Fibre Concrete

-

Upload

asyraf-fadzil -

Category

Documents

-

view

6 -

download

0

description

Transcript of Fibre Concrete

4.2 FIBRE REIFORCE CONCRETE

4.2 FIBRE REIFORCE CONCRETEADVANCE MATERIALS IN CONSTRUCTION

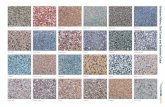

INTRODUCTIONFiber-reinforced concrete (FRC) is concrete containing fibrous material which increases its structural integrity. It contains short discrete fibers that are uniformly distributed and randomly oriented. Fibers include steel fibers, glass fibers, synthetic fibers and natural fibers each of which lend varying properties to the concrete. In addition, the character of fiber-reinforced concrete changes with varying concretes, fiber materials, geometries, distribution, orientation, and densities.

EFFECT OF FIBRE IN CONCRETEFibers are usually used in concrete to control cracking due to plastic shrinkage and to drying shrinkage. They also reduce the permeability of concrete and thus reduce bleeding of water. Some types of fibers produce greater impact, abrasion, and shatterresistance in concrete. Generally fibers do not increase the flexural strength of concrete, and so cannot replace momentresisting or structural steel reinforcement. Indeed, some fibers actually reduce the strength of concrete.

Polypropylene and Nylon fibers can:I)Improve mix cohesion, improving pumpability over long distances

II)Improve freeze-thaw resistance

III)Improve resistance to explosive spalling in case of a severe fire

IV)Improve impact resistance

V)Increase resistance to plastic shrinkage during curing

ADVANTAGES

Steel fibers can:I)Improve structural strengthII)Reduce steel reinforcement requirementsIII)Improve ductilityIV)Reduce crack widths and control the crack widths tightly, thus V)improving durabilityVI)Improve impact and abrasionresistanceVII)Improve freeze-thaw resistance

Blends of both steel and polymeric fibers are often used in construction projects in order to combine the benefits of both products; structural improvements provided by steel fibers and the resistance to explosive spalling and plastic shrinkage improvements provided by polymeric fibers.

In certain specific circumstances, steel fiber can entirely replace traditional steel reinforcement bar in reinforced concrete. This is most common in industrial flooring but also in some other precasting applications. Typically, these are corroborated with laboratory testing to confirm that performance requirements are met. Care should be taken to ensure that local design code requirements are also met, which may impose minimum quantities of steel reinforcement within the concrete. There are increasing numbers of tunnelling projects using precast lining segments reinforced only with steel fibers.

Micro-Rebar has also been recently tested and approved to replace traditional reinforcement in vertical walls designed in accordance with ACI 318 Chapter 14. [3]

DISADVANTAGEThe main disadvantage associated with the fiber reinforced concrete isfabrication. The process of incorporating fibers into the cement matrix is labor intensiveand costlier than the production of the plain concrete. The real advantages gained by theuse of FRC overrides this disadvantage.