Ejemplo_diseño_PV

-

Upload

abel-duarte-rodriguez -

Category

Documents

-

view

221 -

download

0

Transcript of Ejemplo_diseño_PV

-

8/4/2019 Ejemplo_diseo_PV

1/21

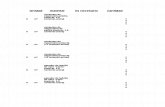

Pressure Vessel Engineering, Ltd.120 Randall Dr. Waterloo, Ontario N2V 1C6

Date Printed: 10/30/2008

CUSTOMERXYZ Vessel Corp

123 Anytown

Ontario, Canada H0H 0H0

VESSEL LOCATIONXYZ Vessel Corp

123 AnytownOntario, Canada H0H 0H0

VESSEL DESCRIPTIONSampe Vessel 2

Vessel designed with Advanced Pressure Vessel, Version: 9.2.3Vessel is ASME Code Stamped

Job No: PVE-Sample 2Vessel Number: 1

NAMEPLATE INFORMATIONVessel MAWP: 200.00 PSI at 300 F

MDMT: -20 F at 200.00 PSISerial Number(s): PVE Ssample Vessel - 2

National Board Number(s): __________________________________

Year Built: 2007Radiography: NONE

Postweld Heat Treated: NONEConstruction Type: W

Signatures

P.Eng:_______________________________________________________________ Date: ____/____/____

Laurence Brundrett

Mechanical Technologist:_______________________________________________________________ Date: ____/____/____Milorad Gavric

-

8/4/2019 Ejemplo_diseo_PV

2/21

Pressure Vessel Engineering, Ltd.120 Randall Dr. Waterloo, Ontario N2V 1C6

Date Printed: 10/30/2008

-

8/4/2019 Ejemplo_diseo_PV

3/21

Pressure Vessel Engineering, Ltd.Shell 1

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Number: 1 Mark Number: S1

Date Printed: 10/30/2008

Cylindrical Shell Design Information

Design Pressure: 200.00 PSI Design Temperature: 300 F

Static Head: 0.00 PSI Long. Joint Efficiency: 85 %Shell Material: SA-106 Gr B Factor B Chart: CS-2

Material Stress (hot): 17100 PSIShell Length: 36.0000 in. Material Stress (cold): 17100 PSI

Compressive Stress: 17247 PSI

Corrosion Allowance: 0.0000 in. Actual Circumferential Stress: 4478 PSIExternal Corrosion Allowance: 0.0000 in. Actual Longitudinal Stress: 2555 PSI

Outside Diameter (new): 12.7500 in.Outside Diameter (corroded): 12.7500 in. Specific Gravity: 1.00

Shell Surface Area: 10.01 Sq. Ft. Weight of Fluid: 147.26 lb.Shell Estimated Volume: 17.63 Gal. Total Flooded Shell Weight: 295.79 lb.

Circ. Joint Efficiency: 70 % Shell Weight: 148.53 lb.

Minimum Design Metal Temperature Data

Min. Temperature Curve: B Pressure at MDMT: 200.00 PSI

UCS-66(b) reduction: No Minimum Design Metal Temperature: -20 FUCS-68(c) reduction: No Computed Minimum Temperature: -20 F

Design Thickness Calculations

Longitudinal Stress Calculations per Paragraph UG-27(c)(2)

t =PR

2SE + 0.4P=

200.00 * 6.0000

2 * 17100 * 0.70 + 0.4 * 200.00

= Greater Of (0.0500(Calculated), 0.0625(Minimum Allowed)) + 0.0000 (corrosion) + 0.0000 (ext. corrosion) + 0.0469 (12 1/2% for pipe)

= minimum of 0.1094

Circumferential Stress Calculations per Appendix 1-1(a)(1)

t =PRo

SE + 0.4P=

200.00 * 6.3750

17100 * 0.85 + 0.4 * 200.00= 0.0873 + 0.0000 (corrosion) + 0.0000 (ext. corrosion) + 0.0469 (12 1/2% for pipe)

= minimum of 0.1342

External loads do not control design.

Pipe Selected: Size = 12 in., Schedule = STD, Diameter = 12.7500 in., Wall = 0.3750 in.

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 1 of 18

-

8/4/2019 Ejemplo_diseo_PV

4/21

Pressure Vessel Engineering, Ltd.Head Left

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Number: 1 Mark Number: H1

Date Printed: 10/30/2008

Ellipsoidal Head Design Information

Design Pressure: 200.00 PSI Design Temperature: 300 FStatic Head: 0.00 PSI Joint Efficiency: 85 %

Head Material: SA-234 Gr WPB Factor B Chart: CS-2Material Stress (hot): 17100 PSI

Corrosion Allowance: 0.0000 in. Material Stress (cold): 17100 PSI

External Corrosion Allowance: 0.0000 in. Actual Head Stress: 4360 PSIHead Location: Left Straight Flange : 2.8000 in.

