El Soukkary2001

Click here to load reader

-

Upload

julio-mauricio-vidaurre-ruiz -

Category

Documents

-

view

217 -

download

1

description

Transcript of El Soukkary2001

Plant Foods for Human Nutrition 56: 365–384, 2001.© 2001 Kluwer Academic Publishers. Printed in the Netherlands.

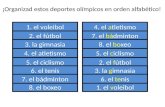

Evaluation of pumpkin seed products for breadfortification

F.A.H. EL-SOUKKARYDepartment of Food Science, Faculty of Agriculture, Minia University, El-Minia, Egypt

Received 4 November 1999; accepted in revised form 31 August 2000

Abstract. Pumpkin seed products (raw, roasted, autoclaved, germinated, fermented, pumpkinprotein concentrate and pumpkin protein isolate) were incorporated into wheat flour to produceblends with protein levels of 15, 17, 19 and 21%. Dough properties were evaluated by a farino-graph; loaves of breads were evaluated by a taste panel for crust color, crumb color, crumbtexture, flavor, and overall quality. Results indicated that pumpkin seed products can be addedto wheat flour up to a 17% protein level for raw, roasted and autoclaved pumpkin meal, 19%level for germinated, fermented and pumpkin protein concentrate and 21% level for pumpkinprotein isolate without a detrimental effect on dough or loaf quality. On the other hand, theaddition of pumpkin seed proteins resulted in increasing protein, lysine and mineral contentscompared to the control. While lysine and tryptophan were the first and second limiting aminoacids in the control bread, tryptophan and lysine were the first and second limiting amino acidsfor raw, roasted, autoclaved, germinated and fermented pumpkin meal; valine and lysine andvaline and total sulfur amino acids were the first and second limiting amino acids for pumpkinprotein concentrate and isolate, respectively. In vitro protein digestibility improved when thepumpkin seed proteins were added.

Key words: Amino acid profiles, Fermented pumpkin seed meal, Germinated pumpkin seedmeal, Pumpkin seed protein concentrate, Pumpkin seed protein isolate, Sensory evaluation

Introduction

In Egypt wheat flour bread represents the main source of carbohydrate formost of the people. Increasing the protein content of the wheat flour by theaddition of legumes and oil seeds (soybeans, cotton seeds, sesame, sunflower,and peanut flour) can improve the nutritional quality of bread, especially thelysine content. Baking characteristics, such as loaf volume and dough mixing[1–8], can also be improved. Pumpkin (Cucurbita moschata, variety Dickin-son) seeds could be utilized successfully as a good sources of edible protein(320 g/kg) and oil (450 g/kg) for human consumption, as well as animal food;at the same time, it minimizes waste pollution [9].

366

The seeds can be cooked and dried and served as snacks (e.g., Egypt) andmight also be cooked, ground (west Africa) and fermented for use as a flavorenhancer in gravies and soups [10].

Mansour and coworkers [8, 11–14] investigated the preparation, func-tional properties and nutritional quality of pumpkin seed meal, pumpkin pro-tein concentrate and isolate and also canola protein concentrate and isol-ate. Pumpkin and canola seed proteins exhibit unique functional properties(high water and fat absorption as well as good emulsification properties) andhigh lysine content, which suggest the ability to be incorporated in bakeryproducts.

The objective of this study was to determine the effect of partial replace-ment of wheat flour by raw pumpkin seed meal, roasted and autoclaved pump-kin seed meal, germinated and fermented pumpkin seed meal and pump-kin seed protein concentrate and isolate on the physical properties of thedough, baking quality characteristics and chemical composition, mineral con-tents and amino acid profile of bread made from the various pumpkin seedpreparations.

Materials and methods

Wheat flour. Wheat flour (all purpose) (72% extraction rate) was obtainedfrom the Alexandria Milling Company, Alexandria, Egypt. The protein con-tent of the wheat flour was 12.5%.

Pumpkin seeds. Pumpkin (Cucurbita moschata, variety Dickinson) seedswere obtained from the Agricultural Research Center, Ministry of Agricul-ture, Alexandria, Egypt. The seeds were cleaned by hand to remove brokenseeds and foreign materials. The seeds were peeled by hand.

Autoclaved pumpkin seed. Peeled pumpkin seeds were mixed with tap wa-ter (1: 10 w/v). The mixture was autoclaved at 121 ◦C for 30 min

Roasted pumpkin seed. Peeled pumpkin seeds were heated at 120 ◦C for 30min in an electric draught oven (VEM MLW Medizinische, Greate, Berlin,Germany).

Germinated pumpkin seed. Whole pumpkin seeds were sterilized by soak-ing in 75% ethanol for 1 min. The seeds were soaked in tap water for 12 h atroom temperature (∼25 ◦C). The soaked seeds were kept between thick layersof cotton cloth and allowed to germinate in the dark at room temperature for3 days. The germinated seeds were rinsed with tap water and peeled by hand.

367

Figure 1. Production of fermented pumpkin seed meal.

Fermented pumpkin seed. Pumpkin seeds were fermented according to theprocedure in Figure 1. Saccharomyces cerevisiae (commercial strain) wereobtained from the microbiological laboratory of Bisco Misr Company, Alex,Egypt, and maintained in malt extract broth

Defatted pumpkin seed meals. Defatted pumpkin seed meals of raw, auto-claved, roasted, germinated and fermented pumpkin seeds were prepared bygrinding the seeds (National Matsushita Elec. grinder Ind. Co., LTD., Japan)then extraction of the ground seeds with hexane in a Soxhlet apparatus. Hex-

368

ane was removed from the extracted ground seeds by heating at 50 ◦C for 2hThe resultant defatted meal was ground again and passed through a 400 µmsieve (Brith Standard Screen).

The processed pumpkin seeds were mashed and dried at 50 ◦C for 10h. The resultant defatted meals were kept refrigerated at 4–5 ◦C until used.The percentage of crude protein in raw, autoclaved, roasted, germinated andfermented pumpkin seed meals were 71.1, 70.2, 72.5, 73.5, and 74.9%, re-spectively.

