A Revisar IJPR Septiembre 2

-

Upload

orlandoduran -

Category

Documents

-

view

9 -

download

0

Transcript of A Revisar IJPR Septiembre 2

-

5/25/2018 A Revisar IJPR Septiembre 2

1/28

ForP

eerRev

iewOnly

Cellular manufacturing system design using groupingefficacy based genetic algorithm

Journal: International Journal of Production Research

Manuscript ID: TPRS-2013-IJPR-0769

Manuscript Type: Original Manuscript

Date Submitted by the Author: 24-May-2013

Complete List of Authors: Pillai, Madhusudanan; National Institute of Technology Calicut, Department

of Mechanical EngineeringCR, Shiyas; National Institute of Technology Calicut, Department of

Mechanical Engineering

Keywords: CELLULAR MANUFACTURE, GENETIC ALGORITHMS, GROUP TECHNOLOGY

Keywords (user):Cellular manufacturing systems, Genetic algorithm, Grouping efficacy,

Alternative routes

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

-

5/25/2018 A Revisar IJPR Septiembre 2

2/28

ForP

eerRev

iewOnly

Page 1 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

3/28

ForP

eerRev

iewOnly

Cellular manufacturing system design using grouping

efficacy based genetic algorithm

Shiyas C. R.

Research scholar, Department of Mechanical Engineering,

National Institute of Technology Calicut, NIT Campus (P.O),

Calicut 673 601, Kerala, India

Phone: 91 9447893107

E-mail: [email protected]

V. Madhusudanan Pillai*

Associate Professor, Department of Mechanical Engineering,

National Institute of Technology Calicut, NIT Campus (P.O),

Calicut 673 601, Kerala, India

Phone: 91 495 2287804, 919895367804

Fax: 91 495 2287250

E-mail: [email protected]

* Author for communication

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

4/28

ForP

eerRev

iewOnly

Cellular manufacturing system design using grouping efficacy

based genetic algorithm

Abstract

This paper presents an algorithm for the design of manufacturing cells and part

families. This algorithm is suitable for arriving at a good block diagonal structure for a

cellular manufacturing design problem with part machine incidence matrix as input. The

objective of this algorithm is the maximization of grouping efficacy which is one of themost widely used measures of quality for cellular configurations. Assignment of

machines to cells is using genetic algorithm and part assignment heuristic is based on an

effective customized rule. A comparison of the proposed algorithm is made with sevenother methods of cell formation by taking 36 problems from the literature and found that

the proposed algorithm is performing much better than the others. Finally, the algorithm

is extended to form configurations with good grouping efficacy when there are alternative

routes.Keywords: Cellular manufacturing systems, Genetic algorithm, Grouping efficacy,

Alternative routes.

1. Introduction

Manufacturing industries with poorly designed production systems and inefficient

manufacturing procedures are facing various problems like increased lead time, highwork in process inventory, reduced product quality, increased production cost, etc.

Cellular manufacturing (CM) allows achieving high productivity in an organization

through efficient configuration of facilities for a medium variety/medium volume

production situation and tries to produce products with as little waste as possible. Theobjective of cellular manufacturing is to have the flexibility to produce a high variety of

medium demand products, while maintaining the high efficiency of a large scale

production by grouping parts and machines according to the similarity between parts. Thedesign of a CMS generally involves grouping of parts with similar design features or

processing requirements into part families and machines into machine cells (Wu et al.

2007). It combines the advantages of both flow shops and job shops with characteristicssuch as reduced cycle time compared to job shops, and increased flexibility and greater

job satisfaction as compared to flow shops. Cellular layouts have been considered

generally efficient than the other traditional layout types given the demand and part mixremains stable over the planning horizon.

2. Literature review

The aim of fundamental cellular manufacturing system (CMS) design problem is the

division of production shop into cells, and parts into families. Numerous methods aredeveloped in this regard. These methods can generally be classified into differentcategories such as (i) array based procedures, (ii) hierarchical clustering, (iii) non-

hierarchical clustering, (iv) graph partitioning approaches, (v) mathematical models, (vi)

Page 3 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

5/28

ForP

eerRev

iewOnly

heuristic techniques, and (vii) other approaches. Generally, part machine incidence

matrix is the input for these models. The objective of the CMS design problem is to get

an output matrix with a good block diagonalisation.

Array-based clustering method assigns machines to cells and group parts to form part-

families, by rearranging the position of the rows and columns based on some procedureto form a good block diagonal structure. In 1980 King introduced the first array based

clustering method named rank order clustering (ROC) which can identify part families

and machine groups simultaneously by rearranging the 1s and 0s in a part machineincidence matrix. Then a modified version of ROC called MODROC was developed by

Chandrasekharan and Rajagopalan (1986a). Bond energy algorithm (BEA) of

McCormick et al. (1972) and the direct clustering algorithm of Chan and Milner (1982)

were also used to create machine groups and part families by array manipulation. Thequality of solution given by array based methods depends on the initial configuration of

the part machine incidence matrix (Goncalves and Resende 2004).

In hierarchical clustering methods, a similarity coefficient or a distance measure isdefined and this approach produces a hierarchy of clusters based on these coefficients.

The single linkage (SLC) and the average linkage clustering (ALC) algorithms bySeifoddini (1989), and the method developed by Yasuda and Yin (2001) are examples for

hierarchical clustering methods. Machine grouping and part-family formation are not

done simultaneously in hierarchical clustering method when compared to array based

clustering techniques.

Non-hierarchical method of cell formation is another class for CMS design. ZODIAC

(Chandrasekharan and Rajagopalan 1987) and GRAPHICS (Srinivasan and Narendran1991) are coming under this category. Better configurations are obtained with non-

hierarchical methods than array based and hierarchical methods. In graph partitioningapproaches machines and parts are treated as nodes of the graph and the operations ofparts as arcs connecting the nodes. Models developed by Kumar and Vannelli (1987) and

Askin and Chu (1990) are based on this approach and simultaneous formation of machine

cells and part-families are not done using this methodology.

