CORROSION, DIMENSIONAL STABILITY AND ......The precipitate size composition dependence shows that...

Transcript of CORROSION, DIMENSIONAL STABILITY AND ......The precipitate size composition dependence shows that...

V.N. Shishov, M.M. Peregud, A.Yu. Shevyakov, V.A. Markelov, A.V.Nikulina, V.V. Novikov

(JSC “VNIINM Bochvar”, Moscow, Russia)

I.N. Volkova, A.E. Novoselov, G.P. Kobylyansky, A.V.Obukhov

(JSC "NIIAR", Dimitrovgrad, Russia)

CORROSION, DIMENSIONAL STABILITY AND

MICROSTRUCTURE OF VVER-1000 E635 ALLOY FA

COMPONENTS AT BURNUPS UP TO 72 MWDAY/KGU

17th International Symposium on Zirconium in the Nuclear Industry

(India, Hyderabad, 3 - 7 February 2013)

2

Introduction

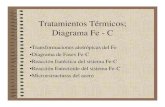

• Corrosion, hydrogenation, dimensional changes (growth, creep) limit the fuel assemblies (FA) operation time and cycles. The problem is being solved in VVER-1000 via FA, FA-2, FA-2M, FAA designs and materials used since 1995. The components at FAA skeleton (guide thimbles-GT, central tube-CT, rigid angles-RA) and fuel rod claddings are produced from irradiation resistant E635(Zr-1% Nb-1.2% Sn-0.35% Fe) alloy (spacer grids-SG - from E110 (Zr-1% Nb) and feature high strength and high resistance to shape changes and corrosion.

• E635 items operate in more than 687 FA-2, 2500 FAA of VVER-1000. The use of E635 as an assembly skeleton material gives significant improvement to FA performance (the bending has been decreased by more than 4 times).

Objective

3

Objective of this study are to define:

- relationship of corrosion and hydrogenation characteristics;

- tensile properties;

- structural-phase state

of E635 components with heat flux (claddings)

and without heat flux (GT, RA, CT, welded joints).

E635 is used as the material for the FAA VVER-1000

components in the Kalinin NPP, 6-year operation, maximum

burn-up ~ 72 MW·d/kgU

Content

4

- Materials and operating conditions

- Dimensional stability

- Oxidation

- Hydriding

- Tensile properties

- TEM Investigations

- Conclusion

5

Materials and Operating Conditions The skeleton - 6 rigid angles (RA) at frames, 18 guide thimbles (GT), central tube (CT), and

fuel claddings – all E635;

15 spacer grids (SG) –E110.

GT3 and RA1 are located near the fuel rod 21

with a maximum burn-up of 72.4 MW·d/ kgU.

GT9 and RA4 - near the fuel rod 302

with a minimum burn-up 54.3 MW·d / kgU.

6

10

20

40

60

70

80

600 1200 1800 2400 3000 3600

Height , mm

Bu

rn-u

p М

W*d

/kg

U

rod 21 rod 302

30

rod 138

50

Estimates of the cladding and GT temperature height distribution are shown. The temperature of the GT, CT and

RA corresponds to the coolant temperature and ranged from 286 to 320 º C from the FAA bottom to the top.

Fuel cladding temperature at the "metal-oxide" surface could be about 350 º С.

Burn-up height distribution

Height distribution of cladding (■) and GT (♦) temperature

Dimensional stability

7

The measurements indicate a high dimensional stability of E635 components. The bending maximum

value is 5.9 mm; it is lower than for E110 cladding after 6 years performance. Guide tubes elongation

is ~ 0.12 %, which is almost two times smaller than that of CT. Elongation of rods (due to irradiation

creep), increasing with the fuel burn-up, about 2 times higher than the SG and rigid angles

elongation. In accordance with the concepts of irradiation creep of anisotropic materials under the

external coolant pressure, the diameter of fuel rod cladding decreases, while their length increases.

Elongation of rods with E635 claddings -▲

is less than that of E110 alloy - □"Fuel-cladding" gap of the fuel rods is reduced

with burn-up increasing (54.3, 67.2 and 72.4

MW·d/ kgU). A small gap exists in cold state

even in rods with a maximum fuel burn-up.

0

10

20

30

40

50

50 55 60 65 70 75

Burn-up, МW*day/kgU

Gap, μ

m

Characterization of oxide thickness

8

The cladding surface over the entire FAA height has uniform grey-white color and becomes lighter

with increasing axial elevation. The oxide film peeling is not observed. The specimens located in

the direction of the maximal burn-up gradient at the minimal, average and maximal burn-ups (up

to 72 MW·d/kg U) at four height levels with different neutron fluence and temperature were taken

for investigation.

