eng. 51(10), 81Kolar C.W., S.H. Richert, C.D. Decker, F.H. Steinke and R.J. Van der Zanden (1985)Isolated Soy Protein in "New Protein Foods", A.M. Altschul and H.L. Wilke eds. Academic Press Inc. Orlando, Florida."Soy Protein Products" Soy Protein Council, Washington, D.C.Soya Bluebook (1990)Soyatech Inc. Bar Harbor, ME.