Many mathematical programming approaches were also developed to get a good block

diagonal structure for CMS design. Such models consider the cell design problem as an

optimization problem with specific objectives and constraints. Kusiak and Chow (1987)developed a p-median model for CMS design where, the intention is to minimize the sum

of the distances between each product/machine pair. Integer programming model

developed by Choobineh (1988), assignment model by Srinivasan et al. (1990),assignment allocation algorithm (AAA) by Adil et al. (1997) and model by Tarique et al.

(2009) are examples of CMS design models using mathematical programming. In many

of these cases, the solutions are found through some heuristic algorithms.

In recent days the cell formation methods found in the literature are mostly based on

heuristic procedures such as genetic algorithms (GA), simulated annealing (SA), tabu

search, ant colony algorithms, etc. A study by Tavakkoli-Moghaddam (2005) showed that

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

6/28

ForP

eerRev

iewOnly

software packages can solve only small size problems of CMS design compared to these

heuristic approaches. Also, it was noted in their paper that LINGO, an optimization

package sometime provides local optima while GA and SA have reached the globaloptima for the same problem. They are generally used for a systematic randomized

search towards the optimum as part of the cell formation procedure or part-family

formation. These approaches are applied when developing a mathematical model isdifficult or computational time is high while using a software package, particularly for

large problems with data which are difficult to group. In these approaches, there is a step

by step procedure to solve the problem with an objective that has to be minimized (Cost,distance measure, etc) or to be maximized (Similarity function, grouping efficacy, etc).

GA is used by majority of researchers because CMS design problems are combinatorial

optimization problems and their solution can be represented as a combination of

numbers. Coding of solution in the form of chromosome, which is an important part ofGA, is easy because of the above said nature of the problem. Rojers and Kulkarni (2005),

Goncalves and Resende (2004), Mak et al. (2000), Wu et al. (2006), Onwubolu and

Mutingi (2001), Tarique et al. (2009), and Pillai and Subbarao (2008) had used GA based

procedure for CMS design. Pillai and Subbaro (2008) (for CMS design under multi-period demand) used binary numbers for representing a solution because same machine

type is allowed in more than one cell and the objective is to minimize intercell movementand machine acquisition costs. Tarique et al. (2009) (with part machine incidence matrix

as input) used integer numbers for chromosome representation as each machine type is

allowed in one cell alone and their aim is to maximize the grouping efficacy. Sarac and

Ozcelik (2012) developed a GA based heuristic for cell design which has three differentselection and crossover operators.Arkat et al. (2007), and Zolfaghari and Liang (1998)

used simulated annealing for solving their cell design models while Islier (2005) used an

ant colony algorithm. Lin and Ying (2012) in their study, developed a two-level multi-start simulated annealing (TLMSA) heuristic with the objectives of simultaneously

minimising makespan and total flow time for scheduling operations in a manufacturingcell. Zolfaghari and Liang (2002) conducted a comparative study in applying GA,simulated annealing and tabu search for cell design problems and found that GA is

performing better than tabu search method for models that have large number of

parameters like processing time, machine capacity, lot size, etc. Their study also showed

a good performance of SA compared to GA and tabu search for large size problems.

Other approaches for CMS design include fuzzy programming (Shanker and Vrat

1999), and neural network based methods (Pandian and Mahapatra 2008, Won and Currie2007) and are used less compared to methods discussed previously. Recently, some new

approaches are also found in the literature like GRASP - a heuristic to obtain lower

bounds for the optimal solution of a manufacturing cell formation problem (Diaz et al.2012), manufacturing cell design using state-of-the-art constraint programming (CP)

technique and Boolean satisfiability (SAT) technology (Soto et al. 2012), CMS design

models considering operation time (Nouri and Hong 2012) and cell load variation (Nouriand Hong 2013) using bacteria foraging algorithm (BFA), and firefly-inspired algorithm

for cell design (Sayadi et al. 2013).

Page 5 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

7/28

ForP

eerRev

iewOnly

Most of the CMS design models consider only a single process routing. But, in real

situations more than one process route may be possible and considering such an aspect in

the cell design model will lead to better configurations. Consideration of alternativeprocess routes provides some additional flexibility in the design of CMS (Ameli and

Arkat, 2008) and is called routing flexibility. If multiple process routes exist to provide

more production flexibility, intercell material movements can be further reduced (Cao etal., 2009). Caux et al. (2000) used an approach which combines a simulated annealing

method for the cell design and a branch-and-bound method for the route selection.

Kazerooni et al. (1997) developed a model for CMS design which divided the cell designproblem into three sub-problems. The objectives of sub-problems are to find the best

route selection, grouping of machines into cells and formation of part families, and they

used GA to obtain the best configuration.

We can see from different methods of cell formation that majority of the existing

methods suffer from many disadvantages like difficulty of getting good solutions for

large problems, extensive computational time, difficulty in getting good solution for ill-

structured matrices, etc. Some algorithms employ systematic randomized search forforming machine groups as well as part families. In such situations it is not only very

difficult to reach the global optima but also takes a large number of iterations to reach agood solution which in turn increases the computational time. Poor quality solution is

another problem in such situations. Some of these methods are not performing well in

case of problems with ill-structured data, while they give good result for input data which

can be grouped easily. For ideal situations in which perfect grouping are possible, almostall methods lead to 100% efficient solution. The proposed model reduces some of these

defects. The objective of the proposed algorithm and Tariqu et al.(2009) are similar, but

the quality of the best solutions obtained is different. A comparison between the twoapproaches is given in Table 1.

