EricPierceBrownPortfolioBook-07-Sm

-

Upload

eric-brown -

Category

Documents

-

view

47 -

download

0

Transcript of EricPierceBrownPortfolioBook-07-Sm

Eric Pierce BrownGraphic [email protected]

Eric Pierce BrownGraphic [email protected]

Eric Pierce BrownGraphic [email protected]

Eric Pierce BrownGraphic [email protected]

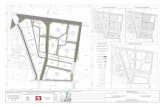

The TechNews document prior to me redesigning it

The TechNews document after I redesigning it

Phot

o by

NIO

SH

Milestones in Mining Safety and Health Technology

OFFICE OF MINE SAFETY AND HEALTH RESEARCH

TechnologyNews

No. 553 August 2015

Interactive BG 4 Training Software Reinforces Skills for Benching Mine Rescue Breathing ApparatusSummaryAn effective training tool, the BG 4 Benching Trainer software, now helps to reinforce the critical skills that mine rescue team members must possess to accurately “bench” closed-circuit breathing apparatus. This software supplements traditional hands-on training through a 3D interactive environment in which rescue personnel can practice benching a virtual Draeger BG 4 apparatus. Knowledge of critical benching skills helps in maintaining the integrity of breathing apparatus and in keeping mine rescue team members safe during mine emergencies.

By Jason Navoyski, Michael Brnich, CMSP, and Timothy Bauerle

BackgroundHands-on training is the traditional method for teaching individuals how to bench a BG 4 breathing apparatus. Mine rescue team trainers typically work with new rescue team members to teach them the process of benching a closed-circuit breathing apparatus. Once they receive initial training, trainees demonstrate their proficiency by benching an apparatus from start to finish. After completing the initial training, benchmen practice benching a breathing apparatus during regular monthly mine rescue training sessions. Benching competitions at

Figure 1: Mine rescue instructor shows trainees the BG 4 Benching Trainer software.

mine rescue contest events are another method of evaluating trainee competen-cy. Despite the proven value of training with an actual breathing apparatus, a need exists to reinforce benching skills when an actual apparatus is not avail-able due to the logistics of providing the equipment and scheduling classroom time. Through feedback from mine res-cue trainers and team members, the National Institute for Occupational Safety and Health (NIOSH) determined that a critical need exists for new approaches to benchmen training. To address this need, NIOSH developed the BG 4 Bench-ing Trainer software. The new software serves as a supplemental method of introducing new mine rescue team members to the Draeger BG 4 apparatus and guiding them through the benching process in a 3D interactive environment. Trainers can use the software to teach trainees (see Figure 1) about the differ-

ent parts that make up the apparatus, the potential flaws in each part, and how to install the parts. Although not a substi-tute for hands-on training, the software allows rescue team members to practice benching a BG 4 apparatus outside of traditional training sessions with the help of realistic 3D models. NIOSH developed this software as part of a suite of train-ing applications using 3D interactive environments for teaching critical think-ing skills to miners. Other applications in the suite include Underground Coal MineMap Reading Training

(http://www.cdc.

gov/niosh/mining/works/coversheet1825.html), which was released in 2009, and Mine Emergency Escape Training (planned for 2016).

About the New SoftwareNIOSH software developers designed the BG 4 Benching Trainer module to emu-late the BG 4 benching process, allowing

The TechNews document prior to me redesigning it

users to interact with realistic 3D apparatus parts within a 3D interactive environment. The software places the trainee in front of a virtual table where all of the BG 4 apparatus parts are shown. The trainee selects parts from the virtual table one at a time with each part gliding into view for closer inspection. Figure 2 shows the breathing air bag being inspected through the software. The trainee inspects each individual part for flaws with the inspection tools provided in the software. Most apparatus part flaws are visual and require an attention to detail to find, just like in the real-world benching competi-tions where judges introduce actual flaws in breathing appara-tus parts for benchmen to find. In the software, apparatus part flaws range from a ripped breathing bag to missing O-rings. When a trainee finds a flaw, they can swap it for a replacement part as they normally would in a real-life mine rescue benching contest. Once fully assembled, the trainee can test the BG 4 for leaks using the virtual RZ tester. Figure 3 illustrates the BG 4

Figure 2: The breathing air bag selected for inspection within the software.

