LADE-/ ERNTE-/ SILOPROFI - poettinger.at2 Professionals achiev LADEPROFI/ ERN It is harvest time –...

Transcript of LADE-/ ERNTE-/ SILOPROFI - poettinger.at2 Professionals achiev LADEPROFI/ ERN It is harvest time –...

-

Self-loading, short cutting forage wagons

LADE-/ ERNTE-/ SILOPROFI

Lade_Ernte_Silo_engl 23.06.2003 9:12 Uhr Seite 1

-

2

Professionals achievLADEPROFI / ERNIt is harvest time – time to bring in the forage –

maintaining quality and eliminating bottlenecks.

The PROFI range of silage trailers is reliable, loads the

forage in record time with 6 or 8 feeding tine bars,

protecting the crop as it is loaded.

The Pöttinger PROFI range guarantees tidy pickup,

excellent chop length consistency and the highest

degree of operating comfort.

That is what impresses every specialist.

The self-loading wagon is still the most economic form

of crop handling for any size of operation. That is why

farmers who want to cut costs consider this system the

only option.

Lade_Ernte_Silo_engl 23.06.2003 9:12 Uhr Seite 2

-

3

hieve moreERNTEPROFI / SILOPROFI

The one-man harvestpage 14 to 15

Silage making in record timepage 16 to 19

Axles and tyrespage 20 to 21

Technical datapage 22 to 23

Pickup detailspage 4 to 5

Profimatic – loading systempage 6 to 7

Profimatic – cutting systempage 8 to 11

Profi – loading conveniencepage 12 to 13

Lade_Ernte_Silo_engl 23.06.2003 9:12 Uhr Seite 3

-

4

The PROFI pick-up leaves nothinA PROFI picks up the croptidily and fills the wagon

right into every corner.

The high-performance

pickup with 5 or 6 rows of

tines is the frontline for

achieving the enormous

loading capacity at high

speed.

● Five rows of tines on LADE/ERNTEPROFIs and 1.65 m wide pickup ● The speed of the tine movements is synchronised with the speed of the

loading system● The closely spaced tine sequence ensures that the crop is lifted cleanly

even at high loading speeds.● The tines are bolted onto gauge tubes. Heavy-duty Super "C”-quality tines

have a longer service life. The tubes are supported in the middle by asupport disc, right where the stress is highest.

● The height-adjustable rubber wheels contact the ground on exactly thesame line as the tines and guide the pickup perfectly through each hollow.

● The pickup transmission with integrated clutch disengages automaticallywhen the pickup is raised.

● A height-adjustable pickup guide plate ensures that even really short fora-ge is not left behind.

● The fine-tuned countersprings absorb shocks and prevent the pickup fromsinking in on damp ground.

Pickup cam rollersTwin-race deep grooveball bearings for heavy-duty applications.

Big on details:

Profimatic

Lade_Ernte_Silo_engl 23.06.2003 9:12 Uhr Seite 4

-

Between the pickup and the loadingsystem the crop passes over heat-treated transfer plates. Foreign objectsand earth are able to fall through awayfrom the crop here.This system is only available fromPöttinger. The knives are fully protected.

5

othing behind

The hardened steel camtrack has a solid centre.Not a casting – thismaterial does not weareven after years ofservice.

Tine controlAt the point the tinescontact the ground theyare swept back to avoiddamage to the sward: dirtdoes not get flung up andthe tines are subject tolower wear.

Pick up

SILOPROFI: even higher capacitySix rows of pickup tines and a pickup width of 1.80 m with a special suspensionsystem featuring a rigid frame and optimum freedom of movement.● Two hinged support links at either end provide perfect ground hugging. Nothing

is left behind: the sward remains undamaged and no dirt is picked up.● Trailing jockey wheels on SILOPROFI models enable the wagon to

corner more easily without damaging the ground.● The pick-up tines are bolted on tubes. These tubes are supported

centrally by a support disc, right where the stress is highest.

Side inspection portfor quick check of rollersand cam track.

Lade_Ernte_Silo_engl 23.06.2003 9:12 Uhr Seite 5

-

The smooth operator:years ahead on

experience● Offset feeding tines with a cam track control

system at each end saves power during loading.● Pickup, chopping and loading in quick succession – no

peak loads on any of the knives.● Due to the optimum cam control system, the forage is picked up

tidily and cut effortlessly at two banks of knives. The virtually circular camtrack controls the feeding tines to guarantee jolt-free loading even when thewagon is full – good for the wagon, forage and driver.