Pumpkin seed protein concentrate. Pumpkin seed meal was extracted withpetroleum ether for 30 min (meal to solvent ratio 1: 4 w/v) followed by ex-traction with 75% ethanol for 30 min (meal to solvent ratio 1: 10 w/v). Bothextractions were carried out at room temperature. The protein concentrate wasdried using a vacuum oven (Type SPT-200, vacuum Dryer, Kraksw, Poland)at 40 ◦C for 8 h

Pumpkin seed protein isolate. The meal was extracted with 0.5% Na2CO3

solution (pH 9.5) at room temperature (solid to solvent ratio 1: 10 w/v) andthe mixture was shaken using a rotary shaker (Julabo D-7633 Seelbach, Ger-many) for 1 h. Insoluble materials were removed by centrifuging at 2515 ×g for 15 min; the supernate was acidified to pH 3.0 with 1 M HCL. Theprecipitate was neutralized to pH 7.0 using 2 M HCL. The precipitate waswashed twice with distilled water and dried using a vacuum oven at 40 ◦C for8 h. Pumpkin seed protein concentrate and isolate were determined accordingto the method of Mansour and coworkers [12]. Pumpkin protein concentrateand isolate were ground to pass through a 400 µm sieve then kept refrigerated(4–5 ◦C) until used. The crude protein content of pumpkin protein concentrateand isolate were 78.4 and 94.8%, respectively.

Preparation of pumpkin seed protein-wheat flour blends. Each of the pump-kin seed preparations partially replaced wheat flour to produce blends withfinal protein concentrations of 15, 17, 19 and 21%. Quantities of pumpkinseed proteins blended with wheat flour are presented in Table 1.

Physical properties of dough Water absorption, dough stability and doughsoftening of the various blends were determined using a Barbender Farino-graph with a 100 g mixing bowl; A.A.C.C. [15] methods were followed.

Pan bread preparation. The procedure of Pollhamer [16] was used to assessbaking and loaf volume. For each test, 50 g flour, 0.3 g dry yeast, 0.5 g saltand water (as flour blend) were incorporated. The dough was kneaded for 3min in the 100 g mixing bowel of the farinograph The dough was fermented

369

Table 1. Pumpkin wheat flour blends

Product % Pumpkin seed product in blends (g/100 g)

15% 17%1 19%2 21%3

Raw pumpkin seed meal1 4.30 7.70 11.10 14.50

Roasted pumpkin seed meal1 4.20 7.50 10.80 14.20

Autoclaved pumpkin seed meal1 4.20 7.80 11.30 14.70

Germinated pumpkin meal2 4.10 7.40 10.70 13.90

Fermented pumpkin seed meal2 4.00 7.20 10.40 13.60

Pumpkin seed protein concentrate2 3.80 6.80 9.90 12.90

Pumpkin seed protein isolate3 3.00 5.50 7.90 10.30

1,2 and 3 were conducted on breads containing these protein levels to evaluate chemicalcomposition, mineral content, amino acid profile and in vitro protein digestibility.

at 30 ◦C for 70 min in a proofing cabinet. The fermented dough was placedin a lightly oiled glass cylinder and leveled with a cylindrical piece of wood.The dough was left at 30 ◦C for 60 min in a proofing cabinet. The pan breadwas baked in an oven at 260 ◦C for 15 min. Loaf volume was measured byrapeseed displacement after cooling the bread for 1 h at room temperature(∼25 ◦C). Breads were divided into two parts, one for the sensory evaluation,and the other for chemical analysis. The latter portion was dried at 40–50 ◦Cfor 12 h in an electric air draught oven, then ground (National Matsushita ElecGrinder Ind. Co., Ltd., Japan) and passed through a 400 µm sieve. The groundsamples were packed in screw cap glass jars and left at room temperature forchemical analysis.

Sensory evaluation and loaf volume. The freshly sliced bread was cut into5 × 5 cm pieces and served to five trained staff members from the univer-sity of Minia, Minia, Egypt. Selection of panelists was based on participantinterest, taste and flavor acuity and ability to understand test procedures. In-struction score sheets for evaluating samples were given to panelists. Theywere provided with eight randomly coded samples (control bread, raw pump-kin seed meal bread, roasted pumpkin seed meal bread, autoclaved pumpkinseed meal bread, germinated pumpkin seed meal bread, fermented pumpkinseed meal bread, pumpkin seed protein concentrate bread and pumpkin seedprotein isolate bread) in four sessions for each concentration. General attrib-ute ranking evaluations were made in individual tables under fluorescent lightat ambient temperature (∼ 25 ◦C).

Panelists were instructed to rinse their mouth with water before startingand between sample evaluations. Five sensory attributes were evaluated (crustcolor, crumb color, crumb texture, flavor and overall quality) using a 5-point

370

scale, where 5 = excellent, 4 = good, 3 = satisfactory, 2 = fair, and 1= poor.Accuracy and precision were evaluated statistically.

Analytical methods. The proximate composition of pumpkin seed products,wheat flour and bread was determined using the following AOAC [17] meth-ods: Moisture content (No. 14.004), crude protein (No. 2.057), crude fat (No.7.056) and total ash (No. 14.006).

For mineral assays, samples were digested with concentrated sulfuric acidand percholoric acid. Sodium and potassium were measured by flame photo-metry (Corning 400). Calcium, zinc, manganese, iron, and copper were es-timated using an AASI atomic absorption spectrophotometry (Perkin-ElmerInstrument Model 2380).

Amino acids were determined using a Beckman amino acid analyzer (Mo-del 118/119CL) according to the method described by Moore & Stein [18].Flour hydrolysis was performed in the presence of 6 N HCL at 110 ◦C for 22h in a nitrogen atmosphere. Sulfur containing amino acids were determinedafter performic acid oxidation. Tryptophan was chemically determined by themethod of Miller [19].