Figure 3: A completely assembled virtual BG 4 attached to the RZ tester unit within the software.

completely assembled within the software and attached to the virtual RZ tester. The software generates a score sheet for the trainee, which the trainer can use to review a trainee’s performance and provide post-training feedback.

The portability of downloading the software onto a PC allows mine rescue team members to practice benching techniques without the need to use an expensive, live apparatus. This provides greater training flexibility and more opportunities to become familiar with the apparatus outside of hands-on training sessions.

Field Test ResultsThirty mine rescue team members participated in the field test evaluation of the software. Participants had an average of 1.85 years of apparatus benching experience. Experience levels ranged from zero to seven years, with nearly 67% of trainees having one year or less of benching expertise. Following each field test session trainees filled out a post-training question-naire to provide feedback regarding their training experience and opinions on the effectiveness of the software. Mine rescue team members and benchmen who participated in the testing provided mostly positive feedback:

• 87% agreed that the training software reinforcedknowledge and skills learned through previous minerescue training.

• 84% agreed that the training software made them moreconfident in having the ability to correctly bench a BG 4during a real mine emergency.

• 71% agreed that the training software helped to preparethem for a benching competition.

• 94% agreed that the training software motivated them tolearn about benching a BG 4.

• 94% agreed that training in a virtual environment is a goodsupplement to training in a real-life environment.

How to Obtain the BG 4 Benching Trainer SoftwareThe software is now available for download at no cost from the NIOSH OMSHR website at http://www.cdc.gov/niosh/mining/Works/coversheet1877.html.

For More InformationFor more information on BG 4 Benching Trainer software, contact Jason Navoyski, [email protected], 412-386-5041, or the Health Communica-tions Coordinator ([email protected]), NIOSH Office of Mine Safety and Health Research, 626 Cochrans Mill Road, Pittsburgh, PA 15236.

To receive NIOSH documents or for more information about occupational safety and health topics, contact: 1-800-CDC-INFO (1-800-232-4636), 1-888-232-6348 (TTY), or request information at the CDC website at www.cdc.gov/info, or visit the NIOSH website at www.cdc.gov/niosh.

DHHS (NIOSH) Publication No. 2015–225

The TechNews document after I redesigning it

Figure 1: Two new manufactured cylinders that meet DOT requirements for use in SCSRs.

Need for Improved Breathing Air Supply (BAS) TechnologiesLegislation (the Mine Improvement and New Emergency Response Act of 2006) and recent technology advancements (survivable voice communications systems) have demonstrated a need to move SCSR technology to a next-gen-eration status. In response to this need, NIOSH’s Office of Mine Safety and Health Research (OMSHR) established a Breathing Air Supplies (BAS) program to develop components that could be used in next-generation SCSR devices by:

►allowing users to change between SCSRs and between SCSRs and self-contained breathing apparatus (SCBAs) via docking/switch-over valves without exposure to an irrespirable atmosphere ►enabling verbal communications by users through the use of hoods with inner masks ►addressing performance efficiency improvements in SCSRs by focusing on design areas such as CO2 absorber optimization, oxygen flow control, and breathing loop heat removal ►providing more ergonomic SCSR designs to improve user experi-ence by developing smaller very high-pressure cylinders, compact reducers, and symmetric load distri-bution ►exploring alternative solutions to SCSRs caches along the escape route (e.g., SCBAs with air refill stations)

This Technology News describes one part of this multi-prong effort—the develop-ment of very high-pressure cylinders.

Very High-Pressure Oxygen CylindersSCSRs used in mines for self-escape post-disaster store and generate oxy-gen in two ways, leading to two design types: chemical oxygen-generating types using potassium superoxide (KO2) and types using gaseous oxygen stored in a compressed form in high-pressure cylinders. Current high-pressure oxygen cylinders used in NIOSH/MSHA-approved “one-hour” SCSRs store oxygen at 3,000 psi (206 bar) and are manufactured out of aluminum or composite materials. Stainless steel cylinders used in NIOSH/MSHA-approved “10-minute” SCSRs store oxygen at 3,850 psi (265 bar). With advances in materials science, two im-portant opportunities exist: (1) to notably reduce the size and weight of cylinders filled to 3,000 psi, and (2) to significantly improve cylinder capacity by increasing cylinder fill pressure.

