Presentacion de Prueba

description

Transcript of Presentacion de Prueba

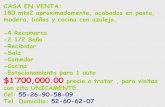

–®

10 REUNION LATINOAMERICANA DE LOGISTICA10 REUNION LATINOAMERICANA DE LOGISTICA

Desarrollo de Proveedores Desarrollo de Proveedores Logísticos:Logísticos:

Six Sigma y su aplicaciónSix Sigma y su aplicación

Luciano Pompei

18 al 20 de Noviembre de 2008Gramado, RS - Brasil

–®

OBJETIVOOBJETIVO

Brindar a la audiencia elementos que Brindar a la audiencia elementos que permitan permitan relacionar los conceptos de relacionar los conceptos de Six Sigma y Mejora Contínua con el Six Sigma y Mejora Contínua con el Desarrollo de Proveedores Desarrollo de Proveedores LogísticosLogísticos

–®

Pautas de la ConferenciaPautas de la Conferencia

General más que EspecíficaGeneral más que Específica

Respeta idioma original de la informaciónRespeta idioma original de la información

Enfoque desde posición de comprador de Servicios LogísticosEnfoque desde posición de comprador de Servicios Logísticos

Considera la naturaleza de la AudienciaConsidera la naturaleza de la Audiencia

–®

AgendaAgenda

• Acerca de Dow y Six Sigma en Dow

• Repaso de la metodología (Six Sigma MAIC process)

• Aplicación e impacto en el Desarrollo de Proveedores Logísticos

• Casos Ejemplo

–®

Dow Portfolios

New VenturesUnallocated and Other

Hydrocarbons and EnergyHydrocarbons & Energy

PolyethylenePolypropylenePolystyreneCore ChemicalsEthylene Oxide/Ethylene Glycol

BasicPlastic & Chemicals

Dow AgroSciencesAgricultural Sciences

Dow AutomotiveDow Building SolutionsDow EpoxyPolyurethanes and Polyurethane SystemsSpecialty Plastics and ElastomersTechnology Licensing and CatalystDesigned PolymersDow LatexSpecialty Chemicals

PerformancePlastics & Chemicals

–®

DOW LATIN AMERICA–Franco da Rocha

–Jundiaí

–Guarujá

–Pindamonhangaba

–Camaçari

–El Tablazo

–Tlaxcala

–Betaseal

– –Polyurethanes,–Polyols,

–Polyglycols,–Agrochemicals

–Polyurethanes,–Polyols ,

–Polystyrene,–Agrochemicals

–Zetabon–®

–Latex

–Polyurethanes–Systems &

–Agrochemicals

–Agrochemicals

–Ethylbenzene–Styrene

–Monomer,–and TDI

–Ethylene,–Polyethylene

–Polyetyhlene

–PP Compounds,–SAN and ABS

–resins and–nylon products

–Caustic, Propylene–Oxide, Propylene

–Glycol, Chlorinated–Solvents, Chlorine

–Aratu

–San– –Lorenzo

–Cartagena

–Talcahuano

–Polyurethans Systems,–food packaging and

–Headliners

–Polyols,–polyglycols

–Latex, Epoxy,–Derakane–®–,–Polystyrene

–Cubatão–Polyethylene

–Vinyl Acetate Monomer

–Cabo

–Seeds

–Tlalnepantla

–Bahia Blanca

–Jardinópolis

–Branco Dow-SP

–Colón–specialty seeds

–Pergamino–specialty seeds

–Venado Tuerto

–specialty seeds

–Compañía MEGA

–®

Six Sigma Brief History within DOW

– 1940’ Japanese companies, “all defects are preventable”

– 1987 Comes to EEUU with Motorola, known as “Six Sigma”

– 1998 DOW searchs an enabler to the next productivity level

– 1999 DOW launches a pilot– 2000 DOW starts full implementation

–®

Concept: Cost of Poor Quality (COPQ)

Traditional Quality CostsTangible

ScrapRework

InspectionWarranty

Rejects

Administration /DispositionConcessions

Lost OpportunityHidden Factory

Additional Costs of Poor QualityIntangible

Difficult or impossible to measure

Average COPQ Approximately 15% of Sales

More Setups Expediting Costs Lost Sales Late Delivery Lost Customer Loyalty Excess Inventory Long Cycle Times Engineering Change