In vitro digestibility and biological value. In vitro protein digestibility wasdetermined as described by Salgo et al. [20] by measuring the change inthe sample solution pH after incubation at 37 ◦C with a trypsin-pancreatinenzyme mixture for 10 min. In vitro protein digestibility was determinedin triplicate. Chemical scores of the amino acids were calculated using theFAO/WHO [21] reference pattern.

Statistical analysis. Physical properties of dough, sensory properties ofbread and chemical composition of bread were analyzed using StatisticalAnalysis System [22]. Significant differences between treatments were de-termined at the 5% level.

Results and discussion

Physical properties of the dough. The physical properties of control (wheatflour) and pumpkin seed blends to result in protein levels of 15, 17, 19 and21% are shown in Table 2. Water absorption was increased significantly (p ≤0.05) due to the addition of pumpkin seed products at all protein levels exceptfor raw pumpkin seed meal at a 15% protein content. In general, wheat flourfortified with pumpkin protein isolate had the highest water absorption atall levels of blending followed by fermented, germinated, autoclaved, androasted pumpkin seed meals, and pumpkin protein concentrate. The increase

371

Table 2. Farinograph characteristics of wheat-flour pumpkin product blends∗

Product Protein Water Development Stability Softeninglevel % absorption time(dry weight (%) (min) (min) (BU)basis)

Control 12.5 61.20 1.80 4.20 90Raw pumpkin seed meal

15 61.80 3.10 2.90 10017 62.60 3.20 2.80 12019 63.10 2.90 2.40 13521 63.50 2.90 2.30 155

Roasted pumpkin seed meal15 62.60 3.20 2.70 11517 63.50 3.20 2.60 12019 64.10 2.80 2.40 13021 64.50 2.80 2.20 140

Autoclaved pumpkin seed meal15 62.30 3.40 2.70 11017 63.10 3.30 2.50 11519 63.10 3.00 2.30 12521 64.10 2.80 2.20 135

Germinated pumpkin seed meal15 62.90 3.20 3.40 10017 63.80 3.00 3.30 11019 64.6 2.90 3.20 12021 65.00 2.90 3.20 130

Fermented pumpkin seed meal15 63.30 3.00 3.80 10017 64.10 2.80 3.50 11519 64.70 2.80 3.40 12021 65.40 2.70 3.40 125

Pumpkin seed protein concentrate15 62.20 3.20 3.60 10017 62.90 3.10 3.60 11019 63.60 2.90 3.40 11521 64.00 2.60 3.40 120

Pumpkin seed protein isolate15 64.50 3.00 3.90 9517 65.70 2.70 3.80 10019 66.40 2.50 3.70 10521 67.30 2.50 3.70 110

LSD 1.03 0.44 0.35 2.80

∗ Means of three determinations.

372

in water absorption was due to the high water hydration capacity of pumpkinseed products, especially pumpkin protein isolate. Generally, these resultsagree well with those reported by Rasco et al. [23], Gonzalez-Galan et al. [5]and Yue et al. [6], who found that water absorption increased substantially, by5–15 percent, with the addition of native sunflower protein concentrate andisolate to wheat flour. Also these results are in accordance with those of El-Adawy [7] and Mansour et al. [8]. From Table 2, one can see that all wheatflour-pumpkin seed blends required a significantly (p ≤ 0.05) higher doughdevelopment time than the control. However, dough development time wasdecreased as pumpkin seed product levels increased but was still higher thanfor wheat flour. Generally, the increment in dough development time may beattributed to the differences in physicochemical properties of pumpkin seedproducts and that of wheat flour as previously detected by Morad et al. [24]and El-Adawy [7].

Dough stability time, as a major index of dough strength, was decreased bythe addition of pumpkin seed products to wheat flour, except pumpkin proteinisolate at the 15% protein level of substitution (Table 2). These results are inaccordance with those results of Anjum et al. [25] and Yue et al. [6], whoindicated that the high level of replacement of sunflower protein concentrateand isolate may have been responsible for decreasing dough stability time.Roasted and autoclaved pumpkin seed meals had the lowest values for doughstability and the highest values for dough softening, which could be attributedto the heat treatment and its effect on protein denaturation. In contrast, pump-kin seed protein isolate had the lowest amount of softening compared withthe others which paralleled dough stability. Table 2 data shows also that thereplacement with pumpkin seed products increased the weakening of doughsignificantly (p ≤ 0.05). Dough softening was increased with the increase inprotein level. The dough weakening could have been due to; (a) the presenceof sulphhydryl groups in pumpkin seed products which lead to dough soften-ing [26]; (b) the decrease in wheat gluten because of the dilution effect and(c) the competition between proteins of pumpkin products and wheat flourfor water [27]. These results also agree well with those of Ranga Rao andcoworkers [28], who reported that supplementation of wheat flour with 5–20% wheat germ, on weight basis, decreased water absorption, stability andsoftening of bread dough They also agree with those of Mansour et al. [8].

Bread characteristics. Sensory properties of bread fortified with pumpkinseed products are presented in Table 3. There were no significant (p > 0.05)differences between the control (wheat flour) bread and breads fortified withraw, roasted and autoclaved pumpkin meals (up to 17% protein level), ger-minated and fermented pumpkin meals and pumpkin protein concentrate (up

373

Table 3. Sensory properties∗ of pumpkin seed product-wheat flour breads

Product Protein Crust Crumb Crumb Flavor∗∗ Overall Loaflevel % color∗∗ color∗∗ texture∗∗ quality∗∗ volume∗∗∗(dry weight (cm3)basis)

Control 12.5 4.40 4.50 4.40 4.30 4.40 240Raw pumpkin seed meal

15 4.20 4.40 4.10 4.20 4.20 21717 3.80 4.10 3.60 3.80 3.80 18819 3.20 3.70 3.10 3.50 3.40 16821 2.80 3.20 2.60 3.00 3.00 158