New materials have allowed for a reduced size and weight of compressed gas cylinders that store pure oxygen at high pressures, giving manufacturers of closed-circuit self-contained self-res-cuers (SCSRs) improved options for meeting the new standard for oxygen consumption requirements set forth in 42 CFR Part 84 Subpart O. These newly designed very high-pressure cylin-ders—currently Department of Trans-portation (DOT)-certified for oxygen duty to 3,000 psi and now available in two sizes—will enable manufacturers to reduce the overall size and weight of future SCSR units by incorporating these cylinders in their designs. Using this new cylinder technology at 3,000 psi represents a significant advance-ment, affording greater SCSR design flexibility by allowing manufacturers to choose between cylinders with two length dimensions, using them singularly or in combination, which will enable different capacities and therefore different operational dura-tions for SCSR designs. Moreover, the new cylinder technology was designed to be capable of meeting DOT certifica-tion for 5,000 psi oxygen duty. There-fore, SCSR manufacturers can pursue DOT certification for use at 5,000 psi to further reduce the size and weight of their devices beyond what is already achievable at 3,000 psi.

By Rohan Fernando

Summary

New Very High-Pressure Oxygen Cylinders for Use in Closed-Circuit Self-Contained Self-Rescuers (SCSRs)

No. 55X Month 2015

Milestones in Mining Safety and Health Technology

OFFICE OF MINE SAFETY AND HEALTH RESEARCH

TechnologyNews

The TechNews document after I redesigning it

For More Information

To receive NIOSH documents or for more information about occupational safety and health topics, contact: 1-800-CDC-INFO (1-800-232-4636), 1-888-232-6348 (TTY), or request information at the CDC website at www.cdc.gov/info, or visit the NIOSH website at www.cdc.gov/niosh.

DHHS (NIOSH) Publication No. 2015–xxx

For more information on this topic, contact Rohan Fernando, [email protected], 412-386-6619, or the Health Communications Coordinator ([email protected]), NIOSH Office of Mine Safety and Health Research, 626 Cochrans Mill Road, Pittsburgh, PA 15236.

Cylinder

Nominal water volume (cubic inches)

Length (inches)

Diameter (inches)

Oxygen volume (liters) at service pressure (psi)

Luxfer L3B 19.7 6.5 2.7 98 L at 5,000 psi70 L at 3,000 psi

Luxfer L3C 28.1 8.5 2.7 140 L at 5,000 psi101 L at 3,000psi

Table 1. Cylinder oxygen capacities at different pressures

This pressure is within the capability of current oxygen-filling equipment, such as booster pumps.

New Cylinder SpecificationsThe new cylinders are fully wrapped filament-wound compos-ite pressure vessels designed for a maximum service pressure of 5,000 psi (345 bar) and an operating service life of 15 years. They are constructed of a carbon fiber/epoxy resin composite overwrap of a 6061-T6 aluminum alloy liner. The outermost wrap of the cylinders consists of an S2-glass fiber/epoxy resin composite for abrasion protection.

The cylinders have one port with an internal neck thread with an O-ring seal to accept a shut-off valve and/or pressure regu-lator. Both cylinders were manufactured by Luxfer Gas Cylin-ders, Riverside, CA, to the following specifications: maximum service pressure of 3,000 psi (206 bar) for containing oxygen; maximum service pressure of 5,000 psi (345 bar) for contain-ing air, argon, carbon dioxide, helium, hydrogen, methane, nitrogen, and nitrous oxide; test pressure of 8,333 psi (575 bar); approval by DOT SP-10915; qualification tests according to DOT-CFFC; thread form of 0.625-18 UNF-2B.

The following additional specifications apply to the Luxfer L3B cylinder: nominal diameter of 2.7 in (68.6 mm); nominal length of 6.5 in (164 mm); water volume of 19.7 cu in (0.32 liters); maxi-mum weight (empty) of 1.1 lb (0.50 kg).

The following additional specifications apply to the Luxfer L3C cylinder: nominal diameter of 2.7 in (68.6 mm); nominal length of 8.5 in (216 mm); water volume of 28.1 cu. in (0.46 liters); maxi-mum weight (empty) of 1.3 lb (0.58 kg).

The material used in cylinder manufacture is oxygen compat-ible; however, cylinders must be internally cleaned for oxygen service according to MIL1330 or an equivalent standard before being integrated into a breathing apparatus.