● Due to the pickup bearings being located nearer the centre there is lessbending stress acting on the shaft than on single-piece systems.

● Stress on each cam control track is 50 % lower than systems with asingle cam track.

● Feeding tine shaft has hardened and polished end stubs for a longerservice life.

6

You couldn’t ask for hiProfimatic

"We harvest around 160

hectares a year and need to

be able to rely on a high-

performance machine. We

were impressed with the

loading performance and

the consistency of the

chop."

Diermayr Günter andGrimmer Klaus(Owners of anERNTEPROFI 3)

Lade_Ernte_Silo_engl 23.06.2003 9:12 Uhr Seite 6

-

It's the details that really matter:

Cutting system crankcan also be used torotate the loadingsystem. The feedingtines can be rotatedmanually. Makeslubrication and mainten-ance much easier.

SILOPROFI with auto-matic chain lubricationThe chain drives for theloading system andpickup are lubricatedautomatically. Even onreally gruelling days thetransmission always hasthe correct amount ofoil.

Wide angle c.v. jointp.t.o shaft with cam-type clutch as standardThe clutch disengagesautomatically if it isoverloaded. The clutchengages again auto-matically after the p.t.o.shaft speed has beenlowered.No grating – trans-mission componentscannot be overloaded.

7

Bolted pickup shaftbearings with repla-ceable bushes. Easy to remove,individually replace-able, extremely wearresistant.

Profimaticor higher loading performance

Central lubricationmanifoldThe pickup bearingsare lubricated from acentral point asstandard.

LADEPROFI and ERNTEPROFI have six feeding tine bars, and SILOPROFI haveeight feeding tine bars for an extremely rapid loading sequence. These wagonsare known for their smooth operation and above average capacity.The crop is handled carefully and cut precisely, without power peaks.

Lade_Ernte_Silo_engl 23.06.2003 9:13 Uhr Seite 7

-

8

... the best knife security on This is the best knifesecurity on any self-loading

wagon: If an object triggers

the security system, there is

only minimal resistance as

the knife moves back (up to

13 cm clearance), and then

clicks into place again.

Non-stop loading without

leaving the cab.

The original with serrated blade● Knives of hardened tool steel, serrated on one side,

guarantee a long service life.● Their perfect serrated blade ensures that even

after the edge has dulled a good cut is stillachieved.

● The curved knife shape delivers acontinuous, power-saving cut.

● The forage is always cut with precision, itis not dragged through, torn apart orsquashed. The knives are just hookedinto the holders so they can easilybe removed individually. Thismakes maintenance easier.

T●

●

●

Profimatic

Lade_Ernte_Silo_engl 23.06.2003 9:13 Uhr Seite 8

-

9

y on any self-loading wagon

The knife security system● Patented knife security – technology that has been proven over a thousand

times.● Each individual knife is protected. Triggering pressure remains the same,

regardless of where the foreign object makes contact. The knife moves awaywith hardly any resistance after the triggering pressure has been reached.This protects both the knife and its edge. The knife mounting absorbs theimpact from the foreign object, during which the knife acts against a springto move slightly in the direction of rotation of the rotor. If the knife moves farenough the trigger roll presses it out of its holder. The knife can then moveback almost without any resistance at all. The knife moves away with hardlyany resistance after the triggering pressure has been reached. This protectsboth the knife and its edge.

● Small stones either fall away through the transfer plates, or can pass throughthe cutting system no problem. With larger stones the knives deflect back.This type of security system is not only extremely reliable, it also ensuresthat the knives remain sharp.

Präcision

100% cutThe knives penetrateright between thescrapers.No uncut forage canpossible bypass theknives into the trailer.

Pöttinger knifegrinding bench forself-loading wagonknives. Solid, stabletable with electricmotor. Grinding discmounted on parallelo-gram arms. All jointsfitted with sealedbushes.Precision blade shar-pening in seconds:sharp knives cut bet-ter and consume lesstractor power.

Lade_Ernte_Silo_engl 23.06.2003 9:13 Uhr Seite 9

-

10

A precise and consistentcut is the basis for best

silage quality.

That will ensure that the

cattle accept the forage,

saving on concentrates and

increasing milk yield.