Roasted pumpkin seed meal15 4.30 4.40 4.40 4.30 4.40 22217 4.10 4.20 4.10 4.10 4.10 19519 3.60 3.80 3.60 3.70 3.70 18521 3.20 3.30 3.10 3.40 3.30 169

Autoclaved pumpkin seed meal15 4.30 4.40 4.40 4.30 4.40 22517 4.10 4.20 4.10 4.20 4.20 20019 3.70 3.90 3.70 3.80 3.70 19021 3.20 3.50 3.30 3.40 3.40 175

Germinated pumpkin seed meal15 4.30 4.40 4.40 4.30 4.40 23017 4.20 4.30 4.20 4.20 4.20 21519 3.80 4.00 3.90 3.90 3.90 20521 3.20 3.70 3.70 3.60 3.50 197

Fermented pumpkin seed meal15 4.40 4.50 4.40 4.30 4.40 23217 4.20 4.30 4.30 4.20 4.30 22019 3.90 4.10 4.00 4.00 4.00 20721 3.20 3.90 3.70 3.70 3.60 202

Pumpkin seed protein concentrate15 4.30 4.40 4.40 4.30 4.40 22717 4.10 4.20 4.10 4.10 4.10 21819 3.40 3.90 3.80 3.70 3.60 20321 3.00 3.40 3.50 3.40 3.30 193

Pumpkin seed protein isolate15 4.40 4.50 4.40 4.30 4.40 23617 4.40 4.40 4.40 4.30 4.40 22819 4.20 4.30 4.20 4.20 4.20 22321 3.90 4.20 4.10 4.10 4.10 206

LSD 0.30 0.28 0.29 0.25 0.28 2.17

∗ Sensory attributes were: 5 = excellent, 4 = good, 3 = satisfactory, 2 = fair, 1 = poor.∗∗ Means of five panelist scores.∗∗∗ Means of three determinations.

374

Fig

ure

2.L

oaf

volu

me

ofpu

mpk

inpr

oduc

t–w

heat

flou

rbl

end

brea

ds.

375

to 19% protein level) and pumpkin protein isolate (up to 21% protein level)with regard to crust and crumb color, flavor and overall acceptability. Man-sour et al. [8] indicated that there were no differences in taste and odor amongbreads containing up to 18% pumpkin seed protein concentrate or canolaprotein isolate or up to 20% pumpkin meal, pumpkin protein isolate or canolaprotein concentrate. Also, breads containing 22% pumpkin meal, pumpkinprotein isolate or canola protein concentrate were not significantly differentin odor from each other or the control bread. The results of loaf volume inFigure 2 and Table 3 show that the volume decreased with increasing levelof substitution. The loaf volume of the control was significantly (p ≤ 0.05)higher than those baked with raw, roasted pumpkin meals (all protein levels),autoclaved pumpkin meal (17, 19 and 21% protein levels), pumpkin proteinconcentrate (19 and 21% protein levels), germinated pumpkin meal (19 and21% protein levels), fermented pumpkin meal (19 and 21% protein levels)and pumpkin protein isolate (21% protein level). However, there was no sig-nificant depression in loaf volume for breads containing pumpkin proteinisolate up to a 21 percent protein level. Also, the same trend was observedfor breads containing pumpkin protein concentrate, fermented pumpkin meal,and germinated pumpkin meal at the 19 percent protein level, and autoclaved,roasted and raw pumpkin meals at the 17 percent protein level. These resultsare much better than those reported by El-Adawy [7], who found that oil-seeds had a varying effect on dough mixing and loaf volume characteristics,and heating enhanced the bread making characteristics of cotton seed andsunflower proteins but was detrimental to these properties in peanut and ses-ame proteins. Also Hansmeyer and coworkers [29] and Yue and coworkers [6]reported a detrimental effect on loaf quality with the addition of succinylatedsunflower protein concentrate and isolate to breads. Flour blends contain-ing 5% native sunflower protein concentrate and isolate produced acceptablebreads, but the quality of the breads deteriorated at 10–15% of the samefractions. The current results agree well with those of Mansour et al. [8], whofound that addition of canola and pumpkin protein concentrate and isolategreater than 18 to 22% yielded dense, compact and unacceptable breads, andbetter than those with Talley et al. [30], who found that 17% and 30% sub-stitution of sunflower meal in wheat flour produced dense, compact loaves;3% enrichment resulted in an attractive loaf. From the results in the currentstudy, one can conclude that there were no significant (p > 0.05) differencesbetween control and raw, roasted and autoclaved pumpkin meal breads up tothe 17% protein level; germinated, fermented pumpkin meals and pumpkinprotein concentrate up to a 19% protein level and pumpkin protein isolate upto a 21% protein level. Therefore, the rest of this study was conducted usingbreads containing those protein levels.

376

Tabl

e4.

Pro

xim

ate

com

posi

tion

ofbr

ead

fort

ified

with

pum

pkin

seed

prod

ucts

(dry

wei

ghtb

asis

)∗

Pro

duct

Moi

stur

eC

rude

prot

ein

Cru

defa

tA

shC

arbo

hydr

ate4

(%)

(%)

(%)

(%)

(%)

Con

trol

9.60

a13

.50a

2.55

b1.

53a

72.8

2d

Raw

pum

pkin

seed

mea

l110

.31a

17.2

0b2.

72b

1.85

c67

.92c

Roa

sted

pum

pkin

seed

mea

l19.

82a

17.3

1b2.

64b

1.75

bc68

.48c

Aut

ocla

ved

pum

pkin

seed

mea

l19.

63a

17.1

1b2.

69b

1.79

bc68

.78c

Ger

min

ated

pum

pkin

seed

mea

l210

.11a

19.0

2c2.

41b

1.81

c66

.65b

Fer

men

ted

pum

pkin

seed

mea

l29.

93a

19.2

1c2.

89b

1.61

ab66

.36b

Pum

pkin

seed

prot

ein

conc

entr

ate2

9.84

a19

.13c

2.75

b1.