Orders

–®

66

A B C D CustomerSupplier

A x B x C x D = A x B x C x D = 99.9997%99.9997%

99.9999% 99.99998% 99.9993% 99.99999%

CustomerA B C D

Return

Check Check Check Double Check

Waste

Waste

Delay

Rework

Rework

95% 99% 98% 97%

A x B x C x D = A x B x C x D = 89% 89%

Supplier

Waste

NOT 6NOT 6

Concept: The “Hidden” Factory

–®

% AccurateDefects per Million

Opportunities

2 308,50069.15 3 66,80093.32 44 6,2106,21099.38 99.38 55 23323399.97799.9776 3.499.9997

11 691,500691,500 30.8530.85

77 0.020.0200

99.99999899.999998

Concept: Defects per Millon Opportunities

–®

Target

6

USLLSL

6ExamplesExamples

Delivery Lead Time Delivery Lead Time Product AvailabilityProduct Availability

Payment TermPayment Term MOT CapacityMOT Capacity

Inventory LevelInventory Level

Concept: Distance from the process Mean

–®

M Measure (what’s the Y) DEFECT FOCUSED

A Analyze (what are the X) ROOT CAUSES

I Improve (how do we optimize X to get desired Y) SOLUTION PLAN

C Control (how do we control X to get desired Y) SUSTAINABILITY

How MAICMAIC Six Sigma Works: Y = f(X)

Effect Symptom Dependent

Cause Problem Independent

–®

Measure (MAIC)

Understand the Process and Potential Impact Understand the Process and Potential Impact

DefineProblem

DefineProblem

UnderstandProcess

UnderstandProcess

CollectData

CollectData

ProcessPerformance

ProcessPerformance

Baseline – New Sigma

Baseline – New Sigma

Estimated Financial Impact

Estimated Financial Impact

–®

What do you want to improve? What is your ‘Y’?

ReduceComplaints

(int./ext.)

ReduceCost

ReduceDefects

Problem Definitions need to be based onquantitative facts supported by analytical data.

Problem Definitions need to be based onquantitative facts supported by analytical data.

What are the Goals?

DefineProblem

DefineProblem

UnderstandProcess

UnderstandProcess

CollectData

CollectData

Measure (MAIC)

–®

To understand where you want to be, you need to know how to get there.

To understand where you want to be, you need to know how to get there.

Map the ProcessMap the Process

Measure the ProcessMeasure the Process

Identify the variables - ‘x’Identify the variables - ‘x’

Understand the Problem -’Y’ = function of variables -’x’

Y=f(x)

Understand the Problem -’Y’ = function of variables -’x’

Y=f(x)

DefineProblem

DefineProblem

UnderstandProcess

UnderstandProcess

CollectData

CollectData

Measure (MAIC)

–®

What do you need to know?What do you need to know?

Measurement System

Repeatability Reproducibility Timeliness Cost Accuracy Adequacy

Process Performance

Customer Satisfaction

Defects Rework Scrap Yield

Complaints Returns Service Level

What do you want to know?What do you want to know?

DefineProblem

DefineProblem

UnderstandProcess

UnderstandProcess

CollectData

CollectData

Measure (MAIC)

–®

Analyze (MAIC)

Data AnalysisData Analysis

Identify Critical Factors

Identify Critical Factors

How is Process Performing? What are Vital Process Elements?

How is Process Performing? What are Vital Process Elements?

Assess Current Process

Assess Current Process Brainstorm and Affinitize

Collect data to support hypothesis

Validate Root Causes with Knowledge and common sense or statistically

–®

Assess Project Goals

Current Process Performance

IdealProcess

Pro

ce

ss

Pe

rfo

rma

nc

e ()

Project Goal too passive

Project Goal too aggressive

Time

Realistic Project Goal

Assure Project Goals are Realistic and AchievableAssure Project Goals are Realistic and Achievable

Analyze (MAIC)

–®

Improve (MAIC)