Knife spacing: LADEPROFI /

ERNTEPROFI 43 mm

SILOPROFI 39 mm

The better cut – with 31 or 35Profimatic

LADEPROFI andERNTEPROFI

● ERNTEPROFITwo knife banks withpractical knife presel-ection system:

Top knife bank:4 forage quick-releaseknives (rough chop)

– 12-knife bank(16 knives)Lower knife bank:Silage choppingsystem 15 knives

● Knife combinations:4/12/15/16/19/27/31

Lade_Ernte_Silo_engl 23.06.2003 9:13 Uhr Seite 10

-

11

Knife bank pivotingStraightforward handcrank on LADEPROFIsand ERNTEPROFIs.Hydraulic systemoptional.

Convenient

Knife bank pivotingon SILOPROFIs operatedhydraulically from thecontrol panel in thetractor or from the sideof the trailer.Indicator lights showthat the knife bank ispivoted out.

or 35 knives

Chopping system pro-ven a thousand times ● No tools required to remove knives: You just

release the safety catch - remove the blade -finished.

● Each knife bank can be pivoted independently –hydraulic pivoting optional, standard equipmenton SILOPROFIs.

● SILOPROFIs feature hydraulic knife preselection.

SILOPROFI

● Hydraulic knife preselection: 0/10/35.Green forage chopping system with 10 knives for “zero grazing” or hay.

● Silage cutting system with 35 knives and 39 mm knife gap for exact silage chop.

Lade_Ernte_Silo_engl 23.06.2003 9:13 Uhr Seite 11

-

12

You'll be delivering tonnesof crop.

With one of these PROFIs

everything goes more

quickly and smoothly,

regardless of whether you

are processing forage, hay,

straw, or wilted matter.

65 cm

30 cm

35 cm

● Heavy-duty, height adjustable drawbar● Adjustable drawbar with single-acting cylinders.

65 cm clearance under the pickup for trouble-freedischarge in the clamp.Folding support wheel with automatic safetyinterlock.

With Pöttinger you'll achieve more than eve

LADEPROFI and ERNT

Lade_Ernte_Silo_engl 23.06.2003 9:14 Uhr Seite 12

-

13

Automatic interlock,drawbar does not dipwhen unhitched, nodipping in the clamp.

Nice one

Pressure impregnatedfloor boards areresistant to damp.Scraper floor boardsare tongue-in-groove,pressed into theframe, and boltedfast. Reliable fit.

Unload in no time ...● Scraper floor with aggressive channel bars for continuous

crop transport.● Heavy-duty chains and tightly spaced, bolted bars.● On ERNTEPROFIs the speed of the scraper floor can be

regulated electronically, in reverse too.● Heavy-duty scraper floor transmission for rapid discharge.● Self-closing hydraulically operated tailgate

for fast and reliable discharging.

han ever before …

Safe on the road● Frame made of high tensile fine-grained steel for coping with ultimate stress.● Solid side columns, close together, very stable.● Suitable for every crop – galvanised and coated side panels – no rust.● Tightly spaced ropes in the roof prevent loss of crop during transport.● LADEPROFI 3 G features folding metal side panel extensions for the top of

the trailer.

RNTEPROFI

Lade_Ernte_Silo_engl 23.06.2003 9:14 Uhr Seite 13

-

14

Realistically straightforward wEven during a long day anERNTEPROFI will make

things a lot easier in the

field and at the clamp. Even

green forage is placed in an

airy blanket. By using a

cross conveyor belt you can

place the forage straight at

the feed barrier too.

Also the ideal loading

wagon for zero grazing

applications.

Precision discharge● The closed version with the large shredding beaters enables you to finely

adjust the rate of discharge.● With the variable hydraulic control for the scraper floor you can deliver exact-

lywhat is required at the unloading point.● The beaters are easily removed using quick-release couplings.● The 60 cm wide conveyor belt is normally stowed away under the trailer. In

operation it runs at high speed (3.7 m/sec) and really projects the material.● Operates to the left or right, controlled hydraulically, practical for unloading

right at the feed barrier.● Split cross conveyor belt is also available for unloading on both sides

simultaneously.

Just one person can do the whole job

Lade_Ernte_Silo_engl 23.06.2003 9:14 Uhr Seite 14

-

15

rd with ERNTEPROFI

The control box foroperating the un-loading functions canbe mounted eithernext to the frontcontrol box, or at thetailgate.