0

10

20

30

40

50

60

80

0 500 1000 1500 2000 2500 3000 3500 4000

Height, mm

CTGT3GT9rod 138

70

oxid

e t

hic

kn

ess, μ

m

0

10

20

30

40

50

60

70

80

90

100

0 500 1000 1500 2000 2500 3000 3500 4000Коордиината, мм

То

лщ

ин

а о

кси

дн

ой

плен

ки

, м

км

Неразрушающие исследования, ориентация 0

Неразрушающие исследования, ориентация 180

Разрушающие исследования, металлография

The oxide film thickness on the outer cladding, GT and CT surface increases with elevation up

to ~ 3000 mm, with its subsequent decrease. The minimum oxide thickness is observed at the gas

collector level (above~ 3500 mm). There is a good agreement between the oxide film thickness

determined by eddy current and metallography.

rod 21 cladding rod 138, GT3, GT9 and CT

9

The cladding oxide film fracture surface: presence of cracks and layers

54.3 MW·d / kgU; 67.2 MW·d / kgU 72.4 MW·d/ kgU

Hydrides in the fuel rod claddings (3000 mm)Hydrides of tangential orientation are distributed over the cladding cross section: in the rod 21 with

maximum burn-up hydrides are concentrated along the outer surface. Weight fraction of hydrogen in

the claddings does not exceed 0.03% and varies in height, correlating with the oxide film thickness.

10

The cladding oxide film fracture surface: presence of cracks and layers

54.3 MW·d / kgU; 67.2 MW·d / kgU 72.4 MW·d/ kgU

Hydrides in the fuel rod claddings (3000 mm)Hydrides of tangential orientation are distributed over the cladding cross section: in the rod 21 with

maximum burn-up hydrides are concentrated along the outer surface. Weight fraction of hydrogen in

the claddings does not exceed 0.03% and varies in height, correlating with the oxide film thickness.

11

Time,years Тtest., оС В, МPа 0,2, МPа о, % Р, %

320 600-700 525-630 7,4-11 2,8-3,9

380 445-465 400-410 14-21 3,2-3,9

620 720-790 680-760 4,9-9,1 2,0-3,8

380 530-580 500-540 8-15 2,4-4,2

The tensile strength (в), yield strength (0,2), total (о) and uniform (р) elongation of

E635 components were determined by the test of ring tensile specimens at the room and

work (350 ° C) temperatures.

Tensile properties

Tensile properties of E635 alloy cladding in the transverse direction

Investigation of the fracture surface of ring samples after tensile tests showed mostly

ductile fracture mode. Near the inner surface brittle transcrystalline fracture mode

dominates. Cracks can be formed at locations of tangentially oriented hydrides .

12

TEM studies of precipitates in fuel rod 21 cladding

FeZrNb

Thin foils and extraction carbon replicas were studied in an electron microscope JEM-2000FXII using

an energy dispersive X-ray spectrometer EDAX (structure-phase state, chemical composition).

gas collector level

level 3000 mm

SPPs are uniformly distributed over grains, composition depends on their size. The smaller the

particle, the less iron it contains. Former Laves phase SPPs are transformed into polycrystalline β-Nb

particles. In a gas collector SPPs contain stacking faults -the absence of transformation.

13

Dislocation structure is characterized by the presence of dislocation loops a-type

arranged in rows along the direction [01.0], and c-dislocations near particles.

Fuel rod 21 cladding dislocation structure and

radiation-induced precipitates (RIP)

Level 3000 mm : - a-loops; - c-dislocations

Gas collector level :c-dislocations were not detected and a-loops alignment is weak

RIPs

14

At the gas collector level - 3500 mm

c-dislocations are practically absent,

most of Fe is in Laves phase;

SPP crystal lattice remained unchanged

TEM structure of guide thimbles, central tube and angles

near the maximum burn-up of fuel rods

at level 3000 mm: a-loops alignment c-dislocations

The precipitate size composition dependence shows that SPPs in GT,CT and RA contain less Fe compared to

the cladding. Fe content is very low even in large particles at the level 3000 mm and lower.

The matrix composition dependence (Nb, Fe) on height

coordinates in rods 21, 302, guide thimbles, central tube

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0 1000 3000 4000

rod 21

2000

Nb

co

nte

nt,

wt

%

rod 302

Height, mm

0

0,1

0,2

0,3

0,4

0,5

0 1000 2000 3000 4000

rod 21 rod302

Height, mm

Fe c

on

ten

t, w

t %Nb Fe

Fe content in GT and CT matrix remains unchanged in height, but Nb content changes. The level

of Fe and Nb in the matrix are determined by the redistribution between SPP and solid solution

during irradiation. The cladding temperature (~ 350° C) is higher than CT, GT and SG (coolant T

°C) and increases with elevation coordinates. The matrix and SPPs composition under irradiation

is defined by the temperature and the neutron fluence (or damage dose).

The element distribution investigation was carried out across the sample (from spacer grid

through the weld joint to the rigid angle "SG-RA") at level 2000 mm.

SGs and RAs are made of different alloys: SGs - E110, RAs - E635.

The analysis shows that tin from E635 alloy does not diffuse into E110 alloy;

iron from E635 alloy extends to a greater distance into E110 alloy.