Outside Diameter : 12.7500 in. Head Depth (ho) : 3.3750 in.12.5 % pipe undertolerance: 0.0469 in.

K = [2 + (D/2h) ] : 1.00

Head Surface Area: 1.92 Sq. Ft. Specific Gravity: 1.00

Head Estimated Volume: 2.35 Gal. Weight of Fluid: 19.60 lb.Head Weight: 29.27 lb. Total Flooded Head Weight: 48.87 lb.

Minimum Design Metal Temperature Data

Min. Temperature Curve: B Pressure at MDMT: 200.00 PSIUCS-66(b) reduction: No Minimum Design Metal Temperature: -20 FUCS-68(c) reduction: No Computed Minimum Temperature: -20 F

Design Thickness Calculations

Design Thickness Calculations per Appendix 1-4(c)

t =PDoK

2SE + 2P(K - 0.1)=

200.00 * 12.7500 * 1.00

2 * 17100 * 0.85 + 2 * 200.00 * (1.00 - 0.1)

= 0.0867 + 0.0000 (corrosion) + 0.0000 (ext. corrosion) + 0.0469(12.5 %) = minimum of 0.1336

Nominal Head Thickness Selected = 0.3750 in.Minimum Thickness after forming, ts (uncorroded) = 0.3281 in.

Pipe CapSize: 12 Schedule: STD

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 2 of 18

-

8/4/2019 Ejemplo_diseo_PV

5/21

Pressure Vessel Engineering, Ltd.Head Right

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Number: 2 Mark Number: H2

Date Printed: 10/30/2008

Ellipsoidal Head Design Information

Design Pressure: 200.00 PSI Design Temperature: 300 FStatic Head: 0.00 PSI Joint Efficiency: 85 %

Head Material: SA-234 Gr WPB Factor B Chart: CS-2

Material Stress (hot): 17100 PSICorrosion Allowance: 0.0000 in. Material Stress (cold): 17100 PSI

External Corrosion Allowance: 0.0000 in. Actual Head Stress: 4360 PSIHead Location: Right Straight Flange : 2.8000 in.

Outside Diameter : 12.7500 in. Head Depth (ho) : 3.3750 in.

12.5 % pipe undertolerance: 0.0469 in.K = [2 + (D/2h) ] : 1.00

Head Surface Area: 1.92 Sq. Ft. Specific Gravity: 1.00

Head Estimated Volume: 2.35 Gal. Weight of Fluid: 19.60 lb.Head Weight: 29.27 lb. Total Flooded Head Weight: 48.87 lb.

Minimum Design Metal Temperature Data

Min. Temperature Curve: B Pressure at MDMT: 200.00 PSIUCS-66(b) reduction: No Minimum Design Metal Temperature: -20 FUCS-68(c) reduction: No Computed Minimum Temperature: -20 F

Design Thickness Calculations

Design Thickness Calculations per Appendix 1-4(c)

t =PDoK

2SE + 2P(K - 0.1)=

200.00 * 12.7500 * 1.00

2 * 17100 * 0.85 + 2 * 200.00 * (1.00 - 0.1)

= 0.0867 + 0.0000 (corrosion) + 0.0000 (ext. corrosion) + 0.0469(12.5 %) = minimum of 0.1336

Nominal Head Thickness Selected = 0.3750 in.Minimum Thickness after forming, ts (uncorroded) = 0.3281 in.

Pipe CapSize: 12 Schedule: STD

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 3 of 18

-

8/4/2019 Ejemplo_diseo_PV

6/21

Pressure Vessel Engineering, Ltd.Threaded Coupling - 2"

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Number: 1 Mark Number: N2ID Number: N2

Date Printed: 10/30/2008

Nozzle Design Information

Design Pressure: 200.00 PSI Design Temperature: 300 FStatic Head: 0.00 PSI Nozzle Efficiency (E): 100 %

Nozzle Material: SA-105 Joint Efficiency (E1): 1.00Factor B Chart: CS-2

External Projection: 1.0000 in. Allowable Stress at Design Temperature (Sn): 20000 PSI

Internal Projection: 0.0000 in. Allowable Stress at Ambient Temperature: 20000 PSIInside Corrosion Allowance: 0.0000 in. Correction Factor (F): 1.00

External Corrosion Allowance: 0.0000 in. Passes through a Category A Joint: NoNozzle ID (new): 2.4060 in. Nozzle Wall Thickness(new): 0.3125 in.

