Oi 2011 2 Topic 2 Student

-

Upload

julio-alberto-luna-pacho -

Category

Documents

-

view

218 -

download

0

Transcript of Oi 2011 2 Topic 2 Student

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Project planning

Departament d’Organització d’Empreses

ETS d’Enginyeria Industrial de Barcelona

Universitat Politècnica de Catalunya

Enginyeria Industrial

Organització Industrial

2.1

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

What is a project? Features

The internal organization of the companies is prepared to respond to their

needs and regular activities.

There are some singular activities, we call them projects, that require to

establish special procedures and organization.

A project can be defined as a temporary effort developed to

create a unique product or service.

General features of a project

Temporality (defined beginning and end)

Unique product, service or result that is not obtained in usual activities

Progressive development

Low automation but intensive use of workforce

It involves the management of resources (time, budget, workforce, ...)

2.2

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

What is project management?

Examples

Building a plant or warehouse

Develop and launch a new product

Automation of a production line

Implement new software for warehouse management

Relocation of an office, plant, warehouse….

New computing application

Rearrangement of workforce

Implement a new management model

Computerization of procedures

Implement ISO 9000 quality standard (or others)

It’s the application of knowledge, skills, tools and

techniques to the activities of the project to achieve the

project requirements.

Project Management Institute. Project Management Body Of Knowledge.

2.3

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Project life cycle

Project

“GO”

Decision

Majors

Contracts

Let

Full

Operations

100 %

STAGE 1 STAGE II STAGE III STAGE IV

Previous studies

Project viability

Investment approval

Product launchingDevelopment

engineering

Construction and

assembly

Supplies

Project definition of the

basic engineering project

Programming and budget

Contracting

TIME

% P

erc

en

t C

om

ple

te

Source: Project Management Institute. A Guide to the project management body of

knowledge, PMI Standards Committee, Maryland, USA, 1996

2.4

Installation

Substantially

Complete

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Features and information of the activities

Features

Definable and understandable by participants

Manageable, the responsibility must be assigned to a single person

Possibility to carry out estimates in terms of duration, cost,…

Independent and distinguishable, to some extend, from other activities

Integrated with the rest of activities to set up the project

Measurable to establish progress of the project

Adaptable to the project requirements

Information

Identifying: code, description, executor, responsible

Temporary: duration, foreseen start and end dates (updatable)

Resource requirements: type and quantity of the needed resource

2.5

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Links classification

MINIMUM MAXIMUM

Temporary

location

Succession

LINKS

Temporary location

SuccessionPotential

Disjunctive Inability to perform two activities (i , j)

simultaneously

Cumulative R(k , t): available quantity of resource k

at time t

t

ij

t

ij

2.6

ti

f

ft i

ti

F

Ft i

att ij btt ij

a b

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Classification and treatment of problems

PROJECT

SCHEDULING

PROBLEMS

Compatibility

Heuristics (kind Manpower

scheduling, greedy methods)

Balancing

Heuristics (such as, Burguess-

Killebrew)

Potential Tools:

Gantt, PERT and Roy diagrams

Disjunctive Heuristics methods

Cumulative

RESULTS: The program (schedule of activities, resource allocation,

timing of receipts and payments ...)

2.7

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Example: list of activities

A

B

C

D

E

F

G

H

I

J

Technical specifications

Definition of operations

Assembly P1

Assembly P2

Dovetailing P1-P2

Component labelling P1-P2

Assembly P1.2

Assembly P2.2

Visual inspection P2.2

Plug in P1.2 to P1-P2 + Test

1

1

2

3

5

2

3

2

2

1

-

A

B

B

C, D

E

C

D

H

G, F

2

2

1

1

1

1

1

1

1

1

Code Activity name Duration Preced. Resources

2.8

Project: prototype wiring for pleasure craft

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Example: Roy diagram of precedences

ti: 0 Ti: 0 mi: 0

Technical spec.

