Tren de Fuerza 793C

-

Upload

elvis-ariel-rodriguez-ochoa -

Category

Documents

-

view

361 -

download

22

Transcript of Tren de Fuerza 793C

Entrenamiento de Servicio MATERIAL PARA Programa de Certificación EL ESTUDIANTE

Camiones Grandes de Obras Modulo III

Power Train

Nombre del Participante: _____________________________________________________________

Camión a ser certificado: ______________________________________________________________

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 2 -

NOTAS DEL PARTICIPANTE

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 3 -

DESCRICION DEL MODULO OBJETIVOS

DURATION PRE REQUISITES

POWER TRAIN

In this module, you will find a set of sheets titled “Module III – Preparation for Skill Check”. After to study this subject and answer 100% of the questions the participant will be able to perform the “Module III Skill Check Worksheet”.

The participant can use all service literatures available in this room to study and work on each module. The facilitator will be available to provide the necessary guidance about the student’s material. This self study will be conducted according participant’s choice.

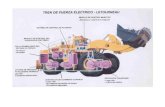

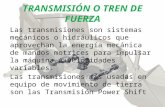

The OHT Power Train module covers the torque converter, transmission hydraulic and electronic systems, rear axle and final drives. Note: Consider that the operation in direct drive of the ICM transmission hydraulic control for 793C is unique in comparison to any other Off-Highway Truck.

OBJETIVOS DEL MODULO

1. Given a “Module III - Preparation for Skill Check sheet – Power Train Hydraulic Circuits”, fill the written questionnaire and submit it to the facilitator’s approval. The service literature’s search is allowed.

2. Given a “Module III – Skill check worksheet – components identification”, choose the necessary tools and service procedures and go to the machine to perform them. The service literature’s search is allowed.

3. Given a “Module III – Skill check worksheet – Power train calibrations”, choose the necessary tools and service procedures and go to the machine to perform it. The service literature’s search is allowed.

4. Given a “Module III – Skill check worksheet – Power train pressure test”, choose the necessary tools and service procedures and go to the machine to perform it. The service literature’s search is allowed.

02:30 h

Be able to search on SIS CD or SIS Web English technical instructions comprehension Use of ET Caterpillar Electrical Schematic interpretation Previous experience supporting Large OHT

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 4 -

Preparación Para las Tareas: Modulo III – Power Train Plan de acción para las tareas – Por favor revise con cuidado las necesidades de su practica y asegúrese que reúne todo antes de empezar las tareas del modulo. Son seis partes que debe completar antes de ir a la maquina

• 1. Cuestionario – Es una serie de preguntas que debera contestar, en algunos casos debera buscar la respuesta todo dependera de sus conocimientos.

• 2. Listado de tareas – Estas son las tareas que debera cumplir para completar este modulo, normalmente se trata de por lo menos una hoja de trabajo con sus instruccciones por cada tarea:

a. Localizacion de componentes del sistema del modulo III.

b. Calibraciones y estrategia del sistema del modulo III.

c. Prueba de presiones del sistema del modulo III.

Nota el ejercicio del ET se puede practicar en el computador antes de ir a la maquina con el ET trainer

• 3. Escoger las herramientas y materiales – En la hoja de materiales y herramientas que recibio en la introduccion, decida que se necesitara para el cumplimiento de cada tarea.

• 4. Conseguir los procedimientos para las tareas – Para realizar la tarea debe seguir una serie de pasos, que normalmete estan en el manual de servicio, debe localizar el procedimiento (copia del libro o impresión del SIS).

• 5. Registrar las especificaciones – Cada tarea tiene una hoja de registro de datos, escriba las especificaciones de acuerdo al manual de servicio donde sea necesario.

