GP_Clase1

-

Upload

paola-rivas -

Category

Documents

-

view

218 -

download

0

Transcript of GP_Clase1

-

8/2/2019 GP_Clase1

1/28

Ph.D. Indira Guzman

-

8/2/2019 GP_Clase1

2/28

Objetivos de la clase El estilo APA

Ejercicio sobre APA para la proxima clase

Conceptos Principales Definicion de Proceso (make your choice)

Identificacion de un Proceso y su descripcion

Importancia de las Representaciones

Importancia de la materia: Objetivos

Presentaciones

-

8/2/2019 GP_Clase1

3/28

Lewis Charles Quintero BeltrnIngeniero de Productividad y

Calidad

Una serie de tareasde valor agregado que

se vinculan entre s paratransformar un insumo en un

producto. (Bien o Servicio)

-

8/2/2019 GP_Clase1

4/28

Any set ofactivities that when taken together,transforma series ofinputs into an output,producing a result ofvalue to a customer

Process

Input

Output

Suppli

ers

Custom

er

SIPOC

-

8/2/2019 GP_Clase1

5/28

Lewis Charles Quintero BeltrnIngeniero de Productividad y

Calidad

-

8/2/2019 GP_Clase1

6/28

Las empresas crean y entregan valor en laforma de un producto o servicio que ofrecen asus clientes o a otras empresas. Estosproductos o servicios son creados mediante

una secuencia de tareas o actividades quetoman una serie de entradas (inputs) y losconvierten en las salidas deseadas (outputs).

Los pasos de un PROCESO

Input Paso1

Paso3

Paso3

Output

-

8/2/2019 GP_Clase1

7/28Ref. Quintero Beltrn

Porque las empresas y/oorganizaciones son tan eficientes

como lo son sus procesos. Lamayora de organizaciones quehan tomado conciencia de esto

han reaccionado ante laineficiencia.

-

8/2/2019 GP_Clase1

8/28

Institute for Certification ofComputing Professionals

Kewal Dhariwal 2008 8

Business Process Management BPM goals are to efficiently align the

organization with the customers wants andneeds

BPM attempts to continuously improveprocesses seeking process optimization by Defining Measuring

Improving your process

-

8/2/2019 GP_Clase1

9/28

Procesos

Procesos

Procesos

Procesos

Coordinacin

NivelEstratgic

o

NivelAdministrativo

Nivel deConocimiento

NivelOperativo

Ventas yMarketing

Produccin

Finanzas Contab RecursosHumanos

SistemasEmpresariales

SistemasAdm.Conocimiento

Sistemas de adm. dela cadena de abastecimiento

Sistemas de adm.de Las relacionescon el cliente

Hardware SoftwareTecnologa dedatos yalmacenamiento

Redes

Arquitecturade Informacinde la organizacin

Socios deNegocios,proveedores

InfraestructuraDe TI

Arquitectura de Informacin y Infraestructura de TI

Clientes

InfraestructuraPublica

-

8/2/2019 GP_Clase1

10/28

Institute for Certification of

Computing ProfessionalsKewal Dhariwal 2008 10

Modeling Modeling a business process is a business domain

Perfecting a business process is a staff domain.

Business modeling is Business Process Management

(BPM). Business Technology Connection

The size and complexity of tasks often requires theuse of technology to model efficiently.

Business people, especially customer facing staff mustcontrol and do the modeling.

-

8/2/2019 GP_Clase1

11/28

Institute for Certification of

Computing ProfessionalsKewal Dhariwal 2008 11

Bridging IT and Business Bringing the power of technology to business staff and

reducing their work should be the BPM group credo.

BPM is the bridge between Business and IT.

BPM systems will develop to be industry specific.