Table 1 Comparison of the proposed algorithm with the algorithm of Tarique et al.(2009)

Proposed algorithm Algorithm by Tarique et al. (2009)

Simple genetic algorithm A hybrid algorithm of GA and local search

heuristic

Best grouping (Number of cells) will be

determined automatically by the algorithm

Algorithm starts with a fixed number of

cells so the designer has to experiment withdifferent number of cells to get the best

grouping

The machine grouping is carried out

randomly by chromosomes represented byintegers which are limited to the number ofmachine types

The machine grouping is carried out

randomly by chromosomes represented byintegers which are limited to the number ofcells

Part assignment is done with a simple

customized rule in a view to increase the

grouping efficacy. This will increase the

chance of reaching a better solution withina short time.

Part assignment is also done randomly as a

result its compatibility with machine

groups have to be checked and repair is

required for eliminating infeasiblesolutions.

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

8/28

ForP

eerRev

iewOnly

An extended algorithm is also proposedwhich can handle alternative routes

available to a part

This algorithm cannot be used forsituations where multiple routes exist.

Like Tarique et al. (2009) many models (Kusiak and Chow 1987, Srinivasan et al.

1990, Rogers and Kulkarni 2005, Mak et al. 2000, Onwubolu and Mutungi 2001, Arkatet al. 2007 and Islier 2005) had set the number of cells in advance which restrict the

solution space. The basic aim of this paper is to develop an algorithm for machine/part

grouping such that the resultant output should give the number of cells, machines in each

cell and part families, and the grouping efficacy should be the maximum for the design.For assigning machines into cells a GA is developed. The part assignment uses a custom-

made rule after machine assignment. Multiple routes can exist in real situations and hence

the algorithm is extended to incorporate alternative routes for the design of cellularmanufacturing system with better grouping efficacy. In the present problem, multiple

routes means that for certain parts there are possibilities for selecting different

combination of machines to carry out their operations and these possibilities are utilised

to design cells that have better grouping efficacy compared to a situation that do not havemultiple routes.

The organisation of remaining part of this paper is as follows: Section 3 discusses onthe proposed algorithm, Section 4 is about the development of GA, an illustrative

example is discussed in Section 5, Section 6 is on the comparison of solution of proposed

algorithm with the solution of other methods, Section 7 deals with the extended algorithmfor alternative routes, and Section 8 gives the conclusions.

3. The proposed algorithm

The proposed algorithm is to develop a good block diagonal structure by maximizingthe grouping efficacy for the given part machine incidence matrix.

For measuring the quality of machine/part groups obtained, researchers have

developed different efficiency measures. The quality is measured for the final matrixobtained after block diagonalisation. The grouping efficacy (GE) proposed by Kumar and

Chandrasekharan (1990) is the most widely and popularly used measure for checking the

quality of solutions. A high value of grouping efficacy for a cell design is an indication ofless intercell moves and a good cell utilisation.

The grouping efficacy can be defined as

)()(

vnenGE

+

=

where

GE grouping efficacy

ntotal number of 1s in matrix A;etotal number of 1s outside the diagonal blocks;

vtotal number of 0s inside the diagonal blocks.

Page 7 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

9/28

ForP

eerRev

iewOnly

In this paper an algorithm is developed which generates cell design that maximize this

grouping efficacy.

3.1. The algorithm

The objective function of the cell formation problem is

Maximize Z = Grouping efficacy

The basic tenant of the algorithm involves identifying a random solution initially and

then improving the solution such that grouping efficacy is maximised. A genetic

algorithm (GA) based procedure is used to implement this. The algorithm steps are given

below.

Step 1 : Input the part machine incidence matrix and algorithm parameters

Step 2 : Randomly generate initial population representing the machine cells

Step 3 : Assign parts to these cells based on the customized ruleStep 4 : Calculate grouping efficacy values for the members of population which is the

fitness valueStep 5 : Form subsequent generation by performing operations like reproduction, cross

over, mutation, and replacement strategy. Perform part-assignment in the new

generation.

Step 6 : Evaluate the offspring and stop the algorithm when the termination criteria is metand select the configuration with maximum grouping efficacy else go to step 5.

4. Development of GA

The algorithm is developed based on GA for reaching our objective. Genetic algorithmis a random search technique for global optimization in a complex search space. It is

originally inspired by an analogy of the process of natural evolution. It is one of the

evolutionary search methods that can give optimal or near optimal solutions for the

combinatorial optimization problems such as travelling salesman problems, schedulingproblems, cell design problems and process planning problems. The main issues in

developing a genetic algorithm are chromosome representation, initialization of the

population, evaluation function, reproduction, crossover, mutation, and the selectionstrategy. Also, the genetic parameters such as population size (popsize), number of

generation (maxgen), probability of crossover (pc), and probability of mutation (pm) are

to be fixed before the implementation of GA.

4.1. Chromosome representation

Unlike many traditional optimisation techniques, GA works with a coding of thedecision variables themselves as chromosomes. Representation by coding a solution in

the form of strings (chromosomes) plays a key role in the development of a genetic

algorithm. Genetic algorithm usually starts with an initial set of solutions calledpopulation and the population at a given time is called a generation. Here we use integer

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

10/28

ForP

eerRev

iewOnly

numbers to represent the chromosome. Each gene represents a cell number and the

position of the gene in the chromosome represents the machine number. The length of the

chromosome represents the number of machine types considered. In this paper a gene canuse any number starting from one up to the number of machines since the number of cells

is not predetermined. Appearance of only 3 different integer numbers shows a three cell

solution. For example, a string 3 1 2 3 1 3 represents a solution of three cells for aproduction system with 6 machine types and the cell design contains the following

machines in each cell:

Cell 1: Machines 2, 5

Cell 2: Machine 3

Cell 3: Machines 1, 4, 6

Another possibility of a chromosome with the same machine grouping is 6 4 3 6 4 6.

In this chromosome there are three cells such as cells 3, 4 and 6 and their grouping is as

follows:

Cell 6: Machines 1, 4, 6

Cell 4: Machines 2, 5Cell 3: Machine 3

This configuration is same as the first configuration given above. This algorithm will

generate chromosome of the above types.