Di: 1Cod.: A

ti: 1 Ti: 1 mi: 0

Def of operations

Di: 1Cod.: B

ti: 2 Ti: 3 mi: 1

Assembly P1

Di: 2Cod.: C

ti: 2 Ti: 2 mi: 0

Assembly P2

Di: 3Cod.: D

ti: 5 Ti: 9 mi: 4

Assembly P2.2

Di: 2Cod.: H

ti: 5 Ti: 5 mi: 0

Dovetailing P1-P2

Di: 5Cod.: E

ti: 4 Ti: 9 mi: 5

Assembly P1.2

Di: 3Cod.: G

ti: 10 Ti: 10 mi: 0

Labelling P1-P2

Di: 2Cod.: F

ti: 7 Ti: 11 mi: 4

Visual insp. P2.2

Di: 2Cod.: I

ti: 12 Ti: 12 mi: 0

Plug P1.2 & P1-P2 + Test

Di: 1Cod.: J

End

Start

Project: prototype wiring for pleasure

craft

2.9

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Example: Roy diagram and critical path

A

0

00B

0

11

E

0

55

F

0

1010

G

5

94

H

4

95I

4

117

J

0

1212

C

1

32

D

0

22End

0

1313

St..

0

00

1

1

1 3

3

2 2

1

2

5

3

2

2

2.10

Project: prototype wiring for pleasure craft

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Example: PERT diagram and critical path

2.11

I II V VI VIII

III

IV

VII

A B E F J

IH

G

C

D

1 1

2

3

3

5 2 1

22

0/0 1/1 2/2

4/5

5/5

5/510/10

7/11

12/12

13/13

Project: prototype wiring for pleasure craft

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

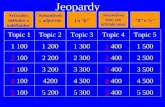

Example: table of results

A

B

C

D

E

F

G

H

I

J

Technical specifications

Definition of operations

Assembly P1

Assembly P2

Dovetailing P1-P2

Component labelling P1-P2

Assembly P1.2

Assembly P2.2

Visual inspection P2.2

Plug in P1.2 to P1-P2 + Test

1

1

2

3

5

2

3

2

2

1

Cód. Activity name(i) di

0

1

2

2

5

10

4

5

7

12

ti

0

1

3

2

5

10

9

9

11

12

Ti

0

0

1

0

0

0

5

4

4

0

mi

C

C

C

C

C

C

Crit.

Ordered according to increasing margin

2.12

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Example: Gantt diagram

1 2 3 4 5 6 7 8 9 10 110

Time

12

Technical specifications

Definition of operations

Assembly P1

Assembly P2

Dovetailing P1-P2

Comp. labelling P1-P2

Assembly P1.2

Assembly P2.2

Visual inspection P2.2

Plug in P1.2 to P1-P2 + Test

A

B

C

D

E

F

G

H

I

J

131 2 3 4 5 6 7 8 9 10 110 12 13

2.13

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Load curves (with overload)

1 2 3 4 5 6 7 8 9 10 110

Time

12

A

B

C

D

E

F

G

H

I

J

1 2 3 4 5 6 7 8 9 10 110

Time

12

0

1

2

3

Re

so

urc

es

13

13

2.14

Technical specifications

Definition of operations

Assembly P1

Assembly P2

Dovetailing P1-P2

Comp. labelling P1-P2

Assembly P1.2

Assembly P2.2

Visual inspection P2.2

Plug in P1.2 to P1-P2 + Test

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Load curves (without overload)

1 2 3 4 5 6 7 8 9 10 110

Time

12

A

B

C

D

E

F

G

H

I

J

1 2 3 4 5 6 7 8 9 10 110

Time

12

0

1

2

3

Res

ou

rce

s

13

13

2.15

Technical specifications

Definition of operations

Assembly P1

Assembly P2

Dovetailing P1-P2

Comp. labelling P1-P2

Assembly P1.2

Assembly P2.2

Visual inspection P2.2

Plug in P1.2 to P1-P2 + Test

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Disjunctive problems

Definition: those in which a disjunctive link exists (when two or more

activities cannot overlap temporarily in their execution).

Can be considered a particular case of the cumulative link.

RESOLUTION PROCEDURE

P1. For each disjunctive link, determine the length of the paths that may

be created between the beginning and the end of the project, with each

of the possible orientations of the disjunctive links (not yet resolved).