Certification TestingAs part of the qualification process, the cylinders underwent a series of tests according to DOT-CFFC procedures. These were the hydrostatic test, hydraulic burst test, drop test, cycling test at ambient temperature, environmental cycle test, thermal cycle test, gunfire test, and bonfire test. The cylinders were tested at the Riverside, CA, site where the DOT has established a testing facility. Design approval certificates were issued for both cylinder types per DOT-SP10915, allowing the cylinders to be filled with compressed gas to 3,000 psi (206 bar).

Limitations/RestrictionsThe current DOT approval for these newly developed cylinders allows a maximum service pressure of 3,000 psi (206 bar) for containing pure oxygen, which is the gas used in closed-cir-cuit SCSR designs. The 5,000 psi (345 bar) pressure rating is for containing air and other gases. DOT approval for the 5,000 psi (345 bar) oxygen rating is being pursued by NIOSH, but until such approval is granted, these cylinders should be limited to a service pressure of 3,000 psi (206 bar).

New Cylinder DesignsTwo sizes of carbon composite cylinders with aluminum liners were manufactured (see Figure 1) to meet all relevant U.S. De-partment of Transportation (DOT) regulations. The capacity (or useable oxygen volume) to be contained in the cylinders was determined by considering two relevant standards:

► the oxygen consumption stated in the capacity and performance tables in 42 CFR Part 84 Subpart O—i.e., three capacity ratings defined in relation to volume of oxygen (in liters) available in the device as Cap 1 (20 ≤ L ≤ 59), Cap 2 (60 ≤ L ≤ 79), and Cap 3 (L ≥ 80); ► the one-hour duration required by 30 CFR Part 75 for self-rescue devices used in mine escape applications.

To allow smaller cylinders to be used in an SCSR with a nom-inal duration of one hour or one-half hour while meeting the oxygen consumption requirements in 42 CFR Part 84 Subpart O, the design criterion for maximum service pressure was set at 5,000 psi (345 bar). Two cylinder sizes were selected to con-tain oxygen with expanded volumes (at 1 atmosphere) of 140 liters and 98 liters, respectively, at this pressure. Table 1 lists the oxygen capacities at different pressures for the two newly manufactured cylinders—the Luxfer L3B and Luxfer L3C. For fill capacities of both 3,000 and 5,000 psi, the cylinders also provide a significant reduction in size and weight from that which is currently available on the market. The new cylinders described in this document represent a significant opportunity for SCSR manufacturers to address the size and weight concern in new SCSR designs. As an example, when considering only

the 3,000 psi fill capacity, one could now develop a smaller and lighter Cap 3 device by using the L3C cylinder filled only to 3,000 psi. Moreover, as manufacturers design their SCSRs to meet the new standard, the need for a different layout/shape or longer-duration (140 L) Cap 3 SCSR may be desirable. In this instance, a manufacturer has the option of using two L3B cylinders in combination, each filled at 3,000 psi. In addition to the size and weight improvements discussed above when the cylinders are filled to only 3,000 psi, additional improvements will also be achievable if a manufacturer pursues DOT certifica-tion for filling to 5,000 psi. For this same example cited above, the L3C cylinder can be replaced with the L3B cylinder when pressurized to 5,000 psi, thus making the SCSR still smaller due to the reduced cylinder size for the same duration. The 5,000 psi (345 bar) service pressure rating allows the required quan-tity of oxygen to be stored in a cylinder that could be used in a person-wearable one-hour SCSR despite the degrading effects of the compressibility factor of oxygen at that pressure.

The TechNews document after I redesigning it

RI 9694REPORT OF INVESTIGATIONS/2014

Investigation of Purging and Airlock Contamination

of Mobile Refuge Alternatives

Investigation of Temperature Rise in Mobile Refuge Alternatives

RI 9695REPORT OF INVESTIGATIONS/2014

RI 9697 REPORT OF INVESTIGATIONS/2015

Shotcrete Design and Installation Compliance Testing: Early Strength, Load Capacity, Toughness, Adhesion Strength, and Applied Quality

RI 9698 REPORT OF INVESTIGATIONS/2015

FFacilitaacilitating the Uting the Use ofse of Built-in-placBuilt-in-place Refuge Ae Refuge Altlternaernativtiveses in Min Minesines