93c

66.3

5b

Pum

pkin

seed

prot

ein

isol

ate3

10.1

1a21

.19d

2.11

a1.

61ab

64.9

8a

LS

D0.

710.

950.

490.

191.

12

a,b,

c,d

Mea

nsin

the

sam

eco

lum

nw

ith

diff

eren

tlet

ters

are

sign

ifica

ntly

diff

eren

t(p

<0.

05).

117

%pr

otei

nle

vel,

219

%pr

otei

nle

vel,

321

%pr

otei

nle

vel,

4ca

lcul

ated

bydi

ffer

ence

.∗ M

eans

ofth

ree

dete

rmin

atio

ns.

377

Chemical composition of bread. The changes in chemical composition ofbreads fortified with pumpkin seed products at the 17% protein level of raw,roasted, and autoclaved pumpkin meal; 19% protein of germinated, fermen-ted pumpkin meal and pumpkin protein concentrate, and 21% protein levelof pumpkin protein isolate are shown in Table 4. Addition of pumpkin seedproducts to wheat flour increased the protein content significantly. No signi-ficant (p > 0.05) differences in crude fat were observed between control andpumpkin seed product breads, with the exception of pumpkin protein isol-ate, which had the lowest value among the products. There were significant(p ≤ 0.05) differences between the wheat flour and pumpkin seed productsubstituted breads in ash content, except fermented pumpkin seed meal andpumpkin seed protein isolate, which were the same (1.61%) but lower thanthe others. Pumpkin protein isolate bread had the lowest carbohydrate content(65%), which could have been due to the multiple extractions with alkali andacid. Longe et al. [31] reported that the composition of defatted pumpkinseed was 69.7% crude protein, 8.2% crude fiber, 6.5% fat, 9.3% ash and6.3% carbohydrate (dry matter basis). These results are in accordance withthe results of Khan et al. [2], Hansmyer et al. [29], Rasco et al. [32], Salamaet al. [33], El-Adawy [7] and Mansour et al. [8].

Mineral contents of breads. Data presented in Table 5 show the mineralcontents of breads fortified with pumpkin seed products. The results revealedthat there was a marked increase in minerals in the final products with theexception of sodium, which was lower in almost all pumpkin supplementedbreads. Pumpkin protein isolate breads had approximately one and half timesthe sodium content of the control. Copper was double the control. Fermen-ted meal and pumpkin protein isolate breads had the highest contents ofCa++ (140 and 145 mg/100 g, respectively), while roasted and autoclavedpumpkin meal breads had double the content of K+ relative to the control.Roasted pumpkin meal bread had approximately two and half times moreMg++ compared with the control.

Pumpkin protein isolate bread had lower amounts of minerals than thoseof other pumpkin seed product and control breads, except Na and Cu. Theseresults are in accordance with Mansour et al. [12–14], El-Adawy [7] andMansour et al. [8].

Amino acids profiles of breads. Data presented in Table 6 show the aminoacid composition of the breads. The addition of pumpkin seed products towheat flour appeared to increase the concentration of most of the essentialamino acids (isolucine, lysine, cystine, methionine, threonine, tryptophan andvaline), compared to the control. For lysine, the increase was 200–280% com-pared to the control. Comparison of the amino acid composition of pumpkin

378

Tabl

e5.

Min

eral

cont

ento

fbr

ead

fort

ified

wit

hpu

mpk

inse

edpr

oduc

ts(d

ryw

eigh

tbas

is)∗

Pro

duct

Na

Ca

KP

Mg

Cu

Zn

Fe

Mn

(mg/

100

g)

Con

trol

485.

6098

.30

74.1

085

.30

60.6

00.

373.

101.

901.

20

Raw

pum

pkin

seed

mea

l145

7.50

128.

5010

0.70

139.

8011

1.30

0.52

3.20

3.60

2.20

Roa

sted

pum

pkin

seed

mea

l141

3.50

124.

2013

5.20

154.

0014

5.20

0.41

3.20

3.80

1.90

Aut

ocla

ved

pum

pkin

seed

mea

l142

9.20

136.

2014

2.00

161.

3012

2.60

0.63

2.80

3.60

1.70

Ger

min

ated

pum

pkin

seed

mea

l249

8.30

125.

9012

5.40

180.

5012

5.80

0.61

3.70

3.90

2.40

Fer

men

ted

pum

pkin

seed

mea

l243

2.30

140.

2092

.80

120.

9011

5.60

0.42

3.00

4.10

2.20

Pum

pkin

seed

prot

ein

conc

entr

ate2

433.

1012

0.70

90.0

013

6.70

81.1

00.

513.

303.

602.

20

Pum

pkin

seed

prot

ein

isol

ate3

746.

9014

5.30

78.2

010

9.20

60.4

00.

721.

502.

500.

73

117

%pr

otei

nle

vel,

219

%pr

otei

nle

vel,

321

%pr

otei

nle

vel.

∗ Ave

rage

oftw

ode

term

inat

ions

.

379

Tabl

e6.

Am

ino

acid

com

posi

tion

ofbr

ead

fort

ified

with

pum

pkin

seed

prod

ucts

(g/1

6g

nitr

ogen

)

Am

ino

acid

Con

trol

Raw

Roa

sted

Aut

ocla

ved

Ger

min

ate

Fer

men

ted

Pum

pkin

Pum

pkin

FAO

/WH

Opu

mpk

inpu

mpk

inpu

mpk

inpu

mpk

inpu

mpk

inse

edpr

otei

nse

edpr

otei

n(1

973)

seed

mea

l1se

edm

eal1

seed

mea

l1se

edm

eal2

seed

mea

l2co

ncen

trat

e2is

olat

e3

Isol

euci

ne3.

813.

903.

994.

223.

904.

353.

303.

704.

00L

euci

ne7.

937.

297.

717.

546.

397.

967.

307.

807.

00L

ysin

e2.

024.

824.

454.

194.

155.

133.

905.

205.

50C

ysti

ne1.

921.

982.

081.

781.

221.

951.

901.