Nozzle ID (corroded): 2.4060 in. Nozzle Wall Thickness(corroded): 0.3125 in.Outer "h" Limit: 0.7813 in. Upper Weld Leg Size(Weld 41): 0.3130 in.

Internal "h" Limit: 0.7813 in. Internal Weld Leg Size(Weld 43): 0.0000 in.OD, Limit of Reinforcement: 4.8120 in. Outside Groove Weld Depth: 0.3750 in.

Minimum Design Metal Temperature

Min. Temp. Curve: B Pressure at MDMT: 200.00 PSIUCS-66(b) reduction: No Minimum Design Metal Temperature: -20 FUCS-68(c) reduction: No Computed Minimum Temperature: -20 F

Host Component: Head 1 - Head Left

Material: SA-234 Gr WPB Head wall thickness(new): 0.3750 in.

Material Stress(Sv): 17100 PSI Head wall thickness - 12% for pipe: 0.3281 in.

Nozzle Detail Information

Upper Weld Leg Size(Weld 41): 0.3130

Nozzle Wall Thickness(tn): 0.3125

Outside Groove Weld Depth: 0.3750

Nozzle passes through the vessel, attached by a groove weld.

Nozzle is adequate for UG-45 requirements.Opening is adequately reinforced for Internal Pressure.

Reinforcement calculations are not required per UG-36(c)(3)(a)See Uw-14 for exceptions.Weld Strength Paths are adequate.

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 4 of 18

-

8/4/2019 Ejemplo_diseo_PV

7/21

Pressure Vessel Engineering, Ltd.Threaded Coupling - 2"

Job No: PVE-Sample 2 Vessel Number: 1Number: 1 Mark Number: N2

ID Number: N2

Date Printed: 10/30/2008

Required Head Thickness per Paragraph UG-37(a)

tr =

P K1 Do

(2SE + 0.8P) =

200.00 * 0.9000 * 12.7500

(2 * 17100 * 1 + 0.8 * 200.00) = 0.0668

Nozzle Required Thickness Calculations

Required Nozzle Thickness for Internal Pressure per Paragraph UG-37(a)

trn =PRn

SE - 0.6P=

200.00 * 1.2030

20000 * 1 - 0.6 * 200.00= 0.0121

Strength Reduction Factors

fr1 = SnSv

= 2000017100

= 1.0000 fr2 = SnSv

= 2000017100

= 1.0000 fr3 = SnSv

= 2000017100

= 1.0000

UG-45 Thickness Calculations

Nozzle Thickness for Pressure Loading (plus corrosion) per Paragraph UG-45(a)

t =PRn

SE - 0.6P+ Ca + ext. Ca =

200.00 * 1.2030

20000 * 1.00 - 0.6 * 200.00+ 0.0000 + 0.0000 = 0.0121

Nozzle Thickness for Internal Pressure (plus corrosion) per Paragraph UG-45(b)(1)

t =

P K Do

(2SE + 2P(K - 0.1)) + Ca + ext. Ca =

200.00 * 1.0000 * 12.7500

(2 * 17100 * 1 + 2 * 200.00 * (1.0000 - 0.1)) + 0.0000 + 0.0000 = 0.0738

Minimum Thickness of Standard Wall Pipe (plus corrosion) per Paragraph UG-45(b)(4)t = minimum thickness of standard wall pipe + Ca + ext. Ca = 0.1890

Nozzle Minimum Thickness per Paragraph UG-45(b)t = Smallest of UG-45(b)(1) or UG-45(b)(4) = 0.0738

Wall thickness = tn = 0.3125 is greater than or equal to UG-45 value of 0.0738

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 5 of 18

-

8/4/2019 Ejemplo_diseo_PV

8/21

Pressure Vessel Engineering, Ltd.Threaded Coupling - 2"

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Number: 2 Mark Number: N3ID Number: N3

Date Printed: 10/30/2008

Nozzle Design Information

Design Pressure: 200.00 PSI Design Temperature: 300 FStatic Head: 0.00 PSI Nozzle Efficiency (E): 100 %

Nozzle Material: SA-105 Joint Efficiency (E1): 1.00Factor B Chart: CS-2

External Projection: 1.0000 in. Allowable Stress at Design Temperature (Sn): 20000 PSIInternal Projection: 0.0000 in. Allowable Stress at Ambient Temperature: 20000 PSI

Inside Corrosion Allowance: 0.0000 in. Correction Factor (F): 1.00External Corrosion Allowance: 0.0000 in. Passes through a Category A Joint: No

Nozzle ID (new): 2.4060 in. Nozzle Wall Thickness(new): 0.3125 in.Nozzle ID (corroded): 2.4060 in. Nozzle Wall Thickness(corroded): 0.3125 in.