A cyclical BPM life-cycle exists: Design

Modeling

Execution

Monitoring

Optimization

-

8/2/2019 GP_Clase1

12/28

Institute for Certification of

Computing ProfessionalsKewal Dhariwal 2008 12

Process Design Identify existing processes

Design the to-be processes

Key Terms

Representations of process flow Actors within a process

Alerts & Notifications

Escalations

Standard Operating Procedures

Service Level Agreements Task hand-over mechanisms

-

8/2/2019 GP_Clase1

13/28

A documented set of procedures, guidelines, and toolsintended to develop better processes

Some Business improvement methodologies Kaizen

Lean Six Sigma Lean Six Sigma Design for Six Sigma (DFSS)

-

8/2/2019 GP_Clase1

14/28

Kaizen Lean Six Sigma Lean Six Sigma DFSS

Defined Philosophy of gradual,

incremental, andorderly continuousimprovement, creating

more value and lesswaste; emphasis on

process improvementand process control

Focus on speed,

efficiency, andelimination of waste

Data-driven

methodology focusingon reducing defects andvariability

Approach to

eliminating waste andvariation; combinesboth Lean and Six

Sigma tactics

DFSS uses tools,

training, andmeasurements to enablethe design and

development ofproducts, services, and

processes that meetcustomer expectations

at Six Sigma quality

levels

Objective Small improvements byoptimizing existing

systems

Maximizing processspeed by reducing

waste

Reduce variabilitythrough continuous

process improvement

Increase quality andreduce defects/variation

while increasingprocess speed and

efficiency

Optimize the designand development

process to achieve SixSigma quality levels

from the beginning

Requirement(s) Taking action ondeviations to

maintain processcontrol

Establishing controlthrough StandardOperatingProcedures (SOPs)

Taking action ondeviations to

maintain processcontrol

Elimination of waste(muda)

Value streammapping

Processes must be inplace

The processes mustbe predictable (in

statistical control

with normaldistribution)

The processes must

be improved byreducing variation

(continuousimprovement)

Data availability

The combination ofboth Lean and Six

Sigma tools andmethods

A new product,service, or process to

design and develop

Approach Kaizens Deming-Shewhart PDCA Cycle

Plan

Do

Check

ActDMAIC is acceptable

5S

Sort

Straighten

Scrub

Systematize

Sustain

DMAIC

Define

Measure

Analyze

Improve

Control

DMAIC; Integrate themethodologies and

tools of both Lean andSix Sigma at each

phase

DMADV

Define

Measure

Analyze

Design

Verify

-

8/2/2019 GP_Clase1

15/28

Institute for Certification of

Computing ProfessionalsKewal Dhariwal 2008 15

BPMN simple diagram (www.wikipedia.org )

http://www.wikipedia.org/http://www.wikipedia.org/ -

8/2/2019 GP_Clase1

16/28

Institute for Certification of

Computing ProfessionalsKewal Dhariwal 2008 16

BPMN larger example (www.wikipedia.org )