90–

Met

hion

ine

0.90

1.60

1.77

1.55

1.77

1.82

1.30

1.20

–To

tals

ulfu

ram

ino

acid

2.82

3.58

3.45

3.33

2.99

3.77

3.20

3.10

3.50

Tyro

sine

4.92

4.01

3.39

3.87

3.61

4.33

5.40

4.90

–P

heny

lala

nine

5.51

5.07

5.19

5.13

4.98

5.39

5.10

5.50

–To

tala

rom

atic

amin

oac

id10

.43

9.08

8.38

9.00

8.59

9.62

10.5

010

.40

6.00

Thr

eoni

ne3.

973.

723.

954.

083.

514.

174.

204.

604.

00T

rypt

opha

n0.

590.

830.

650.

730.

620.

900.

901.

001.

00V

alin

e3.

714.

544.

784.

854.

794.

923.

203.

805.

00To

tale

ssen

ital

amin

oac

id35

.28

37.7

637

.56

37.9

434

.94

40.8

236

.50

39.6

036

.00

His

tidi

ne3.

334.

253.

874.

424.

464.

233.

403.

60–

Arg

inin

e4.

155.

245.

525.

395.

654.

675.

106.

50–

Asp

arti

cac

id5.

626.

316.

476.

837.

216.

097.

307.

40–

Glu

tam

icac

id24

.57

20.2

520

.61

19.8

621

.05

17.7

721

.90

18.4

0–

Ser

ine

6.03

6.11

6.37

5.76

5.98

6.22

5.70

6.10

–P

roli

ne14

.38

12.5

112

.50

11.3

512

.78

11.9

011

.30

9.90

–G

lyci

ne3.

343.

473.

213.

873.

043.

914.

704.

30–

Ala

nine

3.30

4.10

3.89

4.58

4.89

4.40

4.10

4.20

–To

taln

on-e

ssen

tial

amin

oac

ids

64.7

262

.24

62.4

462

.06

65.0

659

.18

63.5

060

.40

–

117

%pr

otei

nle

vel,

219

%pr

otei

nle

vel,

321

%pr

otei

nle

vel.

380

seed breads showed that pumpkin seed products contained similar or highertotal essential amino acids levels than the FAO/WHO [21] pattern, exceptfor a few modest deficiencies. The deficiency of these amino acids was notthe result of pumpkin seed product addition. Pumpkin protein isolate andfermented pumpkin meal breads had the highest contents of lysine and totalessential amino acids. This apparent increase may have been due to the loss ofsome protein fractions during their preparation (multiple soaking and mixingwith water) which contain plenty of non-essential amino acids. Fermentedpumpkin meal bread had a higher content of total sulfur amino acids than theothers and the standard; this may have been due to the fermentation process.Hansmeyer et al. [29] reported that the lysine content of breads increasedtwo times with the addition of wheat bran protein concentrate to wheat flour.Carlson et al. [34] reported that supplementation of the wheat flour with 10–20% tomato seed flour increased lysine content by 40–69% in breads. Also,these results agree well with Salama et al. [33], El-Adawy [7] and Mansouret al. [8].

In vitro digestibility and biological value of breads. In vitro protein digest-ibilities are given in Table 7. Pumpkin seed product breads had significantly(p ≤ 0.05) higher protein digestibility than the control bread. Digestibility ofbread containing pumpkin protein isolate and fermented pumpkin meal wasmuch better than the others. These results agree well with those reported byGonzalez Agramon & Serna-Saldivar [35], who found that soybean isolatefortified tortillas had higher digestibility than 100% wheat flour and soybeanmeal fortified tortillas. The better digestibility of fermented meal may be at-tributed to the easier attack of the proteolytic enzymes due to the fermentationprocess. Also the digestibility of both the concentrate and isolate was betterthan that of the meal which may have been due to the denaturation of proteinduring preparation. Sathe et al. [36] reported that heat denaturation of lupinseed protein increased sensitivity to proteolytic attack. In general, the additionof pumpkin seed products to bread improved the protein digestibility. Book-walter et al. [37] reported that fortification of sorghum with 15% soy mealincreased the digestibility from 75 to 85%. Therefore, the low protein digest-ibility of wheat could be improved by mixing with highly digestible proteinsuch as that from pumpkin seed products. Also, addition of the pumpkin seedproducts to wheat flour improved the chemical score (CS) better than thecontrol. Maciejewicz-Rys & Hanczakowski [38] reported that supplementa-tion of wheat flour with 33% leaf protein concentrate, from the green matterof barley, improved the chemical score from 42 to 50%. The same trend wasobserved by El-Adawy [7, 39] who showed that supplementation of wheatwith detoxified apricot kernel and sesame seed products improved the chem-

381

Tabl

e7.

Invi

tro

prot

ein

dige

stib

ility

and

biol

ogic

alva

lue

ofbr

ead

fort

ified

with

pum

pkin

seed

prod

ucts

(dry

wei

ghtb

asis

)

Pro

duct

Invi

tro

Che

mic

alF

irst

Sec

ond

Thi

rdP

ER

∗∗B

V∗∗

∗pr

otei

nsc

ore

lim

itin

gli

mit

ing

lim

itin

gdi

gest

ibil

ity∗

(CS

)%

amin

oac

idam

ino

acid

amin

oac

id

Con

trol

72.5

1a37

.25

Lys

ine

Try

ptop

han

Val

ine

2.24

073

.440

(37.

25)

60.2

975

.64

Raw

pum

pkin

seed

mea

l176

.22b

97.3

5T

rypt

opha

nL

ysin

eV

alin

e2.

050

71.5

10(9

7.35

)83

.43

86.6

2R

oast

edpu

mpk

inse

edm

eal1

76.7

3b62

.48

Try

ptop

han

Lys

ine

Val

ine

2.24

073

.530

(62.

48)

77.4

491

.69

Aut

ocla

ved

pum

pkin

seed

mea

l178

.45bc

69.4

6T

rypt

opha

nL

ysin

eTo

tals

ulfu

r2.