DevelopImprovement

Plan

DevelopImprovement

Plan

Optimize KeyFactors

Optimize KeyFactors

Reduce Variation/Defects

Reduce Variation/Defects

Verify Impact

Verify Impact

Goals Benefits Timelines Resources Roles Responsibilities

DOE Process Limits

Implement Improvements

Control Vital X’s

Capability Analysis

Regression Hypothesis

Testing Assess against

Project Goal

Implement & Validate ImprovementsImplement & Validate Improvements

–®

Control (MAIC)

Implement Control Plan

Implement Control Plan

Leverage toother Processes

Leverage toother Processes

Document &Standardize

Document &Standardize

SPC FMEA Process Capability Update Control

Plan

Similar Processes Like Products

Procedures & Work Instructions

Update Systems

Assure Controls in Place to Maintain Improvements Look for Leverage Opportunities

Assure Controls in Place to Maintain Improvements Look for Leverage Opportunities

–®

Process Control

100500

80

70

60

50

40

30

20

10

0

-10

Observation Number

Individual Value

I Chart for C5 by C6

1

X=16.12

3.0SL=31.84

-3.0SL=0.3996

2

Before After

Develop effective mechanisms to maintain control of process improvements

Apply controls to process inputs - Xs (not necessarily output - Y)

Apply controls to process inputs - Xs (not necessarily output - Y)

SPCSPC

Control (MAIC)

–®

Control PlanUpdate process control plan to maintain improvements

Now we Understand the Problem / Defect Statement

Y = f ( x1*, x2, x3, x4

*, x5, X6)

Process(Parameters)

X4 *

Output (Y)

X3

X2

X6X5

X1*

Vital Factors included in Process Control PlanVital Factors included in Process Control Plan

Control (MAIC)

–®

Control PlanUpdate process control plan to maintain improvements

Now we Understand the Problem / Defect Statement

Y = f ( x1*, x2, x3, x4

*, x5, X6)

Process(Parameters)

X4 *

Output (Y)

X3

X2

X6X5

X1*

Vital Factors included in Process Control PlanVital Factors included in Process Control Plan

Control (MAIC)

–®

Six Sigma Tools & Modules Fundamental Quality Tools

• Pareto Analysis

• Process Mapping

• Brainstorming

• Cause-and- Effect

Process Characterization• Defectives

• Defects

• Variables Data

Capability Analysis Measurement System Evaluation Design of Experiments

Statistical Process Control (SPC) Hypothesis Testing

• t Test

• Analysis of Variance (ANOVA)

• Homogeneity of Variance (HOV)

• Chi Squared (2)

Linear Regression Failure Mode and Effects Analysis (FMEA) Short and Long Term Analysis Power & Sample Size

–®

Six Sigma Summary4 Step Methodology for Process Improvement

MeasureMeasureCharacterize Process

Understand CausesAnalyzeAnalyze

Improve and Verify ProcessImproveImprove

Maintain New ProcessControlControl

–®

Company Continuous Improvement Philosophy

Six Sigma

Supply Chain

Projects

OutsourcingsWarehouse

ConsolidationNew MOTs

From Six Sigma to Logistic Services Providers

New Routes New Services Others

Opportunity for Logistics Services ProvidersDevelopment…..Relationship…..Business

Manufact. Projects

Commercial

Projects

R&D

Projects

Purchasing

Projects

–®

LSP Development…Relationship…Business

Needs• Agreement on non negotiable EH&S and Customer

Satisfaction indicators• Identify Key Process Variables and associated limits

(upper/lower)• Identify Defects and validate them (both parties)• Link Variables from Required Services to Variables from

Offered Services• Define frame for continuous improvement and mutual

benefits

Required Services(in/out source

strategy)

Offered Services(comm/mktg

strategy) Expense (costs)Income (gains)

Customer Satisfaction (ours)EH&S

WELSP/3PL

Six Sigma is a useful Enabler to set the Basis

–®

•Good Hot Coffee•Fast Line, Especially for

Refills•Close to Telephones•Room to Chat•Close to High-Capacity

Restrooms

Customer PerspectiveCustomer Perspective(Conference Attendees)(Conference Attendees)

30

Focusing On Customers

Supplier PerspectiveSupplier Perspective(Hotel)(Hotel)

•Good Hot Coffee•Clean China•Clean Linen•Attractive Display•Extras - Snacks

What Makes a Good Coffee Service?