Mining Ergonomics Audit

E

Mining

EAuditErgonomics

Mobile App Title Design

App Store page Design Concept

Mobile app icon design

Mobile app icon design

exus

exus

Inte

rnal

Pro

gram

Lo

go D

esig

n

OFF

ICE O

F MIN

E SA

FETY

AN

D HE

ALT

H RE

SEA

RCH

ww

w.c

dc.g

ov/n

iosh

/min

ing

We

have

loca

tions

in:

Bruc

eton

, PA

Spok

ane,

WA

(n

ear P

ittsb

urgh

, PA)

• Phy

sics

• Che

mis

try

• Soc

ial s

cien

ces

• Com

mun

icat

ion

The

NIO

SH m

inin

g pr

ogra

m e

mpl

oys

peop

le in

the

follo

win

g di

scip

lines

:

• Eng

inee

ring

min

ing

• che

mic

al •

mec

hani

cal

el

ectr

ical

• bi

omec

hani

cal

• Inf

orm

atio

n te

chno

logy

• Pro

gram

adm

inis

trat

ion

Inte

rest

ed in

a c

aree

r in

Min

e Sa

fety

And

Hea

lth?

Seeking a position as a

Mechanicalengineer?The NIOSH Office of Mine Safety and Health Research has positions to fill in these locations:

Bruceton, PA (near Pittsburgh, PA)

Spokane, WA

More Information:[email protected]/niosh/mining/aboutus/employment.html

Office Of Mine Safety and HealtH ReSeaRcHwww.cdc.gov/niosh/mining

Office Of Mine Safety and HealtH ReSeaRcHwww.cdc.gov/niosh/mining

Seeking a position as a

Mechanicalengineer?The NIOSH Office of Mine Safety and Health Research has positions to fill in these locations:

Bruceton, PA (near Pittsburgh, PA)

Spokane, WA

More Information:[email protected]/niosh/mining/aboutus/employment.html

Seeking a position as a

Miningengineer?The NIOSH Office of Mine Safety and Health Research has positions to fill in these locations:

Bruceton, PA (near Pittsburgh, PA)

Spokane, WA

More Information:[email protected]

Office Of Mine Safety and HealtH ReSeaRcHwww.cdc.gov/niosh/mining

Office Of Mine Safety and HealtH ReSeaRcHwww.cdc.gov/niosh/mining

Seeking a position as a

Miningengineer?The NIOSH Office of Mine Safety and Health Research has positions to fill in these locations:

Bruceton, PA (near Pittsburgh, PA)

Spokane, WA

More Information:[email protected]/niosh/mining/aboutus/employment.htmlwww.cdc.gov/niosh/mining/aboutus/employment.html

SP

AR

TA

NA

UT

OM

OT

IVE

AU

TO

MO

TIV

EP

AR

TA

NS

Aut

hori

zed

Dea

ler

For

All

Bran

ds

CA

M2

Supe

rPro

Max

Sy

nthe

tic B

lend

1 qu

art-1

2 Pe

r Cas

eA

vaila

ble

in 5W

-20, 5

W-30

, 10

W-30

, 10W

-40,

20W-

50,AT

F

$24

.99

MO

BIL

1Fu

ll Sy

nthe

tic

Mot

or O

il 1

quar

t-6 P

er Ca

seA

vaila

ble

in 0W

-40,

0W-20

, 5W

-30,

10W-

30, 5

W-40

M,5W

-20

$36

.99

SHEL

L M

otor

Oil

1 qu

art-1

2 Pe

r Cas

eA

vaila

ble

in 5W

-20, 5

W-30

, 10

W-30

, 10W

-40,

20W-

50,AT

F

$29.

50

Con

oco

Ph

illp

s55

Gal

lon

Dru

m

Ava

ilabl

e in

All

Wei

ghts

†, B

eaco

n††

†$425.0

0

††$369.

00

Con

oco

Ph

illp

sSy

nthe

tic B

lend

Mot

or O

il1 q

uart-

12 P

er Ca

seA

vaila

ble

in 5W

-20, 5

W-30

, 10

W-30

, ATF

$25.9

9Lu

cas

Oil

Stab

ilize

r

$10

4.9

5Lu

cas

Tran

smis

sion

Fix

$114

.95

Luca

sFu

el T

reat

men

t

$79.

95

Ken

da

llFu

ll Sy

nthe

tic M

otor

Oil

1 qua

rt-12

Per

Case

5W-2

0, 5W

-30,1

0W-3

0—$45

.99

5W-4

0— $

59.

99

0W-20

— $

49.