4.2. Initialisation of population

The initialisation step in a genetic algorithm is to create an initial population. The

initialisation process can be executed with either a randomly created population or a welladapted population. Here, the initialisation process is executed with a randomly generatedsolution space and the population size is taken to be 2.5 times (Pillai and Subbarao, 2008)

the length of the chromosome.

4.3. Fitness function

The purpose of fitness function is to compute the fitness of a candidate solution in the

population with respect to the design objectives. The fitness values are used to selectparent solutions to create the next generation of solutions. The specific form of fitness

function depends on the design objective being considered. The fitness of an individual

solution dictates the number of copies of that solution in the mating pool. The morecopies an individual receives, the greater is the probability that the characteristics will be

repeated in subsequent generations. In a GA, the fitness function is calculated for each

chromosome in the population with the intention of finding a chromosome withmaximum value. The objective of the cell formation problem discussed here is the

maximisation of grouping efficacy. So the fitness function is same as the function for

grouping efficacy.

Page 9 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

11/28

ForP

eerRev

iewOnly

4.4. Genetic operators

To create the next generation, a new set of chromosomes called offspring are createdby the execution of genetic operators such as reproduction, crossover and mutation.

Crossover acts as a chief operator for change while mutation acts as a secondary operator.

A generation of the genetic algorithm begins with reproduction. The reproduction

operator is used to select individuals from the current population to become parents of the

next generation. Parents are selected according to their fitness value and they aresubjected to crossover and mutation. Here, a method called remainder stochastic

sampling without replacement policy (Wicks and Reasor 1999, Pillai and Subbarao 2008)

is used for reproduction. The crossover operator creates new potential solutions by

exchanging a segment of the parent. In this way, child retains some of the features of theparent solution. The crossover is done with a probability called crossover probability.

Several crossover operators are available and two such operators are single-point and

two-point operators. The two-point crossover operator randomly generates two points

along the length of the chromosome, dividing each parent into three segments. The twochildren are created by exchanging second segment between the parents. In this paper

two-point cross over method is used. Mutation performs a secondary role in the workingof genetic algorithms. The purpose of this operator is to rejuvenate the search and extend

it to previously unexplored areas of the solution space. Mutation prevents the value of

any parameter from remaining untouched forever. Mutation operator protects against

such permanent loss. It is carried out with a low probability called probability ofmutation.

4.5. Selecting new population of solutions

After, genetic operators have been applied, new strings are formed and these stringsare called children or offspring. The poorly performing offspring are replaced in the newgeneration with a replacement strategy. The offspring are evaluated with respect to the

fitness function. The purpose of replacement strategy is to create generations of solutions

that, on an average, superior than the preceding generation. This is achieved by restricting

entry to only those children that are superior to members of the existing population to thenew population. The exception to this rule is that some less fit children are permitted to

be the part of the next generation. The purpose of seldom admitting less fit individual is

to help the algorithm to come out of the local optima.

4.6. Termination criteria

The genetic algorithm iterates, and as the process proceeds, the generation contains

chromosomes with higher fitness function values. Termination criterion is used to stop

the iteration. A single criterion or a set of criteria can be used to halt the geneticalgorithm. Here, two termination criteria are used together. The first termination criterion

monitors the improvement from generation to generation. If there is no improvement in

the best solution found for a pre-determined number of generations, the algorithm would

stop. The second termination criterion is concerned with maximum number of

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

12/28

ForP

eerRev

iewOnly

generations. Under this rule, the algorithm stops when a particular number of generations

have been reached.

4.7. Part assignment heuristic

In the present model part assignment carries great importance and it influences theobjective function. The value of the objective function is directly depending on it. The

assignment of machines to cells is carried out as per the GA and the part assignment to

these cells is carried out after machine assignment. The quality of the configurationdepends on the way in which a part is assigned to a cell. The part assignment heuristic is

developed with a view to reduce the number of exceptional elements and voids. The

heuristic is given below:

Assign a part to a cell in which it has maximum number of operations. If a tie exists, the part is assigned to a cell where the number of operations

(machines) not required by this particular part is minimum. And again if there is a tie, assign to any one of the cells in which previous tie issatisfied.

If there is no part assignment to a cell, select a part from the parts that requireoperation in the cell whose total number of operations is minimum.

5. Illustrative example

The algorithm is coded in MATLAB and is tested with 36 problems from literature.

An illustrative example demonstrates the effectiveness of the new approach. The inputmatrix of the example problem is shown in Table 2 and is taken from Chan and Milner

(1982).

The parameters used in GA which are set for all problems tested are given below.

Population size = 2.5 times length of chromosome

Probability of crossover = 0.85

Probability of mutation = 0.1

Probability of allowing weak solutions during replacement = 0.1

Number of weak solutions permitted = 1

The maximum number of generations (maxgen) and the pre-specified number of

iterations (PNI) which is used in the termination criteria is calculated using the followingequation:

maxgen= 6 MP

PNI= 2 MPwhereM Number of machines

P Number of parts

Page 11 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

13/28

ForP

eerRev

iewOnly

Table 2: Input matrix for illustrative example problem

Parts

Machines

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

1 1 1 1 1

2 1 1 1 1 1

3 1 1 1 14 1 1 1 1

5 1 1 1 1 1

6 1 1 1 1 1

7 1 1 1 1 1

8 1 1 1 1 1

9 1 1 1 1

10 1 1 1 1 1

0

10

20

30

40

50

60

70

80

90

100

1 3 5 10 15 20 25 50 75 100

Number of generations

Grouping

efficacy

Series1

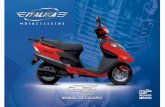

Figure 1 Solution convergence for the illustrative example problem

The block diagonal structure obtained for the problem, when the algorithm is used, is

shown in Table 3. Since this problem is a small problem and contains data which is easyto group, all methods in literature gave the same solution as in the proposed algorithm

and the grouping efficacy value of the configuration is 0.92. This solution is obtained

after 25 generations. Another problem of size 10 machines 20 parts from Tarique et al.