Outer "h" Limit: 0.7813 in. Upper Weld Leg Size(Weld 41): 0.3130 in.

Internal "h" Limit: 0.7813 in. Internal Weld Leg Size(Weld 43): 0.0000 in.OD, Limit of Reinforcement: 4.8120 in. Outside Groove Weld Depth: 0.3750 in.

Minimum Design Metal Temperature

Min. Temp. Curve: B Pressure at MDMT: 200.00 PSIUCS-66(b) reduction: Yes Minimum Design Metal Temperature: -20 FUCS-68(c) reduction: No Computed Minimum Temperature: -155 F

Host Component: Head 2 - Head Right

Material: SA-234 Gr WPB Head wall thickness(new): 0.3750 in.Material Stress(Sv): 17100 PSI Head wall thickness - 12% for pipe: 0.3281 in.

Nozzle Detail Information

Upper Weld Leg Size(Weld 41): 0.3130

Nozzle Wall Thickness(tn): 0.3125

Outside Groove Weld Depth: 0.3750

Nozzle passes through the vessel, attached by a groove weld.

Nozzle is adequate for UG-45 requirements.Opening is adequately reinforced for Internal Pressure.

Reinforcement calculations are not required per UG-36(c)(3)(a)See Uw-14 for exceptions.Weld Strength Paths are adequate.

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 6 of 18

-

8/4/2019 Ejemplo_diseo_PV

9/21

Pressure Vessel Engineering, Ltd.Threaded Coupling - 2"

Job No: PVE-Sample 2 Vessel Number: 1Number: 2 Mark Number: N3

ID Number: N3

Date Printed: 10/30/2008

Required Head Thickness per Paragraph UG-37(a)

tr =

P K1 Do

(2SE + 0.8P) =

200.00 * 0.9000 * 12.7500

(2 * 17100 * 1 + 0.8 * 200.00) = 0.0668

Nozzle Required Thickness Calculations

Required Nozzle Thickness for Internal Pressure per Paragraph UG-37(a)

trn =PRn

SE - 0.6P=

200.00 * 1.2030

20000 * 1 - 0.6 * 200.00= 0.0121

Strength Reduction Factors

fr1 = SnSv

= 2000017100

= 1.0000 fr2 = SnSv

= 2000017100

= 1.0000 fr3 = SnSv

= 2000017100

= 1.0000

UG-45 Thickness Calculations

Nozzle Thickness for Pressure Loading (plus corrosion) per Paragraph UG-45(a)

t =PRn

SE - 0.6P+ Ca + ext. Ca =

200.00 * 1.2030

20000 * 1.00 - 0.6 * 200.00+ 0.0000 + 0.0000 = 0.0121

Nozzle Thickness for Internal Pressure (plus corrosion) per Paragraph UG-45(b)(1)

t =

P K Do

(2SE + 2P(K - 0.1)) + Ca + ext. Ca =

200.00 * 1.0000 * 12.7500

(2 * 17100 * 1 + 2 * 200.00 * (1.0000 - 0.1)) + 0.0000 + 0.0000 = 0.0738

Minimum Thickness of Standard Wall Pipe (plus corrosion) per Paragraph UG-45(b)(4)t = minimum thickness of standard wall pipe + Ca + ext. Ca = 0.1890

Nozzle Minimum Thickness per Paragraph UG-45(b)t = Smallest of UG-45(b)(1) or UG-45(b)(4) = 0.0738

Wall thickness = tn = 0.3125 is greater than or equal to UG-45 value of 0.0738

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 7 of 18

-

8/4/2019 Ejemplo_diseo_PV

10/21

Pressure Vessel Engineering, Ltd.Threaded Coupling - 0.5"

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Number: 3 Mark Number: N4ID Number: N4

Date Printed: 10/30/2008

Nozzle Design Information

Design Pressure: 200.00 PSI Design Temperature: 300 FStatic Head: 0.00 PSI Nozzle Efficiency (E): 100 %

Nozzle Material: SA-105 Joint Efficiency (E1): 1.00Factor B Chart: CS-2

External Projection: 0.5000 in. Allowable Stress at Design Temperature (Sn): 20000 PSIInternal Projection: 0.0000 in. Allowable Stress at Ambient Temperature: 20000 PSI

Inside Corrosion Allowance: 0.0000 in. Correction Factor (F): 1.00External Corrosion Allowance: 0.0000 in. Passes through a Category A Joint: No

Nozzle ID (new): 0.8550 in. Nozzle Wall Thickness(new): 0.1425 in.Nozzle ID (corroded): 0.8550 in. Nozzle Wall Thickness(corroded): 0.1425 in.