99

Synt

hetic

Ble

nd M

otor

Oil

Full

Synt

hetic

Mot

or O

ilFu

ll Sy

nthe

tic M

otor

Oil

Ava

ilabl

e in

Oil

Filte

r

$18

.99

1-8

00

-536

-970

7 |

1

-718

-829-3

90

3Ma

in Nu

mber:

PER

CASE

:

PER

CASE

:

PER

CASE

:

EACH

EACH

PER

CASE

:

Fax

Numb

er:

AN

CO

Wip

er B

lade

sA

vaila

ble

in Al

l Size

s 16

"-24"

$2.9

926

"-28"

$3

.99

BO

SCH

Evo

luti

on

Wip

er B

lade

sA

vaila

ble

in Al

l Size

s 16

"-24"

$9.9

526

"-28"

$10.9

5

AN

CO

AN

CO

BO

SCH

Evo

luti

on

SP

AR

TA

NA

UT

OM

OT

IVE

AU

TO

MO

TIV

EP

AR

TA

NS A

vaila

ble

in

STP

® fu

el ad

ditive

&

Oil T

reat

ment

Supe

r C

once

ntra

ted

Fuel

Inje

ctor

-BL

AC

K

$29.

99

Fuel

Inje

ctor

&

Car

bure

tor

Trea

tmen

t - W

HIT

E

$22

.99

Com

plet

e Fu

elSy

stem

Cle

aner

-SI

LVER

$56

.99

Gas

Tre

atm

ent -R

ED

$19.

99

Oct

ane

Boos

ter

-OR

AN

GE

$42

.99

Oil

Trea

tmen

t -B

LUE

$32

.99

MID

WES

T G

as C

ans

-34

-34 G

OLD

$37.

99

$45

.99

Ant

ifree

ze

DW

-1 A

TF

$69.

99

$69.

99

HEA

TWA

VE

SUM

MER

CO

OLA

NT

$13

.99

ASS

OR

TED

CH

EMIC

ALS

Pow

er S

teer

ing—

$13

.99

Brak

e Fl

uid—

$18

.99

GU

MO

UT

7518

—$2

1.9

9

TURB

O 1

08

—$37.

99

AR

MO

R A

LL 4

oz.

—$3

4.9

9

AR

MO

R A

LL 1

0oz.

—$39.

99

FIX

a FL

AT—

$29.

99

HO

ND

AO

.E.

PR

IDE

Ant

ifree

ze -34

$22

.99

-34 R

ED

-34 G

OLD

$27.

99

$27.

99

1-G

allo

n—

$6

.75

2-G

allo

n—

$7.7

55

-Gal

lon

—$1

1.75

PEA

K

Ant

ifree

ze

Aut

hori

zed

Dea

ler

For

All

Bran

ds

1-8

00

-536

-970

7 |

1

-718

-829-3

90

3Ma

in Nu

mber:

Fax

Numb

er:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:PE

R CA

SE:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

FLX

-Wip

er B

lade

s

All Si

zes 16

"-24"

$5

.95

26"-2

8" $

6.9

5

SPARTAN

AUTOMOTIVE

AUTOMOTIVE

PARTAN

S

Aut

hori

zed

Dea

ler

For

All

Bran

ds

CA

M2

Supe

rPro

Max

Sy

nthe

tic B

lend

1 qu

art-1

2 Pe

r Cas

eA

vaila

ble

in 5W

-20, 5

W-30

, 10

W-30

, 10W

-40,

20W-

50,AT

F

$24

.99

MO

BIL

1Fu

ll Sy

nthe

tic

Mot

or O

il 1

quar

t-6 P

er Ca

seA

vaila

ble

in 0W

-40,

0W-20

, 5W

-30,

10W-

30, 5

W-40

M,5W

-20

$36

.99

GU

LFM

otor

Oil

1 qu

art-1

2 Pe

r Cas

eA

vaila

ble

in 5W

-20, 5

W-30

, 10

W-30

, 10W

-40,

ATF

$25.9

9

INTR

OD

UC

ING

Luca

sO

il St

abili

zer

$10

4.9

5Lu

cas

Tran

smis

sion

Fix

$114

.95

Luca

sFu

el T

reat

men

t

$79.

95

Oil

Filte

r

$17.