(2009) is also selected for testing where a grouping efficacy of one is possible and wealso got the best configuration using the proposed approach. This also proves the validity

of the algorithm and shows that it is able to provide a good grouping for the given

problem.

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

14/28

ForP

eerRev

iewOnly

Table 3: Block diagonal structure obtained for the illustrative example problem

Parts

Machines

3 5 8 13 15 1 4 6 9 14 2 7 10 11 12

2 1 1 1 1 1

5 1 1 1 1 1

8 1 1 1 1 13 1 1 1 1

4 1 1 1 1

6 1 1 1 1 1

9 1 1 1 1

1 1 1 1 1

7 1 1 1 1 1

10 1 1 1 1 1

6. Comparison of performance of the proposed algorithm with other

methods

The performance of the algorithm is tested with 36 problems selected from literature.The size of problems varied from 5 machines 7 parts to 40 machines 100 parts. The

solution obtained for these problems is compared with the previously reported results

based on the grouping efficacy. To ensure a good quality solution using the algorithm, itis run several times under the specified algorithm parameters. The number of runs is set

as 10. The factors which influence the quality of solution are related with the part

machine incidence matrix. A matrix may be ill-structured which means it cannot be easily

grouped with high efficacy. Another factor is the size of the problem. An ill-structuredlarge size problem requires large number of iterations (generation) and more number of

runs. The algorithm parameters and number of runs are fixed based on these factors.

The comparison of grouping efficacy obtained by our algorithm is carried out with the

grouping efficacy obtained by the following seven methods and selection of these

methods is based on the available data from literature.

ZODIAC (Chandrasekharan & Rajagopalan 1987),

GRAFICS (Srinivasan & Narendran 1991),

MST Clustering algorithm (Srinivasan 1994),GATSP Genetic algorithm (Cheng et al. 1998),

GP Genetic programming (Dimopoulos & Mort 2001),

EA Evolutionary algorithm (Goncalves and Resende 2004),HA Hybrid algorithm (Tarique et al. 2009).

The grouping efficacy of the above approaches for all the problems are taken fromGoncalves and Resende (2004) and Tarique et al. (2009). Table 4 shows the problem

sizes and their sources along with results. After solving the 36 problems, it is found that

better configuration based on grouping efficacy is obtained for majority of the problems

and the findings are given below.

Page 13 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

15/28

ForP

eerRev

iewOnly

Total number of problems 36

Number of problems with improvement 20 (55.5%)Maximum improvement in the value of GE 7.74 (for Problem 4)

Average improvement in the value of GE considering 20 problems 1.73

Number of problems with GE equal to the previously reported best values 12 (33.33%)Number of problems without improvement 4 (11.1%)

The GE value is less from the reported value by maximum of 3.62 (for Problem 35)

The GE value is less from the reported value on an average by 1.69 (This is only for 4problems while improvement is for 20 problems)

Number of problems for which the algorithm provides either better result or same result

as in the literature 32 (88.89%)

It is found that better results are obtained for problems irrespective of the problem

sizes. This is prominent in the case of ill-structured part machine incidence matrix where

the data is not easily groupable. For the ideal problems given in the literature, for which

grouping efficacy of one is possible, the proposed algorithm gives the perfect solution. Incase of ideal problems and problems which are very close to ideal, where grouping is

possible with very less number of exceptional elements and voids, majority of themethods are giving the best results. But those models are not performing well for ill-

structured input data. The proposed algorithm is performing reasonably well in this

aspect.

The part assignment rule plays an important role in this algorithm for getting better

solutions than the previously reported results in terms of grouping efficacy. This is

because it is trying to reduce both exceptional elements and voids. The less efficacy valuefor four problems may also be because of the part assignment rule, where improved

efficacy might have been possible by a different part assignment rule.

Table 5 shows the input matrix and Table 6 shows the solution for the problem

number 5 in which an improved solution is obtained. The problem number 5 contains

only 7 machines and 11 parts which is a very small size problem as far as a cell design

problem is concerned. (A better solution using the proposed algorithm, than that of theearlier methods, is obtained for this problem. All the four methods of literature have

provided the same value for grouping efficacy whereas the proposed method suggested a

better value for grouping efficacy. It is possible to find similar result in the case ofproblem number 9. In this problem, the result of six methods is available and all these

methods provided the same value for grouping efficacy whereas the proposed method

provides better value. These types of performance for small problems show theeffectiveness of the proposed algorithm.) Based on this analysis, we can say that the

algorithm is performing better than the previous approaches.

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

16/28

ForP

eerRev

iewOnly

Table 4: Comparison of grouping efficacy of the proposed algorithm with other methodsProblem Size

(MP)

ZODIAC GRAPHICS MST GATSP GP EA HA PROPOSED

MODEL

1 57 73.68 73.68 - - - 73.68 73.68 73.68

2 518 77.36 - - 77.36 79.59 79.59 79.59

3 68 76.92 - - 76.92 76.92 76.92 76.92

4 711 39.13 53.12 - 46.88 - 53.13 53.13 60.875 711 70.37 - - 70.37 - 70.37 70.37 70.83