LSP Development…Relationship…Business

–®

BUENOS AIRES

Veamos algunos casos que derivan en desarrollo de Proveedores Logísticos

–®

BUENOS AIRES

Agreement

If one truck does at least 3 trips in the day, then there is a 20% of discount on the agreed freight rate

CASE I: Productivity Agreement with LSP

Ext. WH3PL1 Owned

My Site

Warehouse

Plants

Shipments in/out Ext. WH / 3PL1

–®

Ext. Wh.1RM1

RM2

RM9

RM7

RM6

RM8

Ext. Wh2

RM5

RM4Warehouse

RAWMATERIALS

RM3

Ext. Wh.3

ProductionFacilities

WarehouseFINISHED GOODS

Ext. Wh.4

My SITEExt. Wh.

Customers

Customers

Ext. Wh.

Ext. Wh.

Ext. Wh.

Customers

RAW MATERIALS FINISHED GOODS

Ext. Wh

Ext. Wh.

Ext. Wh.

Customers

Ext. Wh.

CASE II: Redesign / Outsourcing

–®

What does it mean?What does it mean?

Outsourcing / 3PL as strategic partner

New Integrated Warehouse building / MP1 Supplier Operation, both “in site”

Long term contracts development, My land usage should be taken into account

A BETTER AND SIMPLER SUPPLY CHAIN

RM1

RM2

RM9

RM7

RM6

RM8

RM5

RM4

WarehouseRAW

MATERIALS

RM3

ProductionFacilities

WarehouseFINISHED GOODS

My SITE

Ext. Wh.

Customers

Customers

Ext. Wh.

Ext. Wh.

Ext. Wh.

Customers

RAW MATERIALS FINISHED GOODS

Ext. Wh.

Ext. Wh.

Ext. Wh.

Customers

Ext. Wh.

CASE II: Redesign / Outsourcing (cont.)

–®

Ext. WH3PL1 Owned

My Site

Warehouse

Plants

My CUSTOMERHead Office andMain Warehouse

Ex. WH3PL2 Owned

CUSTOMER’sCUSTOMER

Ext. WH2

Ext. WH1

BUENOS AIRES

Changes / Improvements

My 3PL1 was incorporated as My Customer’s 3PL / shared WH. System complexity was reduced as long as inventory was properly

concentrated and delivering / shipping points were decreased Probability of non optimum movements (extra cost) is lower New Design brings benefits for My Customer, 3PL1 and Me It is True, there are losers: Owners of My Customer’sExt. WH.

CASE III: Integration with Customers

This Synergy between My Cusotmer and Me would result in a supply chain model aligned to our

strategy, which promotes a better service level and also cost advantages at both sides

–®

LEVEL OF INTEGRATION & COMPLEXITY

- Leverage in/out supplier-rates without changing current supply chain

- Develop new logistic alternatives (vessel, bimodal, new port, etc.)

- Design a tailor made sc work process involving resources of both Companies

- Involve a 3PL (Operador Logístico) to be accountable for most of supply chain

- Involve a 3PL (Operador Logístico) to be accountable for the whole supply chain

- Others

CASE III: Integration with Customers (cont.)

–®

CONCLUSIONES Six Sigma es una alternativa de aplicación de cultura de mejora

contínua, comprende el uso de herramientas y técnicas (estadística, liderazgo de proyectos, resolución de conflictos)

La aplicación de Six Sigma es un disparador de oportunidades de desarrollo de Proveedores Logísticos (outsourcing, integración, sinergía, productividad, nuevos servicios, etc.)

El Costo no se plantea primariamente como un Defecto sino como consecuencia de un Defecto relacionado a una variable clave de proceso

Es fundamental la identificación temprana de conflictos de intereses (defectos/ expenses, servicios/ gains). Recordar ejemplo de tasa de café.

Se busca el mejoramiento del sistema (visión holística)

Hay ganadores y perdedores como consecuencia del mejoramiento del sistema

–®

MUITO OBRIGADO! MUCHAS GRACIAS!

MANY THANKS!