The third beater islowered automaticallywith the roof exten-sion – no problem forlow clearances.

ole job

Every ERNTEPROFI fea-tures electronic controlsThe front end controlbox for the loadingfunctions is always inthe cab:for pickup, drawbar, roofextension, scraper floorand tailgate.The two control panelscan be joined to form aneat unit.

Comfort all round

LADEPROFI comfortSELECT CONTROLOne-finger operationAll hydraulic functionscontrolled electronicallyfrom the driver's seat –no hydraulic hoses inthe cab.Only a single connectionwith return line is requi-red on the tractor tohandle all the functions.Hydraulic controls for ● Pickup● Scraper floor● Tailgate● Drawbar● ExtensionEvery LADEPROFI features electronic controls – so that allhydraulic functions canbe controlled at thepress of a button.

LADEPROFIHydraulic operation withmechanical preselectAll functions can becontrolled from thedriver's seat as standard:● Pickup● Scraper floor● Tailgate● Drawbar (Optional)● Extension (optional)● Cutting systems

(Optional)

Nice one

Lade_Ernte_Silo_engl 23.06.2003 9:14 Uhr Seite 15

-

16

Ensiling at record speed – SIRecord loading perform-ance, consistent cutting

length, reliable and robust

– that is how experienced

operators describe these

silage wagons.

1.80 m wide pick-up with 6

rows of tines and eight

feeding tines per bar.

The trusty SILOPROFIs meet

all the specifications from

start to finish – especially

those applying to contrac-

tors' requirements.

High stabilitySafe on the road● Frame made of high tensile fine-grained steel for coping with ultimate stress.● Solid side columns, close together. Very stable.● Wagons fitted with beater rotors have a side door for accessing the loading

chamber.

● Adjustable drawbar with double-actingcylinders.

65 cm clearance under the pickup fortrouble-free discharge in the clamp.

The adjustable drawbar and thepivoting support leg eliminate

time-consuming crankingduring hitching and

unhitching.

SILOPROFI 1SILOPROFI 23550 mm

2850 mm

Lade_Ernte_Silo_engl 23.06.2003 9:14 Uhr Seite 16

-

17

– SILOPROFIHigh capacity ● High volume body with rigid side walls for reliable discharge without brid-

ging.● Roof section can be folded down.● Also suitable for transporting wood chips.● Walls have been especially treated, no rust.● Tightly spaced ropes in the roof prevent loss of crop during transport.● Hydraulic folding roof available as option for low clearances

Automatic loading system optional● There is less stress on the driver and the load capacity is increased.

Optimised

Wagon is filledautomaticallyWith the automatic loadingsystem there is less stresson the driver and the loadcapacity is increased.

Wagons fitted withbeater rotors have aside door for accessing the loadingchamber.

Lade_Ernte_Silo_engl 23.06.2003 9:14 Uhr Seite 17

-

18

In the clamp and in the feeder ...

Silage has got to be madefast. Time and weather are

the limiting factors.

That is why a silage trailer

has got to deliver top

performance during

unloading too.

A SILOPROFI achieves that

in record time.

High performanceduring discharging● 4 scraper floor chains as standard with closely

grouped channel bars for proactive foragedischarge.

● The chains are made from high tensile strength,heat treated steel.

● Hydraulic transmission powered by tractorhydraulics, unloading without P.T.O. shaft on L-models.

● Heavy-duty scraper floor transmission for rapiddischarge.

● The speed of the scraper floor can be regulatedelectronically, in reverse too (on D-models).

● The scraper floor tensioners are easily accessibleand each chain can be adjusted individually.

● Pressure impregnated floor boards are resistantto damp.

SILOPROFI – quality tha

Scraper floor boards aretongue-in-groove,pressed into the frame,and bolted fast.Reliable fit.

Lade_Ernte_Silo_engl 23.06.2003 9:14 Uhr Seite 18

-

19

er ...

Universaly that lasts

Tailgate type-LUnloading withoutP.T.O.

Universal tailgate Hydraulic operated,self-closing, widestpossible opening fornormal operation, finedischarge for uniformunloading in clamp,setting for cross-conveyor operation

Version D: two powerful beater rotors and automatic unloading system● The beater rotor transmission is driven by heavy-duty angular gear units. The

beater rotors are chain-driven and are protected with a separate cam clutchcoupling. The beater rotors can easily be removed if required.