6 812 68.3 68.3 - - - 68.3 68.3 70.45

7 820 58.33 58.13 58.72 58.33 58.72 58.72 58.72 58.72

8 820 85.24 85.24 85.24 85.24 85.24 85.24

9 1010 70.59 70.59 70.59 70.59 70.59 70.59 75

10 1015 92.00 92.00 92.00 92.00 92.00 92.00 92.00

11 1215 - - - - - 86.67 86.67 86.67

12 1020 - - - - - - 100 100

13 1423 64.36 64.36 64.36 - - 60.86 70.83 73.13

14 1424 65.55 65.55 67.44 69.33 70.51 71.83

15 1624 32.09 45.52 48.70 - - 52.58 51.96 53.13

16 1630 67.83 67.83 67.83 - - 67.83 67.83 69.23

17 1643 53.76 54.39 54.44 53.89 - 54.86 54.86 55.92

18 1824 41.84 48.91 44.20 - - 54.46 54.95 57.73

19 2020 21.63 38.26 - 37.12 42.96 43.45 42.96

20 2023 38.66 49.36 43.01 46.62 49 49.65 49.65 50.81

21 2035 75.14 75.14 75.14 75.28 76.22 76.14 77.16

22 2035 51.13 - - 55.14 - 58.07 58.38 58.89

23 2440 100 100 100 100 100 100 100 100

24 2440 85.11 85.11 85.11 85.11 - 85.11 85.11 85.11

25 2440 73.51 73.51 73.51 73.03 73.51 73.51 73.51 73.51

26 2440 20.42 43.27 51.81 49.37 - 51.97 52.5 53.29

27 2440 18.23 44.51 44.72 44.67 - 47.06 46.84 48.95

28 2440 17.61 41.67 44.17 42.50 - 44.87 44.85 46.21

29 2727 52.14 41.37 51 - - 54.27 54.31 53.66

30 2846 33.01 32.86 40 - - 44.62 46.43 46.84

31 3041 30.46 55.43 55.29 53.80 - 58.48 60.74 62.77

32 3050 46.06 56.32 58.70 56.61 - 59.66 59.66 59.77

33 3050 21.11 47.96 46.30 45.93 - 50.51 50.51 50.83

34 3090 32.73 39.41 40.05 - - 42.64 44.67 42.64

35 3753 52.21 52.21 - - - 56.42 59.60 55.98

36 40100 83.66 83.92 83.92 84.03 84.03 84.03 84.03 84.03

Page 15 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

17/28

ForP

eerRev

iewOnly

Data sets for problem numbers 1-6, 9-11, 13-16, 18-26, 28, 29-35 are taken fromGonclaves and Rescende (2004) and these problems are originally referred by them from

research articles published during 1972-1992. Other data sets are taken from

Problem-7- Chandrasekharan and Rajagopalan (1986a)

Problem-8-Chandrasekharan and Rajagopalan (1986b)

Problem-12-Tarique et al.(2009)Problem-17-King (1980)

Problem-27-Chandrasekharan and Rajagopalan (1989)Problem-36-Chandrasekharan and Rajagopalan (1987)Note: Shaded region indicates problems with improved GE or previously reported best GE

Table 5: Input matrix (problem 5)

Table 6: Output matrix (problem 5)

6.1 Performance of proposed algorithm

It may not be possible to improve the performance of problems which attained

maximum grouping efficacy. If two or more methods of latest generation provide the

same result then we can assume that the chance of getting further improvement is less.That is, these problems have attained the highest grouping efficacy. For certain problems,

the grouping efficacy is 100, which means that further improvement is not possible. That

is, for 12 problems the proposed method provided good result (see Table 7 given below).

Parts

Machine

1 2 3 4 5 6 7 8 9 10 11

1 0 1 1 0 0 0 1 0 0 0 0

2 1 0 0 0 1 0 0 0 0 0 13 0 0 0 0 0 0 0 0 0 1 14 1 0 1 0 0 1 0 0 0 0 05 0 0 0 0 1 0 0 1 0 0 0

6 1 0 0 1 0 0 0 1 1 1 0

7 0 0 1 1 0 1 1 0 1 0 0

Parts

Machines

2 7 11 3 6 5 1 4 8 9 10

1 1 1 0 1 0 0 0 0 0 0 0

2 0 0 1 0 0 1 1 0 0 0 03 0 0 1 0 0 0 0 0 0 0 1

4 0 0 0 1 1 0 1 0 0 0 07 0 1 0 1 1 0 0 1 0 1 0

5 0 0 0 0 0 1 0 0 1 0 0

6 0 0 0 0 0 0 1 1 1 1 1

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

18/28

ForP

eerRev

iewOnly

So, we can say that out of 36 problems, the proposed method provide good result for 32

(20 + 12) problems.

Table 7: Analysis of problems for which the result of proposed method is the same as the

methods in the literature

Problem

Number

Number of

methodsapplied

Number of

methods thatgave best

result

Remarks

1 4 4

2 4 2

3 4 4

7 7 4

8 5 5

10 6 6

11 2 2

12 1 1 Obtained maximum possiblegrouping efficacy value (100)

23 7 7 Obtained maximum possiblegrouping efficacy value (100)

24 6 6

25 7 6

It may be noted that the best performed method in the literature is of Tarique et al.

(2009). It provides better result for only 11 (31.42%) problems out of 35 and for 20problems it has the same result as in the literature. The proposed method provides better

result for 55.56% of problems. The comparison of result of proposed method with the

result of 7 methods of literature includes Tarique et al. (2009). The average improvement

in the value of result in the case of Tarique et al. (2009) is 1.71 whereas for the proposedmethod it is 1.73 even after considering the result of Tarique et al. (2009). It may be

noted that as better methods evolve, the improvement magnitude decreases. However, the

proposed method could give better improvement compared to the latest methodsavailable in the literature.

7. Extension of the algorithm for alternative routes.

The proposed cell formation algorithm is extended to consider alternative routes

existing for certain parts. The extension is achieved by applying a simple modification to

the previous algorithm. When alternative routes are considered, more than onecombination of machines are available for carrying out different operations of a part. For

example Table 8 shows a part machine incidence matrix considering alternative routes. Itis a cell formation problem with 8 machines and 20 parts and certain parts have

alternative routes. Part number 1 which requires two processing operations has two

alternative routes, route 1 and route 2. The two operations of part 1 can be done usingmachine 4 and machine 6 or with machine 5 and machine 6. These routes are shown in

Page 17 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

19/28

ForP

eerRev

iewOnly

the first two columns of the part machine incidence matrix given in Table 8. As a result

of the alternative routes, 20 parts have 27 routes which are given in Table 8.