Distribution of Sn, Nb and Fe across the weld joint

core (E110 and E635 alloys)

E110E110

E635E635

Sn

Nb

Fe

TEM microstructure of the weld core Martensitic structure at level 2000 mm and fine RIPs at 900 mm

a- loops and c-dislocations in the welded joint at the level 3000 mm

SPPs in the material were dissolved by heating during welding. Highly dispersed radiation-induced precipitates

(RIP) were found. The dislocation structure is characterized by ordered a-dislocation loops and c-dislocations

Irradiation shape changesThe effect of irradiation-induced growth is observed in Zr alloys under irradiation in the absence

of stress. Irradiation creep developes when load is applied to the material under irradiation.

During the reactor performance, only CT is free of mechanical stress, its dimensional change is

due to irradiation growth. CT elongation is in a good agreement with irradiation-induced growth of

E635 alloy samples irradiated in BOR-60 at ~ 320°С and corresponds to the fluence range (2,1-2,6) ×

1026 m-2 (0.1MeV) in the VVER-1000 (17-20 dpa).

19

The fuel rod outer diameter with E110 cladding due to creep under differential pressure "coolant -

fuel rod" decreases up to the burn-up ~50- 55 MW·d/kgU. At higher burn-ups a change occurs in the

opposite direction - the effect of the so-called "inverse" strain. At the same fuel swelling the gap

between the E635 cladding and fuel must be maintained even at very high burn-up. Due to a high

strength of the E635, the effect of "inverse" strain is hardly possible even for the ~ 80 MW·d/ kgU.

Dependence of the outer diameter of fuel rods with

E110 and E635 alloys cladding on the burn-up

The maximal oxide thickness vs time of operation of E635

● - fuel rod claddings, □ - GT, ▲- angles of the frame

20

The analysis of the corrosion condition of cladding, GT, CT, and angles shows that

the kinetics of oxidation can be approximated by linear dependence, which is

influenced by differences in conditions of the test, as shown by the changes in the

oxide thickness of the structural elements of FAA.

21

Oxidation and hydrogenationThe oxide film thickness on the rods, GT and CT after 6 years of operation increases with

elevation coordinates to a height of 2900-3000 mm, with its subsequent decrease.

0

10

20

30

40

50

60

80

0 500 1000 1500 2000 2500 3000 3500 4000

Height, mm

CTGT3GT9rod 138

70

ox

ide t

hic

kn

ess, μ

m

Temperature dependence of hydrogen content in the E635 GT (■,♦) and CT (▲) is shown. The

temperature above 305 °C corresponds to the height altitude above 3000 mm (low fluence). The

hydrogen content in the first approximation, linearly dependent on the oxide film thickness.

22

Dependence of hydrogen content on the oxide film thickness

in the E635 alloy elements of FAA

GT, CT, angles –

double-sided oxidation

claddings

0

100

200

300

20 40 60 80 100Oxide film thickness, μm

H c

on

ten

t, p

pm

rod 21rod 138rod 302

23

The oxidation is accompanied by the absorption of hydrogen, which was dissolved in the

material, and precipitated in the form of zirconium hydride at cooling. Figure presents

results of hydrogen content calculation through the hydrides number density in the

metallographic images and the measured values of hydrogen content in E635 FA

elements.

Hydrogen content dependence on the oxide film

thickness in the E635 alloy FA elements

measurements: ∆ - rod, ◊ - GT, ○- CT, □ - angle;

calculation: ▲ - rod, ♦ - GT, ●- CT, ■ - angle

24

CONCLUSION Е635 alloy have confirmed high reliability as VVER-1000 fuel assembly material for a 6-year-

long performance to burn-up ~ 72 MW·d/kgU.

Dimensional changes, corrosion and tensile properties of the items did not reach the values that

prevent their further exploitation:

- closing gap "fuel - claddings" of fuel rods with E635 claddings does not occur;

- fuel rods elongation does not exceed 0.4%;

- CT and rigid angle elongation is within 0.180.21%;

- GT elongation does not exceed 0.14%;

- cladding oxide film thickness is 80 μm

Microstructural studies, hydrogen content and tensile properties of the claddings have shown

that E635 alloy retained sufficient corrosion and irradiation resistance.

Hydrogen content in the claddings is not more than 0.03%, varies with height elevation,

correlates with the oxide film thickness and temperature. Oxidation and hydrogenation of GT, CT,

rigid angles and weld joints are not a limiting factor for long-term FAA skeleton operation.

Strength characteristics of guide thimbles practically unchanged with the elevation coordinate

and exceed the level of cladding properties; their total elongation exceed 4.9%.

The oxide film thickness and hydrogen content distribution in FAA elements are determined,

first of all, by thermal irradiation effects (heat flux, temperature and neutron fluence).

Radiation damage of the structure and redistribution of alloying elements during irradiation

influence mainly resistance to shape changes and tensile properties.