Outer "h" Limit: 0.3563 in. Upper Weld Leg Size(Weld 41): 0.2500 in.

Internal "h" Limit: 0.3563 in. Internal Weld Leg Size(Weld 43): 0.0000 in.OD, Limit of Reinforcement: 1.7962 in. Outside Groove Weld Depth: 0.3750 in.

Minimum Design Metal Temperature

Min. Temp. Curve: B Pressure at MDMT: 200.00 PSIUCS-66(b) reduction: Yes Minimum Design Metal Temperature: -20 FUCS-68(c) reduction: No Computed Minimum Temperature: -155 F

Host Component: Shell 1 - Shell 1

Material: SA-106 Gr B Shell wall thickness(new): 0.3750 in.Material Stress(Sv): 17100 PSI Shell wall thickness - 12% for pipe (corroded): 0.3281 in.

Nozzle Detail Information

Upper Weld Leg Size(Weld 41): 0.2500

Nozzle Wall Thickness(tn): 0.1425

Outside Groove Weld Depth: 0.3750

Nozzle passes through the vessel, attached by a groove weld.

Nozzle is adequate for UG-45 requirements.Opening is adequately reinforced for Internal Pressure.

Reinforcement calculations are not required per UG-36(c)(3)(a)See Uw-14 for exceptions.Weld Strength Paths are adequate.

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 8 of 18

-

8/4/2019 Ejemplo_diseo_PV

11/21

Pressure Vessel Engineering, Ltd.Threaded Coupling - 0.5"

Job No: PVE-Sample 2 Vessel Number: 1Number: 3 Mark Number: N4

ID Number: N4

Date Printed: 10/30/2008

Required Shell Thickness per Paragraph UG-37(a)

tr =

PRo

SE + 0.4P =

200.00 * 6.3750

17100 * 1 + 0.4 * 200.00 = 0.0742

Nozzle Required Thickness Calculations

Required Nozzle Thickness for Internal Pressure per Paragraph UG-37(a)

trn =PRn

SE - 0.6P=

200.00 * 0.4275

20000 * 1 - 0.6 * 200.00= 0.0043

Strength Reduction Factors

fr1 = SnSv

= 2000017100

= 1.0000 fr2 = SnSv

= 2000017100

= 1.0000 fr3 = SnSv

= 2000017100

= 1.0000

UG-45 Thickness Calculations

Nozzle Thickness for Pressure Loading (plus corrosion) per Paragraph UG-45(a)

t =PRn

SE - 0.6P+ Ca + ext. Ca =

200.00 * 0.4275

20000 * 1.00 - 0.6 * 200.00+ 0.0000 + 0.0000 = 0.0043

Nozzle Thickness for Internal Pressure (plus corrosion) per Paragraph UG-45(b)(1)

t =

PRo

SE + 0.4P + Ca + ext. Ca =

200.00 * 6.3750

17100 * 1 + 0.4 * 200.00 + 0.0000 + 0.0000 = 0.0742

Minimum Thickness of Standard Wall Pipe (plus corrosion) per Paragraph UG-45(b)(4)t = minimum thickness of standard wall pipe + Ca + ext. Ca = 0.1164

Nozzle Minimum Thickness per Paragraph UG-45(b)t = Smallest of UG-45(b)(1) or UG-45(b)(4) = 0.0742

Wall thickness = tn = 0.1425 is greater than or equal to UG-45 value of 0.0742

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 9 of 18

-

8/4/2019 Ejemplo_diseo_PV

12/21

Pressure Vessel Engineering, Ltd.Pipe -4"

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Number: 4 Mark Number: N1ID Number: N1

Date Printed: 10/30/2008

Nozzle Design Information

Design Pressure: 200.00 PSI Design Temperature: 300 FStatic Head: 0.00 PSI Nozzle Efficiency (E): 100 %

Nozzle Material: SA-106 Gr B Joint Efficiency (E1): 1.00Factor B Chart: CS-2

External Projection: 7.7500 in. Allowable Stress at Design Temperature (Sn): 17100 PSIInternal Projection: 1.1250 in. Allowable Stress at Ambient Temperature: 17100 PSI

Inside Corrosion Allowance: 0.0000 in. Correction Factor (F): 1.00External Corrosion Allowance: 0.0000 in. Passes through a Category A Joint: No

Nozzle Pipe Size: 4 Nozzle Pipe Schedule: 40Nozzle ID (new): 4.0260 in. Nozzle Wall Thickness(new): 0.2370 in.