Table 8: Part machine incidence matrix showing alternative routesParts

Machines

P1

1

P1

2

P2

1

P3

1

P4

1

P4

2

P4

3

P5

1

P6

1

P7

1

P8

1

P9

1

P

10

1

P

10

2

P

11

1

P

11

2

P

12

1

P

13

1

P

14

1

P

14

2

P

15

1

P

16

1

P

17

1

P

18

1

P

19

1

P

20

1

P

20

2S.

No.1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

M1 0 0 1 1 0 1 0 0 0 0 1 1 0 1 1 0 0 1 1 1 1 1 1 0 1 0 0

M2 0 0 0 1 0 0 1 0 1 1 0 0 0 0 0 1 0 0 1 1 0 0 0 1 0 1 1

M3 0 0 1 0 0 0 0 0 0 0 1 1 0 0 1 1 0 1 1 0 1 1 1 0 1 0 1

M4 1 0 0 1 1 1 0 0 1 1 0 0 1 1 0 0 0 0 0 0 0 0 0 0 0 1 1

M5 0 1 0 0 1 0 1 1 1 0 0 0 1 1 0 0 1 0 0 1 0 0 1 0 0 0 0

M6 1 1 0 0 0 0 0 1 0 1 0 1 1 0 0 0 1 0 0 0 0 0 0 0 0 1 1

M7 0 0 0 1 1 1 1 0 1 1 0 0 0 0 1 1 1 0 0 0 0 0 0 1 0 1 1

M8 0 0 0 1 1 1 1 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 0

7.1. Algorithm for alternative routes

The algorithm is developed with a view to obtain a configuration with maximumgrouping efficacy considering multiple routes. That is, the algorithm identifies a route for

the items with alternative routes such that the resultant solution has the better grouping

efficacy. The algorithm is described below.

Step 1: Consider an alternative route available to a part as a route of another individual

part. In case of a part with three routes, they are considered as the route of threeindividual parts. Now, the problem considered assumes more number of parts

than the original number of parts. That is, the problem situation given in Table 8

is equivalent to 27 parts instead of 20.Step 2: Apply the algorithm given in Section 3 to the modified incidence matrix.

Step 3: Now, the solution obtained contains parts corresponding to alternative routes. At

this stage consider them as alternative routes of a single part.

Step 4: Consider the parts with alternative routes one by one. Examine the sum of numberof voids and exceptional elements created by each route for such a part. Select

the route with least sum for each part and eliminate other routes.

Step 4a: If the sum of exceptional elements and voids are equal for two routes, then theroute with less number of exceptional elements has to be selected.

The steps 4 and 4a will ensure maximum grouping efficacy for the selected configuration.

7.2 An example problem

The problem situation given in Table 8 is considered for explaining the working of the

algorithm. The actual size of the problem is 8 machines 20 parts. After applying step 1,

it is equivalent to an 8 machines 27 parts problem. Then the algorithm given in Section3 is applied and the resultant configuration is shown in Table 9, which has maximum

efficacy. Now, consider this result as the solution for an 8 machines 20 parts problem

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

20/28

ForP

eerRev

iewOnly

with alternative routes. The extra seven routes are eliminated through the procedure given

in step 4 and step 4a of the extended algorithm and the final configuration obtained is

given in Table 10. The grouping efficacy of the final solution is 80.54.

Table 9: Solution after step 2 of the algorithm for alternative routes

Parts

Machines

Sl

No.

3 11 12 14 15 18 19 20 21 22 23 25 27 4 5 6 7 9 10 16 24 26 1 2 8 13 17

P

2

1

P

8

1

P

9

1

P

10

2

P

11

1

P

13

1

P

14

1

P

14

2

P

15

1

P

16

1

P

17

1

P

19

1

P

20

2

P

3

1

P

4

1

P

4

2

P

4

3

P

6

1

P

7

1

P

11

2

P

18

1

P

20

1

P

1

1

P

1

2

P

5

1

P

10

1

P

12

1

M1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

M3 1 1 1 1 1 1 1 1 1 1 1 1

M2 1 1 1 1 1 1 1 1 1 1

M4 1 1 1 1 1 1 1 1 1 1

M7 1 1 1 1 1 1 1 1 1 1 1 1

M8 1 1 1 1 1 1 1

M5 1 1 1 1 1 1 1 1 1

M6 1 1 1 1 1 1 1 1 1

Table 10: Final solution using the algorithm for alternative routesParts

Machines

P

2

1

P

8

1

P

9

1

P

11

1

P

13

1

P

14

1

P

15

1

P

16

1

P

17

1

P

19

1

P

3

1

P

4

3

P

6

1

P

7

1

P

18

1

P

20

1

P

1

2

P

5

1

P

10

1

P

12

1

M1 1 1 1 1 1 1 1 1 1 1 1

M3 1 1 1 1 1 1 1 1 1 1

M2 1 1 1 1 1 1 1

M4 1 1 1 1 1 1

M7 1 1 1 1 1 1 1 1

M8 1 1 1 1 1M5 1 1 1 1 1 1

M6 1 1 1 1 1 1 1

8. Conclusion

The new approach proposed in this paper gives an efficient algorithm for part/machine

grouping with the part machine incidence matrix as input. The approach relies on the

algorithm for cell formation where genetic algorithm principles are employed foroptimization. An efficient customized rule for part assignment is incorporated into the

algorithm which has a high impact on the objective of the algorithm and this objective is

the maximisation of grouping efficacy. The algorithm identifies the best grouping (cellsand part families) for the given part machine incidence matrix and number of cells/or partfamilies is not an input for the algorithm.

The example problems solved using the algorithm show the appropriateness andefficiency of the algorithm. A comparison of result obtained for 36 problems using the

proposed algorithm with other seven methods indicates that for 55.5% of problems the

result shows improved grouping efficacy and for 33.3% of problems the grouping

Page 19 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

21/28

ForP

eerRev

iewOnly

efficacy is same as the previously reported best results. So, the algorithm is performing

better than the seven methods. Thus, the algorithm is suitable for identification of

machine cells and part families more effectively compared to the models available in theliterature. Further, this algorithm is extended to consider alternative routes. The extended

algorithm is able to incorporate alternative routes for developing a good configuration

which maximise the grouping efficacy. The algorithm for alternative routes identifies aroute that maximise the grouping efficacy.