• 6. Recibir la aprobacion del facilitador para la realizacion de la tarea – Una vez que cumpilo con todos los requerimientos en la preparacion para las tareas, puede pasar a donde el facilitador para conseguir su aprobacion

Nombre del facilitador: ____________________________ Firma ____________

Hora Inicio: ___________ Fecha __________ Hora Fin: ___________ Fecha __________

Es tiempo de ir a la maquina

Coloque unamarca de

aprobación en el cuadro

cuando termine

cada parte

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 5 -

Large Off-Highway Trucks

Module III – Preparation for skill check

Objetivo 1: Power Train Hydraulic Circuits

1) Media number for 785C Power Train Systems Operation _______________________________

2) Fill the blank with the correct number from TC lockup clutch control schematic:

_____ oil from parking brake release system

_____ oil to transmission lube

_____ oil from transmission charging pump

_____ oil to lockup clutch

_____ oil to station “D”

_____ pilot pressure to the lockup modulation valve

1A

2A

3A

4A

5A

6A

785/789C

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 6 -

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

3) Fill the blank with the correct number from TC and transmission hydraulic system

_____ TC charging oil filter _____ Rear brake oil coolers

_____ Front brake oil cooler _____ TC charging section

_____ Converter scavenge section _____ Parking brake filter

_____ Parking brake retraction valve _____ Diverter valve

_____ Converter outlet screen _____ Rear brake cooling pump (789)

_____ Parking brake release pump _____ Oil to transmission lube

9A

10A

7A

6A

3A

2A

1A

5A

4A

11A 8A

12A

785/789C

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 7 -

4) On the schematic above, use arrows (→) to trace the correct oil flow to the following circuits:

_____ Transmission charging circuit

_____ Transmission oil cooling and lube circuit

_____ TC lockup relay and modulation valve

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 8 -

1

2

3

4

5

6

5) Media number for 793C Power Train Systems Operation _______________________________

6) Fill the blank with the correct number from TC lockup clutch control schematic: _____ oil from transmission charging pump

_____ oil to transmission lube pump

_____ oil from transmission charging pump

_____ oil to lockup clutch

_____ oil to station “D”

_____ pilot pressure to the lockup modulation valve

793C

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 9 -

7 8

910

15

11

13

12

14

16

793C

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

7) Fill the blank with the correct number from TC and transmission hydraulic system

_____ TC charging oil filter

_____ TC outlet orifice and screen

_____ Transmission lubrication section

_____ TC/transmission cooler

_____ Transmission charging section

_____ TC charging section

_____ Up shift solenoid

_____ Downshift solenoid

_____ Lockup solenoid

_____ Transmission scavenge section

_____ TC lockup valve

17

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 10 -

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

8) On the schematic above, use arrows (→) to trace the correct oil flow to the following circuits:

_____ Transmission charging circuit

_____ TC charging circuit

_____ Transmission oil cooling circuit

_____ Transmission oil lube circuit

793C

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 11 -

9) Fill the blank with the correct number from Transmission ICM Hydraulic System (785/789C)

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

33A

____ Selector valve group

____ Charging pump

____ Lube pump

____ Pump pressure tap

____ Pilot oil pressure tap

____ Lockup solenoid

____ Downshift solenoid

____ Upshift solenoid

____ Upshift pressure tap

____ Downshift pressure tap

____ Priority reduction valve

____ Neutralizer valve

____ Rotary selector spool

____ Dual stage relief valve

____ Lubrication relief valve

____ Filters

____ Pressure control group

____ Cooler bypass valve

785/78931A

21A 24A

20A

32A

22A18A

30A

29A

35A

19A 23A

26A

25A

28A 27A

34A

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 12 -

10) Fill the blank with the correct number from Transmission ICM Hydraulic System