Nozzle ID (corroded): 4.0260 in. Nozzle Wall Thickness(corroded): 0.2370 in.

Outer "h" Limit: 0.5925 in. Upper Weld Leg Size(Weld 41): 0.2500 in.Internal "h" Limit: 0.5925 in. Internal Weld Leg Size(Weld 43): 0.2500 in.

OD, Limit of Reinforcement: 8.0520 in. Outside Groove Weld Depth: 0.3750 in.

Minimum Design Metal Temperature

Min. Temp. Curve: B Pressure at MDMT: 200.00 PSIUCS-66(b) reduction: No Minimum Design Metal Temperature: -20 F

UCS-68(c) reduction: No Computed Minimum Temperature: -20 F

Host Component: Shell 1 - Shell 1

Material: SA-106 Gr B Shell wall thickness(new): 0.3750 in.Material Stress(Sv): 17100 PSI Shell wall thickness - 12% for pipe (corroded): 0.3281 in.

Nozzle Detail Information

Upper Weld Leg Size(Weld 41): 0.2500

Internal Weld Leg Size(Weld 43): 0.2500

Nozzle Wall Thickness(tn): 0.2370

Outside Groove Weld Depth: 0.3750

Nozzle passes through the vessel, attached by a groove weld.Pipe Size: 4 Schedule: 40

Nozzle is adequate for UG-45 requirements.Opening is adequately reinforced for Internal Pressure.

Weld Strength Paths are adequate.

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 10 of 18

-

8/4/2019 Ejemplo_diseo_PV

13/21

Pressure Vessel Engineering, Ltd.Pipe -4"

Job No: PVE-Sample 2 Vessel Number: 1Number: 4 Mark Number: N1

ID Number: N1

Date Printed: 10/30/2008

Required Shell Thickness per Paragraph UG-37(a)

tr =

PRo

SE + 0.4P =

200.00 * 6.3750

17100 * 1 + 0.4 * 200.00 = 0.0742

Nozzle Required Thickness Calculations

Required Nozzle Thickness for Internal Pressure per Paragraph UG-37(a)

trn =PRn

SE - 0.6P=

200.00 * 2.0130

17100 * 1 - 0.6 * 200.00= 0.0237

Strength Reduction Factors

fr1 = SnSv

= 1710017100

= 1.0000 fr2 = SnSv

= 1710017100

= 1.0000 fr3 = SnSv

= 1710017100

= 1.0000

UG-45 Thickness Calculations

Nozzle Thickness for Pressure Loading (plus corrosion) per Paragraph UG-45(a)

t =PRn

SE - 0.6P+ Ca + ext. Ca =

200.00 * 2.0130

17100 * 1.00 - 0.6 * 200.00+ 0.0000 + 0.0000 = 0.0237

Nozzle Thickness for Internal Pressure (plus corrosion) per Paragraph UG-45(b)(1)

t =

PRo

SE + 0.4P + Ca + ext. Ca =

200.00 * 6.3750

17100 * 1 + 0.4 * 200.00 + 0.0000 + 0.0000 = 0.0742

Minimum Thickness of Standard Wall Pipe (plus corrosion) per Paragraph UG-45(b)(4)t = minimum thickness of standard wall pipe + Ca + ext. Ca = 0.2074

Nozzle Minimum Thickness per Paragraph UG-45(b)t = Smallest of UG-45(b)(1) or UG-45(b)(4) = 0.0742

Wall thickness = tn * 0.875(pipe) = 0.2074 is greater than or equal to UG-45 value of 0.0742

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 11 of 18

-

8/4/2019 Ejemplo_diseo_PV

14/21

Pressure Vessel Engineering, Ltd.Pipe -4"

Job No: PVE-Sample 2 Vessel Number: 1Number: 4 Mark Number: N1

ID Number: N1

Date Printed: 10/30/2008

Nozzle Reinforcement Calculations

Area Required for Internal Pressure

A = d tr F + 2 tn tr F (1 - fr1) = (4.0260 * 0.0742 * 1.00) + (2 * 0.2370 * 0.0742 * 1.00 * (1 - 1.0000)) = 0.2987 sq. Area Available - Internal Pressure

A1 Formula 1 = d(E1 t - F tr) - 2tn(E1 t - F tr)(1 - fr1) =4.0260 * (1.00 * 0.3281 - 1.00 * 0.0742) - 2 * 0.2370 * (1.00 * 0.3281 - 1.00 * 0.0742) * (1 - 1.0000) = 1.0222sq. in.