220

73.2

80(6

9.46

)72

.18

amin

oac

ids

90.9

4G

erm

inat

edpu

mpk

inse

edm

eal2

79.3

4bc64

.06

Try

ptop

han

Lys

ine

Tota

lsul

fur

1.62

967

.060

(64.

06)

77.6

3am

ino

acid

s88

.22

Fer

men

ted

pum

pkin

seed

mea

l282

.56c

79.6

9T

rypt

opha

nL

ysin

eV

alin

e2.

386

75.0

30(7

9.69

)82

.24

86.9

4P

umpk

inse

edpr

otei

nco

ncen

trat

e280

.63bc

63.1

6V

alin

eL

ysin

eIs

oluc

ine

2.11

472

.160

(63.

16)

69.8

481

.45

Pum

pkin

seed

prot

ein

isol

ate3

82.7

2c69

.66

Val

ine

Tota

lsul

fur

Isol

ucin

e2.

408

75.2

51(6

9.66

)am

ino

acid

s84

.82

81.3

6

a−c∗

Mea

nsin

the

sam

eco

lum

nfo

llow

edw

ith

the

sam

ele

tter

are

nots

igni

fican

tly

diff

eren

t(p

>0.

05)

usin

gD

unca

n’s

Mul

tipl

eR

ange

Test

.M

eans

ofth

ree

dete

rmin

atio

ns.

117

%pr

otei

nle

vel,

219

%pr

otei

nle

vel,

321

%pr

otei

nle

vel,

4ca

lcul

ated

bydi

ffer

ence

.∗∗

PE

R=

–0.6

84+

0.45

6L

euci

ne–

0.04

7P

roli

ne[4

1].

∗∗∗ B

V=

49.9

+10

.53

PE

R[4

2].

382

ical score and essential amino acids. Mansour et al. [8] found that wheat flourfortified with pumpkin seed and canola protein isolate and concentrate en-hanced amino acid indices; PER and BV were similar to the control. Also, thesame trend was observed for the pumpkin seed product breads investigated,except for pumpkin protein isolate and fermented pumpkin meal, which hadthe highest PER and BV values compared to the other products and control(2.408 and 75.251, and 2.386 and 75.030 respectively).

Lysine was the first limiting amino acid for the control bread; it was thesecond for the pumpkin seed products. Total sulfur amino acids were thesecond limiting amino acids for pumpkin protein isolate. Tryprophan wasthe first limiting amino acids for the pumpkin seed products, except pumpkinprotein concentrate and isolate with valine as the first limiting amino acid.These results differ from those in fluted pumpkin reported by Sharma etal. [40] and Longe et al. [31]. They found that the sulfur-containing aminoacids were the first limiting amino acids, while lysine and threonine werethe second limiting amino acids. This difference may have been due to theinterspecies variation.

General conclusion

Pumpkin seed products increased the water absorption, dough developmenttime and softening but decreased the stability and loaf volume. Pumpkinprotein isolate and fermented pumpkin meal had the best results among thepumpkin seed products compared to the control.

Also increasing the protein level beyond a certain point resulted in unac-ceptable bread quality, therefore there was an upper limit of protein supple-mentation which was 17% for raw, roasted and autoclaved pumpkin meal,19% for germinated, fermented and pumpkin protein concentrate and 21%for pumpkin protein isolate.

Pumpkin protein isolate, fermented pumpkin meal and pumpkin proteinconcentrate produced the best overall acceptability.

The ash contents and also the macro and micro mineral contents of breadsfortified with pumpkin seed products, especially Ca, K, P, Mg, Cu, Fe and Mnwere increased compared with the control and other oilseeds such as peanuts,sunflowers and rapeseed meal.

Increasing the lysine, total sulfur amino acids, chemical score, total es-sential amino acids, crude protein, protein digestibility, crude fat, ash andmineral content qualify pumpkin seed products as a good source of proteinand nutrients for fortification of baked products, especially bread. Pumpkinseed protein isolate, fermented pumpkin seed meal and pumpkin seed proteinconcentrate showed the best results among the pumpkin seed products.

383

References1. Rooney LW, Gustafson CB, Clark SP, Cater CM (1972) Comparison of the baking

properties of several oilseed flours. J Food Sci 37: 15–19.2. Khan MN, Rhee KC, Rooney LW, Cater CM (1975) Bread baking properties of aqueous

processed peanut protein concentrate. J Food Sci 40: 580–583.3. Sosulski FW, Cadden AM (1982) Composition and physiological properties of several

sources of dietary fiber. J Food Sci 47: 1472–1474.4. Cadden AM, Sosulski FW, Olson JP (1983) Physiological responses of rats to high fiber

bread diets containing several sources of hulls or bran. J Food Sci 48: 1151.5. Gonzalez-Galan A, Wang SH, Segarbier VC, Moraes MAC (1991) Sensory and nutri-

tional properties of cookies based on wheat-rice-soybean flours baked in a microwaveoven. J Food Sci 56: 1699–1701.

6. Yue P, Hettiarachchy N, D’Appolonia BL (1991) Native and Succinylated sunflowerprotein use in bread making. J Food Sci 56: 992–998.

7. El-Adawy TA (1995) Effect of sesame seed proteins supplementation on the nutritional,physical, chemical and sensory properties of wheat flour bread. Plant Food Hum Nutr48: 311–326.

8. Mansour EH, Dworschak E, Pollhamer ZS, Gergely A, Hovari J (1999) Pumpkin andcanola seed proteins and bread quality. Acta Alimentaria 28: 59–70.

9. Lazos SE (1986) Nutritional, fatty acid and oil characteristics of pumpkin and melonseeds. J Food Sci 51: 1382–1383.

10. Nwokolo E, Sim SJ (1987) Nutritional assessment of defatted oil meals of melon (Colo-cynthis Citrullus L.) and fluted pumpkin (Telfaria occidentalis Hook) by chick assay. JSci Food Agric 38: 237–246.