33

____ Selector valve group

____ Charging pump

____ Lube pump

____ Pump pressure tap

____ Pilot oil pressure tap

____ Lockup solenoid

____ Downshift solenoid

____ Upshift solenoid

____ Upshift pressure tap

____ Downshift pressure tap

____ Priority reduction valve

____ Neutralizer valve

____ Rotary selector spool

____ Dual stage relief valve

____ Lubrication relief valve

____ Clutch supply pressure

____ Pressure control group

34

793C

19

18

20

21

22

23

24

26

27 29

25

28

31 30

32

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 13 -

11) Fill the blank with the correct number from Valve Station

_____ Drain

_____ Clutch supply rail (pressure)

_____ Oil pressure to clutch

_____ Clutch pressure tap

_____ Decay orifice

_____ Load piston orifice

_____ Load piston plug

_____ Selector piston

_____ Load piston

_____ Modulation reduction valve

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

36

37 38

45 44

43

42

41

40

39

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 14 -

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

12) Explain the function of:

Priming bleed orifice (793C) - __________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Lock up reducing valve (all trucks) - _____________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Transmission pressure control valve (all trucks) - ___________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Priority reduction valve (793C) - _______________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Priority reduction valve (785/789C) - ____________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Neutralizer valve (all trucks) - __________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Cooler bypass valve (785/789) - ________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 15 -

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

REAR AXLE FILTER SYSTEM

1

2

3

4

5 6

13) Fill the blank with the correct number from rear axle filtering system schematic:

_____ Flow control valve

_____ Oil filter

_____ Differential oil pump

_____ Rear axle

_____ Suction screen

_____ Temperature / pressure control valve

14) On the schematic above, use arrows (→) to trace the correct oil flow on rear axle filtering system at

temperatures below 43° C (110° F). Done

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 16 -

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power Train Hydraulic Circuits

15) The Transmission Chassis ECM controls the following functions: hoist system rear axle cooling automatic lubrication grease neutral start function back up alarm throttle back up.

16) Fill with “x” all characteristics related to each component. Note: each component can have more than one characteristic

COMPONENT INPUT OUTPUT ANALOG SIGNAL

DIGITAL SIGNAL

FREQUENCY SIGNAL

SOLENOID ON / OFF

Transmission output speed sensor Body position sensor

Engine output speed sensor Transmission oil temperature sensor

Torque converter oil temp sensor Hoist raise solenoid Downshift solenoid Auto lube solenoid

Starter relay

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 17 -

17) Write the meaning of the following messages from transmission ECM events:

Message Meaning

Shift counter

Lock up counter

Coasting in Neutral Counter

Transmission Abuse

Engine Overspeed

Machine Overspeed

18) Use the numbers from 1 to 6 to fill the blanks to define the actions priority the technician should follow during any power train hydraulic pressure test: ____ Write a list of necessary tools to perform the test ____ Have the correct test procedure in your hands before to perform it ____ Check if the oil is at operating temperature ____ Check if the filters and screens are clean ____ Write the machine model, serial number, hour meter, component s/n, before to start the test ____ Choose the correct literature media number.

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power train

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 18 -

19) Use the numbers from 1 to 6 to fill the blanks to define the actions priority during the procedure to check the clutch control valve (station) primary pressure. (initial pressure). ____ Record the pressure and compare with the service manual table ____ Remove the load piston plug off, at the related clutch ____ Check if the transmission test cover _______________ is installed ____ Remove the drive axles from the machine or disconnect the drive shaft from T.C. ____ Manually engage the shift related to the clutch control valve to be checked ____ Install the ________________ gauge at the related clutch control valve (station)

20) Write 3 conditions that can cause the following: Problem: The pressure in one clutch at high idle is not correct but the primary pressure in the same clutch is correct.

1 - ______________________________________________________________________________

2 - ______________________________________________________________________________

3 - ______________________________________________________________________________

21) Write the following part numbers for the parts assembled inside the clutch control valve 5 (station F)

Part number Name

________________ Spring inner

________________ Spring outer

________________ Plug orifice (decay orifice)

22) By consulting the Service Manual module or SIS Web, fill the “Module III Skill Check Worksheet – Power Train Pressure Test” (attached), with the specifications necessary to perform the test: print a copy of the procedure from SIS and follow it.