● The beater rotors are designed for extreme loads. The aggressive tines deliveran even blanket of forage.

● Cross conveyor belt – discharge to the left or right, straight into the feedbarrier. Cross conveyor belt stows away under the wagon.

Third beater rotor optional for extremely fine proportioning in conjunction withcross conveyor belt

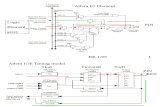

All functions can be con-trolled from the driver'sseat:The whole electroniccontrol system is wellprotected, but thehydraulics can also beoperated direct at thespool valves ifnecessary.The system is suitablefor all types of hydraulicconnection.

● Drawbar● Pickup● Knife bank pivoting system● Tailgate and beater rotors● Scraper floorPilot lights for● Cutting systems● Tailgate● Wagon level indicatorInfinitely variable speed control and automatic cut-out for scraper floor and beater rotors withautomatic unloading system.

Convenient operation

Lade_Ernte_Silo_engl 23.06.2003 9:14 Uhr Seite 19

-

20

A selection of axles and tyres

With Pöttinger you aresure to arrive at your

destination.

A total professional needs

to get from A to B quickly.

At high speed only the best

chassis available will do.

Safe and fastParabolic leaf springs (only on SILOPROFI)● Parabolic springs with large spring-to-axle spacing and bow suspension for

height compensation. Perfect suspension characteristics in the clamp, andsmooth running in the field and on the road.Sturdy linkages apply the braking and steering force.

Air brakes or hydraulic brakes (varies from country to country)● Pneumatic brake system with ALB controller (automatic load-controlled brake

system) can be upgraded to ABS as option.● High degree of safety with higher loads even with the hydraulic braking

system.● Each wheel is fitted with a brake cylinder as standard.Steered axles as option● Steered axles to protect the sward and reduce side forces while cornering.

The steered axles are locked by a separate hydraulic connection for reversingand higher speeds. Protects the tyres against wear.

Safe on the road ...

LADEPROFI/ERNTEPROFIWith 15–17 tyres thetrack width can easily bechanged from 1550 to1750 mm by turning thewheels around.On trailers with tandemaxles offsetting the trackwidths of 1550 and 1750mm will help to distribu-te the load more evenly.Single axle up to 6.9 t

355/60-R18 15,0/55-17

Wide tyresThe best size of tyre is available foreach application to keep soil com-pression as low as possible.Even in the clamp the tyres do notsink in.Less power is therefore required.8 to 10 hole rims can take the mostpunishing load.

permissibletotal weight, 25 km/hDual air brakes forsingle axle up to 5.6 tpermissible total weight,40 km/h19.0/45-17/10 PRTandem axle up to 8 ttotal permissible weight,25 km/h,Dual air brakes with ALBfor tandem axle up to 9 tpermissible weight,

Lade_Ernte_Silo_engl 23.06.2003 9:15 Uhr Seite 20

-

21

s

Neat

SILOPROFI

Twin pneumatic brakelines with ALB, 1.85 mtrack width, 8-hole rims,19.0/45-17 14 PR 11t upto 40 km/h500/50-17/14 PR 11 t upto 40 km/hSteered axle up to 11 tpermissible weight,40 km/hHigh-speed axle, 11 t

The compound sus-pension optimises theload distribution toeach axle. Whiledriving over bumpyground the forces aredistributed to bothaxles, not adsorbed bythe limit stops.Best control on slopes,even loading on eachaxle, even duringbraking.Huge leaf springsprovide the necessarysafety.

Spring suspension

tandem axles

19,0/45-17/14 500/50-17/14 555/45-177

40 km/h15.0/55-17/10 PRDual air brakes withALB for tandem axle upto 9 t permissibleweight, 80 km/h325/65 R 18

permissible weight,80 km/h555/45-17 FRT RIB8–hole rimsHigh-speed axle up to16 t,60 km/h, also with 80 km/h555/45-17 FRT RIB8–hole rims/10–holerims

Parabolic springs(only SILOPROFI)

Lade_Ernte_Silo_engl 23.06.2003 9:15 Uhr Seite 21

-

22

More details – even more inTechnical data: LADEPROFI 2 LADEPROFI 3 LADEPROFI 3 G LADEPROFI 4 ERNTEPRTotal length 7880 mm 8465 mm 8595 mm 9255 mm 7865 m