A1 Formula 2= 2(t + tn)(E1 t - F tr) - 2tn(E1 t - F tr)(1 - fr1) =2 * (0.3281 + 0.2370)(1.00 * 0.3281 - 1.00 * 0.0742) - 2 * 0.2370 * (1.00 * 0.3281 - 1.00 * 0.0742) * (1 - 1.0000)

= 0.2870sq. in.A1 = Larger value of A1 Formula 1 and A1 Formula 2 = 1.0222 sq.

A2 Formula 1 = 5(tn - trn) fr2 t = 5(0.2370 - 0.0237) * 1.0000 * 0.3281 = 0.3499sq. in.A2 Formula 2= 5(tn - trn) fr2 tn = 5(0.2370 - 0.0237) * 1.0000 * 0.2370 = 0.2528sq. in.A2 = Smaller value of A2 Formula 1 and A2 Formula 2 = 0.2528 sq.

A3 = Smaller value of the following :

5 * t * ti * fr2 = 5 * 0.3281 * 0.2370 * 1.0000 = 0.3888 sq. in.5 * ti * ti * fr2 = 5 * 0.2370 * 0.2370 * 1.0000 = 0.2808 sq. in.2 * h * ti * fr2 = 2 * 1.1250 * 0.2370 * 1.0000= 0.5333 sq. in.

= 0.2808 sq.

A41 = (leg) * fr2 = (0.2500) * 1.0000 = 0.0625 sq.

A43 = (leg) * fr2 = (0.2500) * 1.0000 = 0.0625 sq.

Area Available (Internal Pressure) = A1 + A2 + A3 + A41 + A43 = 1.6808 sq. in., which is greater than A (0.2987)

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 12 of 18

-

8/4/2019 Ejemplo_diseo_PV

15/21

Pressure Vessel Engineering, Ltd.Saddle 1

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Number: 1 Mark Number: SDL1

Date Printed: 10/30/2008

Saddle Design Information

Design Temperature: 300 F Support Type: Type II

Material: SA-516 Gr 70 Stiffener Quantity: 2Condition: Material Stress (hot): 20000 PSI

Length (d): 11.0000 in. Material Stress (cold): 20000 PSITop Width (b'): 2.0000 in. Yield Strength: 33600 PSI

Bottom Width (bb'): 2.0000 in. Density: 0.2830 lb/in.^3Outside Stiffener Thickness (tso): 0.3750 in. Web Plate Thickness (tw): 0.3750 in.

Inside Stiffener Thickness (tsi): 0.2500 in. Vessel Centerline Height (h): 12.0000 in.Saddle Angle of contact (): 120.0 Elevation above grade (g): 0.0000 in.

Dist. from saddle centerline to tang. line (A): 5.0000 in.Support Design Condition: Shell unstiffened (A/R > 1/2)

Base Plate Information

Design Temperature: 300 F Ultimate 28 Day Concrete Strength: 3000.00 PSIMaterial: SA-516 Gr 70 Yield Strength: 33600 PSI

Condition: Length (m): 13.0418 in.Width (bb): 3.0000 in. Thickness (tb): 0.3750 in.

Anchor Bolt Information

Material: SA-193 Gr B16

-

8/4/2019 Ejemplo_diseo_PV

16/21

Pressure Vessel Engineering, Ltd.Sampe Vessel 2

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Date Printed: 10/30/2008

ASME Flange Design Information

Host Description Type Size Material ASME Material MAP(in.) Class Group (PSI)

Pipe -4" ASME Flange 1 Slip-On 4 SA-105 150 1.1 230.00

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 14 of 18

-

8/4/2019 Ejemplo_diseo_PV

17/21

Pressure Vessel Engineering, Ltd.Customer: XYZ Vessel Corp

Job No: PVE-Sample 2 Vessel Number: 1

Date Printed: 10/30/2008

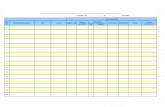

Zick Analysis

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 15 of 18

-

8/4/2019 Ejemplo_diseo_PV

18/21

Pressure Vessel Engineering, Ltd.Customer: XYZ Vessel Corp

Job No: PVE-Sample 2 Vessel Number: 1

Date Printed: 10/30/2008

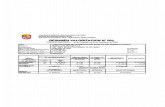

MDMT Report by ComponentsDesign MDMT is -20 F

Component Material Curve Pressure MDMT

Shell 1 SA-106 Gr B B 200.00 PSI -20 FThreaded Coupling - 0.5" SA-105 B 200.00 PSI -155 FPipe -4" SA-106 Gr B B 200.00 PSI -20 F

Head Left SA-234 Gr WPB B 200.00 PSI -20 FThreaded Coupling - 2" SA-105 B 200.00 PSI -20 F

Head Right SA-234 Gr WPB B 200.00 PSI -20 FThreaded Coupling - 2" SA-105 B 200.00 PSI -155 F

Component with highest MDMT: Shell 1.