11. Mansour EH, Peredi J, Dworschak E (1992) Preparation and functional properties ofrapeseed protein products. Acta Alimentaria 21: 294–305.

12. Mansour EH, Dworschak E, Peredi J, Lugasi A (1993) Evaluation of pumpkin seed(Cucurbita pepo, Kakai 35) as a new source of protein. Acta Alimentaria 22: 3–13.

13. Mansour EH, Dworschak E, Lugasi A, Barna E, Gergely A (1993) Nutritive value ofpumpkin (Cucurbita pepo, Kakai 35) seed products. J Sci Food Agric 61: 73–76.

14. Mansour EH, Dworschak E, Lugasi A, Gaal O, Barna E, Gergely A (1993) Effect ofprocessing on the antinutritive factors and nutritive value of rapeseed products. FoodChem 47: 247–252.

15. AACC (1983) Approved Methods of The American Association of Cereal Chemists, 8thedn. St. Paul, MN: AACC.

16. Pollhamer ZS (1981) Oven increment determination. Acta Agron Hung 30: 1–17.17. AOAC (1980) Official Methods of Analysis, 13th edn. Washington, DC: The Association

of Official Analytical Chemists.18. Moore S, Stein WH (1963) Chromatographic determination of amino acids by the use

of automatic recording equipment. In: Colowick SP, Kaplan NO (eds), Methods inEnzymology, Vol. 6. New York: Academic Press, pp 860.

19. Miller EL (1967) Determination of tryptophan content in feeding stuffs with particularreference to cereal. J Sci Food Agric 18: 381–386.

20. Salgó A, Granzler K, Jecsai J (1984) Simple enzymatic methods for predicition of plantprotein digestibility. In: Lasztity R, Hidvegi M (eds), Proceedings of the InternationalAssociation of Cereal Chemistry Symposium. Budapest, Hungary: Akademiai Kiadó,pp 311–321.

21. FAO/WHO (1973) Energy and protein requirements. Report of FAO Nutritional MeetingSeries No. 52. Rome: FAO.

384

22. SAS (1985) SAS User Guide: Statistics Version, 5th edn. Cary, NC: SAS Institute Inc.23. Rasco BA, Rubenthaler G, Borhan M, Dong FM (1990) Baking properties of beard and

cookies incorporating distillers or brewer’s grain from wheat or barley. J Food Sci 55:425–429.

24. Morad MM, El-Magoli SB, Afifi SA (1980) Macaroni supplemented with lupine anddefatted soybean flour. J Food Sci 45: 404–405.

25. Anjum FM, Ali A, Chaudhry NM (1991) Fatty acids, mineral composition and functional(bread and chapati) properties of high protein and high lysine barley lines. J Sci FoodAgric 55: 511–519.

26. El-Farra AA, Ismail AA, Kourshid AM (1981) Liquid whey milk and its effect on wheatflour dough and pasta properties. Egypt J Food Sci 9: 49–57.

27. Deshpande SS, Rangnekor PD, Sathe SK, Salunkhe DK (1983) functional properties ofwheat-bean composite flours. J Food Sci 48: 1659–1663.

28. Ranga Rao GCP, Haridas RAO, Kumar GV, Shurpalekar SR (1980) Utilization of wheatgerm in the perpetration of bread and biscuits. J Food Technol 17: 171–175.

29. Hansmeyer WA, Satterlee LD, Mattern PJ (1976) Characterization of products from wetfractionation of wheat bran. J Food Sci 41: 505–508.

30. Talley LJ, Brummett BJ, Burns EE (1972) Sunflower food products. Texas A & M Univ,The Texas Agricultural Experiment Station, MP 1026.

31. Longes GO, Farinu OG, Fetuga LB (1983) Nutritional value of the fluted pumpkin(Telfaria occidentalis). J Agric Food Chem 31: 989–992.

32. Rasco BA, Hashisaka AE, Dong FM, Einstein MA (1989) Sensory evaluation of bakedgoods incorporating different levels of distiller’s dried grains with solubles from softwhite winter wheat. J Food Sci 54: 337–342.

33. Salama NA, Abd El-Latef AR, Shouk AA, Alian AM (1992) Effect of some improverson the nutritional components and in vitro digestibility of Egyptian balady bread. EgyptJ Food Sci 20: 135–146.

34. Carlson BL, Knorr D, Watkins TR (1981) Influence of tomato seed addition on thequality of wheat flour breads. J Food Sci 46: 1029–1031.

35. Gonzalez-Agramon M, Serna-Saldivar SO (1988) Effect of defatted soybean and soy-bean isolate fortification on the nutritional, physical, chemical and sensory properties ofwheat flour tortillas. J Food Sci 53: 793–797.

36. Sathe TB, Desphands SS, Salunkhe DK (1982) Functional properties of lupin seed(Lupinus mutabilis). Proteins and protein concentrates. J Food Sci 47: 492–497.

37. Bookwalter GN, Kirleis AW, Mertz ET (1987) In vitro digestibility of protein milledsorghum and other processed cereals with and without soy fortification. J Agric FoodChem 35: 347–351.

38. MacieJewicz-Rys J, Hanczakowski P (1990) Improvement of nutritive value of cerealsby leaf protein supplementation. J Sci Food Agric 50: 99–104.

39. El-Adawy TA (1992) Chemical, technological studies and characterization of apricotkernel proteins, PhD Thesis, Faculty of Agriculture, Menofiya University, Shibin El-Kom, Egypt.

40. Sharma PB, Lai BM, Madaan TR, Chatterjee SR (1986) Studies on the nutritional qualityof some Cucurbit kernel proteins. J Sci Food Agric 37: 418–420.

41. Alsmeyer RH, Cunningham AE, Happich ML (1974) Equations predict PER from aminoacid analysis. Food Tech 28 (7): 34.

42. Michel HH, Block J (1946) The correlation of the amino acid composition of proteinwith their nutritive value. Nutr Abstr Rev 16: 249.