Total width 2440 mm 2440 mm 2320 mm 2440 mm 2345 m

Overall height raised 3350 mm 3400 mm 3210 mm 3440 mm 3275 m

Overall height lowered 2390 mm 2440 mm 2590 mm 2490 mm 2400 m

Loading area, mm 4750 x 1850 5340 x 1850 5350 x 1850 6130 x 1850 4750 x

Platform height 1040 mm 1090 mm 1090 mm 1130 mm 1040 m

Pickup width 1650 mm 1650 mm 1650 mm 1650 mm 1650 m

Ground clearance of pickup 350 mm 350 mm 350 mm 350 mm 350 m

Ground clearance of pickup with adjustable drawbar 650 mm 650 mm 650 mm 650 mm 650 m

Number of knives 31 31 31 31 31

Maximum knife spacing 43 mm 43 mm 43 mm 43 mm 43 m

Capacity 35 m3 39 m3 39 m3 45 m3 32 m

Volume according to DIN 11741 22,4 m3 25,1 m3 24,4 m3 28,6 m3 20 ,7

Approx. weight 2750 kg 3300 kg 3400 kg 3450 kg 3400

Lade_Ernte_Silo_engl 23.06.2003 9:15 Uhr Seite 22

-

23

re information

Easy to serviceA central lubricationmanifold at the sideof the wagon makes iteasy to lubricate thebearings on thescraper floor andbeater rotors.

MaintenanceERNTEPROFI 2 ERNTEPROFI 3 SILOPROFI 2 D/L SILOPROFI 3 D/L

7865 mm 8450 mm 8550 / 8583 mm 9235 / 9260 mm

2345 mm 2345 mm 2380 mm 2380 mm

3275 mm 3325 mm 3470 mm 3540 mm

2400 mm 2450 mm 2615 mm 2685 mm

4750 x 1850 5340 x 1850 5100 x 1850 mm 5800 x 1850 mm

1040 mm 1090 mm 1150 mm 1220 mm

1650 mm 1650 mm 1800 mm 1800 mm

350 mm 350 mm 350 mm 350 mm

650 mm 650 mm 650 mm 650 mm

31 31 35 35

43 mm 43 mm 39 mm 39 mm

32 m3 37 m3 40 / 42 m3 45 / 47 m3

20 ,7 m3 23,7 m3 24,3 / 26,2 m3 27,3 / 29,2 m3

3400 kg 3950 kg 5100 kg / 4800 kg 5300 kg / 5000 kg

Lade_Ernte_Silo_engl 23.06.2003 9:15 Uhr Seite 23

-

Alois Pöttinger Maschinenfabrik Ges.m.b.H.Industriestraße 1A-4710 Grieskirchen phone +43 (0) 7248/600-325fax +43 (0) 7248/600-0-513

Quality for the future

● Dip priming and powder coating provide automotive-quality paint work

● Laser cutting machines – highest precision● New hardening facility for wear parts● Latest 3-D design

Machines bearing the Pöttinger clover-leaf logo are successful internationally, backed by reliable quality and service.

durable paintwork

Modern automotive

paint shop flexible

impact resistant

Laser cutting machines Hardening centre 3-D design

LP-E

P-S

P/e

ng

l/01/

01 D

D

www.poettinger.at – e-mail: [email protected]

… more success with PöttingerImporter for Ireland:T. Traynor & Sons Ltd.Cashel Road, Clonmel Co. TipperaryIrelandphone 052/25 766fax 052/25 802

e-mail: [email protected]

Importer for USA:WFC COMPANIESPÖTTINGER US DIV.3867 East Highway 12Willmar, MN 56201phone 320-235-8123fax 320-235-6325

e-mail:[email protected]

Importer for Canada:Gallignani Falc Dist. Inc.640 Chaveau DrummondvilleCDN-J2C 6C9 Québecphone 819/477-1107fax 819/477-1108

e-mail: [email protected]

Importer for Australia:Strautmann Australia Pty LtdLot 9, Dryden CourtAUS-3442 Woodend.Victoriaphone 03 5427 3088fax 03 5427 3378

e-mail: [email protected]

Importer for GB:LandMec PottingerCantrell WorksBittaford, IvybridgeDevon PL21 OEZEnglandphone 01752 891285fax 01752 891392 e-mail: [email protected]

Lade_Ernte_Silo_engl 23.06.2003 9:15 Uhr Seite 24