Computed MDMT = -20 F

The required design MDMT of -20 F has been met or exceeded for the calculated MDMT values.

ANSI Flanges Are Not Included in MDMT Calculations.

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 16 of 18

-

8/4/2019 Ejemplo_diseo_PV

19/21

Pressure Vessel Engineering, Ltd.Sampe Vessel 2

Customer: XYZ Vessel CorpJob No: PVE-Sample 2 Vessel Number: 1

Date Printed: 10/30/2008

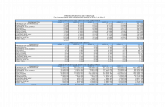

MAWP Report by Components

Vessel Component Vessel

MAWP MAWP MAWPDesign Static New & Cold Hot & Corroded Hot & Corroded

Component Pressure Head UG-98(a) UG-98(b) UG-98(a)Shell 1 200.00 PSI 0.00 PSI 647.66 PSI 647.66 PSI 647.66 PSI

Threaded Coupling - 0.5" 200.00 PSI 0.00 PSI 898.71 PSI 898.71 PSI 898.71 PSIPipe -4" 200.00 PSI 0.00 PSI 647.66 PSI 647.66 PSI 647.66 PSI

ASME Flange Class: 150 Gr:1.1 0.00 PSI 285.00 PSI 230.00 PSI 230.00 PSIHead Left 200.00 PSI 0.00 PSI 784.40 PSI 784.40 PSI 784.40 PSI

Threaded Coupling - 2" 200.00 PSI 0.00 PSI 975.63 PSI 975.63 PSI 975.63 PSIHead Right 200.00 PSI 0.00 PSI 784.40 PSI 784.40 PSI 784.40 PSI

Threaded Coupling - 2" 200.00 PSI 0.00 PSI 975.63 PSI 975.63 PSI 975.63 PSI

NC = Not Calculated Inc = Incomplete

Summary

Component with the lowest vessel MAWP(New & Cold) : ASME Flange Class: 150 Gr:1.1

The lowest vessel MAWP(New & Cold) : 285.00 P

Component with the lowest vessel MAWP(Hot & Corroded) : ASME Flange Class: 150 Gr:1.1

The lowest vessel MAWP(Hot & Corroded) : 230.00 P

Pressures are exclusive of any external loads.

Flange pressures listed here do not consider external loadings

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 17 of 18

-

8/4/2019 Ejemplo_diseo_PV

20/21

Pressure Vessel Engineering, Ltd.Customer: XYZ Vessel Corp

Job No: PVE-Sample 2 Vessel Number: 1

Date Printed: 10/30/2008

Summary Information

Dry Weight Flooded WeightShell 148.53 lb. 295.79 lb.Head 58.53 lb. 97.74 lb.

Nozzle 10.50 lb. 10.50 lb.ANSI Flange 13.00 lb. 13.00 lb.

_________________ _________________Totals 230.56 lb. 417.03 lb.

Volume

Shell 17.63 Gal.Head 4.70 Gal.Nozzle 0.60 Gal.

_________________Totals 22.93 Gal.

Area

Shell 10.01 Sq. Ft.Head 3.83 Sq. Ft.Nozzle 1.34 Sq. Ft.

_________________Totals 15.19 Sq. Ft.

Hydrostatic Test Information (UG-99)Gauge at Top

Component with controlling ratio is : Shell 1Component with controlling pressure is : Shell 1

Calculated Test Pressure = P * 1.3 *Cold Stress

Hot Stress= 200.00 * 1.3 *

17100

17100= 260.00 P

Advanced Pressure Vessel version: 9.2.3 Computer Engineering, Inc. Section VIII, Division 1, 2004 Edition, 2006 AddenPage 18 of 18

-

8/4/2019 Ejemplo_diseo_PV

21/21

Table of Contents

Shell 1 1

Head Left 2

Head Right 3

Threaded Coupling - 2" 4

Threaded Coupling - 2" 6

Threaded Coupling - 0.5" 8

Pipe -4" 10

Saddle Information 13

ASME Flanges 14

Zick Information - Saddle: Saddle 1 15

MDMT Summary 16

MAWP Summary 17

Summary Information 18