http://www.wikipedia.org/http://www.wikipedia.org/ -

8/2/2019 GP_Clase1

17/28

Medic Clerk Vendor OtherPatient

Provide Care

Complete PPCR Review PPCR

EMS Supv

Perform Quality

Check

Enter Data in

System

Review

Batallion Chief

Print & Mail Bills

Sort, Assemble, &Mail Bills

Remit Payment

Insurance

CompanyNeed

Insurance Info

Receive Bill &

InsuranceAuthorization

Bill & InsuranceAuthorization

ReturnInsurance

Authorization

Approved PPCR

Completed PPCR

Rework

Incomplete PPCR

Incomplete

PPCR

Complete PPCR

Enter InsuranceInformation

InsuranceInfo

On File

InsuranceCompany

Insurance Info On FilePrint & Mail Bills

Paym

Completed InsuranceAuthorization

-

8/2/2019 GP_Clase1

18/28

Lewis Charles Quintero Beltrn

Ingeniero de Productividad yCalidad

-

8/2/2019 GP_Clase1

19/28

Lewis Charles Quintero BeltrnIngeniero de Productividad y Calidad

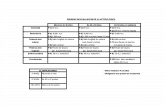

Cantidad Porcentaje

Operaciones 45 28,5%

Inspecciones 17 10,8%

Transporte 65 41,1%

Demora 22 13,9%

Almacenamiento 9 5,7%

Total de Actividades 158 100,0%

Cantidad Porcentaje

Agregan Valor 29 18,4%

No Agregan Valor 129 81,6%

Total de Actividades 158 100%

PROCESO DE COMPRAS

Requerimiento deMateriales

Verificacion deMaterial en Bodega

Aprobacion paracompra del Material

Compra de Material Recepcion deMaterialesRecepcion deMateriales

Despacho delMaterial

Pago a ProveedoresCaratersticas Generales del Proceso

Cantidad

Documentos originales que se generan 15Copias que se generan 20

Total de Documentos 35

Personas que participan en el proceso 27

Sistemas Informticos que utilizan 3

-

8/2/2019 GP_Clase1

20/28

Best is depends by the needs and current

state of your organization Best may be a combination of

methodologies

An organization ready for Six Sigma is alsoready for Lean or other methodologies

The name of methodology used doesntmatter; what matters is leadership,

commitment, vision, strategy, and follow-through from supplier to customer

-

8/2/2019 GP_Clase1

21/28

The future of business processes lies not inone methodology, but in the integration oftechnologies and methodologies in order tofacilitate execution of the process

Customers are demanding customizationsand total solutions

Innovative business processes can lead tocompetitive advantage

Business processes will drive IT

-

8/2/2019 GP_Clase1

22/28

Regardless of the methodology, start with

mapping the current processesIdentifies current state, opportunities for

improvement, process timeAllows identification of all process steps in order to

determine which steps are value added or

bottlenecksKnowing current state will assist in identifying

improvement opportunitiesAs-is vs. future process time, number of steps,

handoffs, etc.

Determine steps which add value

-

8/2/2019 GP_Clase1

23/28

Gain understanding of the process and processobjectivesAnswers who (including suppliers and customers),

what, when, where, how, and duration Identifies the information or data used in the process,

decisions, bottlenecks Identify sources of waste

Improve supplier and customer relations

Provides a common language for talking about

the process

-

8/2/2019 GP_Clase1

24/28

The future of business processes lies not inone methodology, but in the integration oftechnologies and methodologies in order tofacilitate execution of the process

Customers are demanding customizations andtotal solutions

Innovative business processes can lead tocompetitive advantage

Business processes will drive IT

-

8/2/2019 GP_Clase1

25/28

The only thing certain in business is change Industry boundaries are evaporating

The entire value chain is involved in providing

total solutions to customers: Competition

Collaboration

Partners may also be competitors

-

8/2/2019 GP_Clase1

26/28

Internal Non-compliance to Industry

Standards

Scrap

Rework

Short Cuts to Beat the System

Excess Inventory

Capacity Constraints

Low Efficiency/Productivity/Yields

Employee Symptoms

Shared Responsibility

External

Benchmarking

Company vs. World ClassPerformers

Market Share Drop

Negative Publicity Pricing Inflexibility

Warranty Costs

-

8/2/2019 GP_Clase1

27/28

1. Definir proceso con sus propias palabras2. Identifiquen un proceso del cual ustedes son

participes frequentemente.3. Describan el proceso de la manera que mejor lo

describa.4. Porque la representacin de procesos estndar

es importante?5. Que es lo que esperan aprender en esta clase? Incluir los nombres de los participantes del

grupo, el porcentaje de participacin y laactividad realizada por cada participante(moderar, tomar notas, buscar material, enviar elarchivo, transcribir, etc.).

-

8/2/2019 GP_Clase1

28/28

Traer una lista de 5 referencias (de distintotipos: electronica, revista, libro, etc.) en APAstyle relacionadas a la materia.

Incluir 2 ejemplos de formas de utilizar las

referencias dentro del texto.