For a disjunctive link between activities i and j: ti + di + (D-Tj)

P2. Associate each disjunctive link with the greatest of the lengths of the

new paths that may be introduced.

P3. Consider the link with the greatest associated value and orientate it

in the opposite direction (most favorable).

P4. Introduce the chosen direction of the disjunctive link as a new

potential link. Back to P1.

2.16

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Example: Roy diagram and disjunctives (I)

A

0

00B

0

11

E

0

55

F

0

1010

G

5

94

H

4

95I

4

117

J

0

1212

C

1

32

D

0

22End

0

1313

St.

0

00

1

1

1 3

3

2 2

1

2

5

3

2

2

2.17

3

2

3

2

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Example: Roy diagram and disjunctives (II)

A

0

00B

0

11

E

0

55

F

0

1010

G

5

74

H

4

95I

4

117

J

0

1212

C

1

32

D

0

22End

0

1313

St.

0

00

1

1

1 3

3

2 2

1

2

5

3

2

2

3

3

2

H

2

97I

2

119

2.18

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Cumulative problems

Definition: those in which cumulative links appear (when a limitation in the use of one or more resources is imposed).

The goal, due to the difficulty of the problem, is to find a solution.

Solving methodologies:

create a solution from the very beginning;

Find a better solution starting from a given solution, for example without considering the resource limitation,

Two kinds of procedures can be applied :

Any heuristic algorithm: Manpower Scheduling family (simulation) or Greedy procedures (constructive);

Burgess-Killebrew heuristic algorithm.

2.19

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Example: data and initialization

2.20

0

p

a

c

e f

f

b

d

10

14

4

2

208

Act d Res t T m

a 10 1 0 14 14

b 4 2 10 24 14

c 2 1 0 12 12

d 14 2 2 14 12

e 20 1 0 0 0

f 8 2 20 20 0

0

0

Activity list (according to margin): e,f,c,d,a,b

Activity list (according to early start date): e,c,a,d,b,f

..283

84

3

utbound duration Minimum

units resuorce

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Compatibility problems resolution

Objective: Do not exceed at any time the resources availability.

Starting data: Rank the activity list according to a priority criteria :

E.g. activities based on changes in time (rank the activities in no

decreasing order of early start date).

Procedure body:

Serial sequencing: Schedule the activities at the sooner possible moment,

according to precedence and resources, following strictly the order of the list.

Parallel sequencing: Manpower Scheduling Algorithme

Sequence all possible activities at the same moment, in the order of the list, if possible.

Sequence in the next possible moment the first activity that may, in the order of the list, if possible.

End:

The entire list of activities has been scheduled.

2.21

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Compatibility example (I)

2.22

ef

cd

ab

0 2 16 20 24 28 32

0 2 16 20 24 28 32

36

3610

10

Activities sorted by early start date

Pa

ralle

l G

ree

dy

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Compatibility example (II)

2.23

ef

cd

ab

0 2 16 20 26 2832

0 2 16 20 26 28 32

Activities ordered according to margin

Se

ria

l G

ree

dy

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Solving balancing problems

Burgess and Killebrew Algorithm:

Objective: reduce the overload regarding an average value of resource

consumption (R). This will cause an underload reduction.

Initial solution : obtained considering only potential links and early start

dates of the activities.

Procedure body (from an ordered list of activities):

Assess the postponement of the start of the next activity from the

list until last possible date.

Choose the position of the activity that minimizes overload ():

=(t=1;T) max[0; rt-R] rt: consumption of resource at t

Move to the next activity in the list.

End :

When the overload becomes null.

When all the activity list is covered, without any improvement.

2.24

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Balancing. Final solution

2.25

ef

cd

ab

0 2 16 2014 28

0 2 16 2014 2810

10

Organización Industrial – 2011 – DOE - ETSEIB – UPC

Organització Industrial (Eng. Industrial)

Balancing. Final solution

2.26

ef

cd

ab

0 2 16 20 24 28 32

0 2 16 20 24 28 32

36

3610

10