Done

Large Off-Highway Trucks Module III – Preparation for skill check

Description: Power train

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 19 -

MAQUINAS

HERRAMIENTAS

Maquinas Requeridas 1-Camión

Herramientas Requeridas ______ 1 Lap-top computer with ET v3.2 and VIMSpc99 v.2.0.3. ______ 1 7X1701 Communications Adapter with SPM NEXG4523

installed in ______ 1 7X1425 cable (lap-top to CA) ______ 1 1394166 Universal Data Link Cable or ______ 1 1714400 Communication Adapter II Group ______ 1 1960055 Cable ______ 1 VIMS Simulator (OHT configuration) ______ 1 7X1695 timing probe cable ______ 1 6V2197 timing probe magnetic pickup ______ 1 6V3093 timing probe adapter sleeve ______ 1 1279797 cable (lap-top to VIMS download port) ______ 1 8T5200 signal generator ______ 1 7X6370 cable 3-pin DT connector breakout Tee ______ 1 9U7330 Fluke 87 (28-16) ______ 1 7X1710 probe group ______ 1 1U5481 pressure gauge group ______ 1 1U5482 pressure adapter group ______ 1 6V6064 transm. test cover assy. ______ 1 4C4892 fitting gp (32-54)** or ______ 1 7X0871 Tee/1 6V8398 o-ring seal/1 6V3965 nipple assy/

1 3J1907 o-ring seal ______ 1 6V7830 tetra gauge ______ 1 4C4890 hydraulic test gp ______ 1 6V4157 test group ______ 1 6V9509 face seal plug ______ 1 6V9511 face seal plug ______ 1 6V9830 cap assy ______ 1 6V9831 cap assy ______ 1 6V3935 nipple (to read the front brk cooling system press

at hoist valve 793C)

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 20 -

______ 1-Cronometro (Stop Watch) ______ 1 infrared thermometer ______ 1 mechanical tool box (including 9S1721 extension

1/4"square drive, 9U6635 reversible ratchet, 5P3277 tape measure, 5P3920 rule, vernier caliper, Hex key wrench mm and inch (3/8" steering cutout/cut-in)

______ 1-5P 3277 Cinta Métrica (Tape Measure) ______ 1-Scale de 150mm ______ 1 8T0853 pressure gauge ( 85 psi) ______ 2 8T0854 " " ( 145 psi) ______ 2 8T0859 " " (3600 psi) ______ 2 8T0860 " " (5800 psi)

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 21 -

MATERIAL DEL ESTUDIANTE

MATERIAL DEL ESTUDIANTE

Descripción Form No.Camión de Obras 793C

Specification 793C 3500B/3500B High Displacement SENR1122 Specification 793C OHT Power Train SENR1448 Specification 793C OHT Steering System SENR1451 Specification 793C Hydraulic System SENR1457 Specification 793C Air System and Brakes SENR1453 Spec, S.O., T & A 793C Traction Control System SENR2986 Systems Operation 793C Automatic Lube System SENR4724 Systems Operation Exhaust by pass 793/B/C OHT SENR5092 Systems Operation 3500/B High Disp. Engines SENR1123 Systems Operation 793C Power Train Elec Control SENR1502 Systems Operation 785/797 VIMS Payload Mon… RENR2625 Systems Operation 793C Air System and Brakes SENR1592 Systems Operation 793C Hydraulic System SENR1504 Systems Operation 793C Power Train RENR2675 Systems Operation 793C Steering System RENR1452 OHT Vital Information Management System (VIMS) RENR2630____ Vital Information Management System (VIMS) SENR6059 T & A, Troubleshooting VIMS RENR2631 793 Power Train Testing & Adjusting SENR1450 Systems Operation 793C OHT Road Analysis Control RENR2636 793C OHT Electrical System (pub date 2000/08/01) RENR2642 793C OHT Electrical System (pub date 1998/10/01) SENR1541 793C OHT Hydraulic Schematic SENR1564 793C Specalog AEHQ5186 793C Operation & Maintenance Manual SEBU7175 Machine Fluids Recommendations SEBU6250