99

1-8

00

-536

-970

7 |

1

-718

-829

-39

03

Main

Numb

er:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

Fax

Numb

er:

Ken

da

llFu

ll Sy

nthe

tic M

otor

Oil

1 qua

rt-12

Per

Case

5W-2

0, 5W

-30,1

0W-3

0—$45

.99

5W-4

0— $

64

.95

0W-20

— $

49.

99

Ken

da

llSy

nthe

tic B

lend

Mot

or O

il1 q

uart-

12 P

er Ca

seA

vaila

ble

in 5W

-20, 5

W-30

, 10

W-30

, 10W

-40,

20W-

50,AT

F

$26

.99

Com

ple

te L

ine

STO

CK

ED

CA

LL F

OR

PR

ICIN

G D

ETA

ILS

AN

CO

Wip

er B

lade

sA

vaila

ble

in Al

l Size

s 16

"-24"

$2.7

526

"-28"

$3

.75

BO

SCH

Evo

luti

on

Wip

er B

lade

sA

vaila

ble

in Al

l Size

s ST

ARTI

NG A

T

$6

.99

Wip

er B

lade

sA

vaila

ble

inAN

CO

Wip

er B

lade

sA

vaila

ble

in

$2.7

5

$3

.75

SPARTAN

AUTOMOTIVE

AUTOMOTIVE

PARTAN

S BO

SCH

Evo

luti

on

AN

CO

AN

CO

Supe

r C

once

ntra

ted

Fuel

Inje

ctor

-BL

AC

K

$29.

99

Fuel

Inje

ctor

&

Car

bure

tor

Trea

tmen

t -W

HIT

E

$22

.99

Gas

Tre

atm

ent -R

ED

$19.

99

Oct

ane

Boos

ter

-O

RA

NG

E

$42

.99

MID

WES

T G

as C

ans

DEX

-COO

L Un

iversa

l

$45

.99

$45

.99

Ant

ifree

ze

DW

-1 A

TF

$69.

99

$69.

99

ASS

OR

TED

CH

EMIC

ALS

Pow

er S

teer

ing—

$14

.99

Brak

e Fl

uid

syn—$1

9.9

9

Brak

e C

lean

er—$2

5.9

9

2+2 C

arb

Cle

aner—$31

.99

FIX

a FL

AT—

$28

.99

HO

ND

AO

.E.

PR

IDE

Ant

ifree

ze -34

$23

.99

DEX-

COOL

Un

iversa

l

$28

.99

$2

8.9

9

1-G

allo

n—

$7.5

02

-Gal

lon

—$8

.99

5-G

allo

n—

$12

.99

-34

$35

.99

1-8

00

-536

-970

7 |

1

-718

-829

-39

03

Main

Numb

er:Fa

x Nu

mber:

Pow

er S

teer

ing —

$35

.99

TEC

HR

ON

$3

3.9

9

Ask A

bout

Our

20+

Case

Dea

ls (S

pecia

l Pric

ing on

Pur

chas

e of 2

0 or m

ore c

ases

ask f

or de

tails

)

Aut

hori

zed

Dea

ler

For

All

Bran

ds

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:

PER

CASE

:PE

R CA

SE:

PER

CASE

:

PER

CASE

:PE

R CA

SE:

PER

CASE

:

PER

CASE

:PE

R CA

SE:

PER

CASE

:

PER

CASE

:

The Society for Mining, M

etallurgy &

Exploration Inc. (SME) 2015.

Exhibit event

The Society for Mining, M

etallurgy &

Exploration Inc. (SME) 2015.

Exhibit event

The Society for Mining, Metallurgy & Exploration Inc. (SME) 2016. Exhibit event

The Society for Mining, Metallurgy & Exploration Inc. (SME) 2016. Exhibit event

This is the before image the task is to

remove the big red box (literally that’s w

hat I was

asked ) after further investigation I discovered what

it was going to be used for

Having determ

ined what they w

ant out of the image

I decided that if I create a clipping mask around w

hat they w

ant to keep and extracted it out and us the gradient tool to create the illusion of a floor plane and back w

all plane w

ithin Photoshop the image w

ill be used in a industry publica tion m

ining with possible later use on the N

IOSH

M

ining government w

ebsite.

Eric Pierce BrownGraphic [email protected]

Eric Pierce BrownGraphic [email protected]

Eric Pierce BrownGraphic [email protected]

Eric Pierce BrownGraphic [email protected]