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 22 -

MATERIAL DE ENTRENAMIENTO

Videos _____ 793C OHT Service Introduction SEVN4016 _____ 3500 Engines EUI Service Introduction SEVN2241

CDs _____ 3500B MEUI Fuel System RENR1395 _____ CAT C Series Mining Trucks YERA3501

Libros de Referencia _____ Operation & Maintenance Manual SEBU7175 _____ Service Manual SENR1540 _____ Parts Book SEBP2791

Material de entrenamiento _____ 793C Off-Highway Trucks SESV1682 _____ 3500B Engine Controls (EUI) SESV1681

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 23 -

Large Off-Highway Trucks

Module III – Skill Check Worksheet

Objective 2: Components Identification (large OHT)

Go to the machine and perform the “Skill Check Worksheet”. The facilitator will observe you during the activity. When you finish the activity ask him to sign off this “Skill Check Worksheet”.

1) Go around the machine and identify the following components and/or pressure check points related

to power train system:

_____ Lockup modulation valve

_____ T.C outlet relief valve, pressure check point

_____ T.C. oil temperature sensor

_____ T.C. inlet relief valve, pressure check point

_____ Lockup reducing valve

_____ Lockup pressure check point

_____ T.C. charging pump

_____ Transmission lube pressure checkpoint

_____ Transmission charging pressure pump, checkpoint

_____ Transmission hydraulic control pilot pressure, check point

_____ Lock up solenoid

_____ Downshift solenoid

_____ Transmission magnetic screen

_____ Transmission output speed sensor

_____ Rear axle temperature/pressure control valve

_____ Differential thrust pin

_____ Service/retarder brake switch

Nombre del facilitador: _______________________________________ Firma _______________

Hora Inicio: ____________ Fecha _______________

Hora Fin: ____________ Fecha _______________

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 24 -

Large Off-Highway Trucks

Module III – Skill Check Worksheet

Objective 3: Power Train Calibrations (large OHT) Choose the literature and tools necessary to perform this activity. Go to the machine and perform the “Skill Check Worksheet”. The facilitator will observe you during the activity. When you finish the activity ask him to sign off this “Skill Check Worksheet”.

1) Take a laptop with ET installed, go to the machine, communicate with the transmission ECM:

- Print to file the transmission/chassis configuration. Create a new file title “793C Tinaja” and

type the description “Transmission/chassis ECM”

2) Do the following calibrations: - Transmission gear limit - 4

- Body up gear limit - 3

- Print the new configuration to the same file and description “New config”.

Nombre del facilitador: _______________________________________ Firma _______________

Hora Inicio: ____________ Fecha _______________

Hora Fin: ____________ Fecha _______________

Literature Form

Tools, accessories

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 25 -

Module III – Skill Check Worksheet

Objective 4: Power Train pressure test

Choose the necessary tools, service procedures and write the desired value cells before to go

to the machine.

TORQUE CONVERTER PRESSURE TESTS

Machine Serial No. ___________________________Machine Hours: ________________________

Transmission Serial No: _______________________Transmission Hours: _____________________

VISUAL CHEKS

Oil Level: __________________________________Oil Viscosity: __________________________

Air/Water in Oil? _____________________ Oil Filter Examination: ___________________

1) TORQUE CONVERTER OUTLET RELIEF VALVE PRESSURE (Large OHT)

Tool List:

Specification Actual

Oil temperature

Transmission gear

Engine rpm

Read the pressure at tap _______

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 26 -

Tool List:

Specification Actual

Oil temperature

Transmission gear

Engine rpm

Parking brake

2) TORQUE CONVERTER LOCKUP CLUTCH PILOT PRESSURE (Large OHT)

Read pressure tap

_______

Oil temperature

Transmission gear

1) Engine rpm:

2)

Parking brake

Additional instruction

1)

3) TORQUE CONVERTER LOCKUP CLUTCH SIGNAL PRESSURE (Large OHT)

Read the pressure at tap

_______ 2)

Large Off-Highway Trucks Module III – Skill check worksheet

Objective 4: Power train pressure test

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 27 -

Tool List:

Specification Actual

Oil temperature

Transmission gear

Engine rpm:

Parking brake

Additional instruction

4) TORQUE CONVERTER LOCKUP CLUTCH MAXIMUM PRESSURE (Large OHT)

Read the pressure at tap

Oil temperature

Transmission gear

Engine rpm:

Parking brake

Additional instruction

5) TORQUE CONVERTER LOCKUP CLUTCH PRIMARY PRESSURE (Large OHT)

Read the pressure at tap

Large Off-Highway Trucks Module III – Skill check worksheet

Objective 4: Power train pressure test

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 28 -

LOCKUP SOLENOID DE-ENERGIZED 785/789C

Specification Actual

LI HI LI HI

6) PUMP PRESSURE (minimum)

(maximum)

Transmission oil temperature during tests

7) LUBE PRESSURE

8) Write what clutches are engaged for each transmission speed (Large OHT)

TRANSMISSION SPEED

ENGAGED CLUTCHES

TRANSMISSION SPEED

ENGAGED CLUTCHES

TRANSMISSION SPEED

ENGAGED CLUTCHES

NEUTRAL 1 THIRD speed REVERSE

NEUTRAL 2 FOURTH speed

FIRST speed FIFTH speed

SECOND speed SIXT speed

(Large OHT) 9) MAXIMUM CLUTCH PRESSURE (Large OHT) Load piston plug installed. Lockup sol disconnected

STATION CLUTCH Specification Actual

LI HI LI* HI*

B 1 C 3 F 5 G 6

Large Off-Highway Trucks Module III – Skill check worksheet

Objective 4: Power train pressure test

Camiones Grandes de Obras Material Para Versión Julio 2001 el Estudiante

- 29 -

10) Check the transmission pump pressure adjust versus transmission clutch supply rail when the 793C is operating both in torque converter and direct drive

DUAL STAGE RELIEF LOCKUP SOLENOID DE-ENERGIZED SPECS ACTUAL LI HI LI HI

PUMP PRESSURE (AA - at pressure tap L)

(Transmission Neutral)

Transmission oil temperature during tests

DUAL STAGE RELIEF LOCKUP SOLENOID ENERGIZED

SPECS ACTUAL

LI 1300 RPM LI 1300 RPM

PUMP PRESSURE (EE) (at station C)

xxxxxxxxx

xxxxxxxxx

PUMP PRESSURE (DD) (at pressure tap L)

xxxxxxxxx xxxxxxxxx

LUBE PRESSURE (see manual) 5 TO 65 kPa (.5 to 10 psi)

160 ± 50 kPa (23 ± 7 psi)

Nombre del facilitador: _______________________________________ Firma _______________

Hora Inicio: ____________ Fecha _______________

Hora Fin: ____________ Fecha _______________

793C ONLY

Large Off-Highway Trucks Module III – Skill check worksheet

Objective 4: Power train pressure test

NOTE: priority reducing valve is used to set pressure (DD) in direct drive only. Setting pressure (DD) in direct drive to 2310±70 kPa (335±10psi) will cause the pilot pressure (BB) to be approximately 2400 to 2750kPa (350 to 400 psi) when the machine is in torque converter drive.

Do not shim transmission priority reducing valve in order to control pilot pressure. The pilot pressure is a result of setting the pressure of the transmission charging pump section when the machine is in direct drive.