A future scope of this work can be a better part assignment rule which may improvethe quality of solutions specifically for the four problems given in Table 4 without

affecting the other 32. The algorithm can be further modified by incorporating operation

sequence data of parts with suitable efficiency measure.

Acknowledgment

The authors are thankfully acknowledging the constructive suggestions of reviewers

which helped to improve the manuscript.

References

Adenso-Diaz, B. and Lozano, S., 2008. A model for the design of dedicated

manufacturing cells.International Journal of Production Research, 46 (2), 301319.

Adil, G.K., Rajamani, D. and Strong, D., 1997. Assignment allocation and simulatedannealing algorithms for cell formation.IIE Transactions, 29, 5367.

Ameli, M.S.J. and Arkat, J., 2008. Cell formation with alternative process routings and

machine reliability consideration. International Journal of Advanced ManufacturingTechnology, 35, 761768.

Arkat, J., Saidi, M. and Abbasi, B., 2007. Applying simulated annealing to cellular

manufacturing system design.Journal of Advanced Manufacturing Technology, 32, 531536.

Askin, R. and Chu, K., 1990. A graph partitioning procedure for machine assignment andcell formation in group technology.International Journal of Production Research, 28 (8),

15551572.

Cao, D., Defersha, M. and Chen, M., 2009. Grouping operations in cellular

manufacturing considering alternative routings and the impact of run length on product

quality.International Journal of Production Research, 47 (4), 9891013.

Caux, C., Bruniaux, R. and Pierreval, H., 2000. Cell formation with alternative processplans and machine capacity constraints: a new combined approach. International Journal

of Production Economics, 64, 279284.

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

22/28

ForP

eerRev

iewOnly

Chan, H. and Milner, D., 1982. Direct clustering algorithm for group formation in

cellular manufacturing.Journal of Manufacturing Systems, 1 (1), 6567.

Chandrasekharan, M.P. and Rajagopalan, R., 1986a. MODROC, An extension of rank

order clustering for group technology. International Journal of Production Research, 24

(5), 12211233.

Chandrasekharan, M. P. and Rajagopalan, R., 1986b. An ideal seed non-hierarchical

clustering algorithm for cellular manufacturing. International Journal of ProductionResearch, 24 (2), 451464.

Chandrasekharan, M.P., and Rajagopalan, R., 1987. ZODIACAn algorithm forconcurrent formation of part families and machine cells. International Journal ofProduction Research, 25 (6), 835850.

Chandrasekharan, M.P. and Rajagopalan, R., 1989. GROUPABILITY: Analysis of theproperties of binary data matrices for group technology. International Journal of

Production Research,27 (6), 10351052.

Cheng, C.H., Gupta, Y.P., Lee, W.H. and Wong, K.F., 1998. A TSP-based heuristic for

forming machine groups and part families.International Journal of Production Research,

36 (5), 13251337.

Choobineh, F., 1988. A framework for the design of cellular manufacturing systems.

International Journal of Production Research, 26 (7), 11611172.

Diaz, J.A., Luna, D. and Luna, R., 2012. GRASP heuristic for the manufacturing cell

formation problem. TOP, 20, 3, 679706.

Dimopoulos, C. and Mort, N., 2001. A hierarchical clustering methodology based on

genetic programming for the solution of simple cell-formation problems. International

Journal of Production Research, 39 (1), 119.

Goncalves, J.F. and Resende, M.G., 2004. An evolutionary algorithm for manufacturingcell formation. Computers & Industrial Engineering, 47, 247273.

Islier, A., 2005. Group technology by an ant system algorithm. International Journal of

Production Research,43 (5), 913932.

Kazerooni, M., Luong, H.S. and Abhary, K., 1997. A genetic algorithm based cell design

considering alternative routing. Computer Integrated Manufacturing Systems,10 (2), 93

107.

King, J.R., 1980. Machine-component grouping in production flow analysis: an approach

using rank order clustering algorithm, International Journal of Production Research, 18

(2), 213232.

Page 21 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

23/28

ForP

eerRev

iewOnly

Kumar, K.R. and Chandrasekharan, M.P., 1990. Grouping efficacy: A quantitative

criterion for goodness of block diagonal forms of binary matrices in group technology.International Journal of Production Research, 28 (2), 233243.

Kumar, K. R., & Vannelli, A., 1987. Strategic subcontracting for efficient disaggregatedmanufacturing.International Journal of Production Research, 25 (12), 17151728.

Kusiak, A. and Chow, W., 1987. Efficient solving of the group technology problem.

Journal of Manufacturing Systems, 6 (2), 117124.

Lin, S.W. and Ying, K.C., 2012. Scheduling a bi-criteria flowshop manufacturing cell

with sequence-dependent family setup times. European Journal of IndustrialEngineering , 6 (4), 474496.

Mak, K.L., Wong, Y.S. and Wang, X.X., 2000. An adaptive genetic algorithm for

manufacturing cell formation. International journal of advanced manufacturingtechnology,16, 491497.

McCormick, W.T., Schweitzer, P.J. and White, T.W., 1972. Problem decomposition data

reorganization by a clustering technique. Operation Research, 20 (5), 9931009.

Nouri, H. and Hong, T.S., 2012. A bacteria foraging algorithm based cell formationconsidering operation time,Journal of manufacturing systems, 31, 3, 326 336.

Nouri, H. and Hong, T.S., 2013. Development of bacteria foraging optimizationalgorithm for cell formation in cellular manufacturing system considering cell load

variations,Journal of manufacturing systems, 32, 1, 20 31.

Onwubolu, G.C. and Mutingi, M., 2001. A genetic algorithm approach to cellular

manufacturing systems. Computer & Industrial engineering,39, 125144.

Pandian, R.S. and Mahapatra, S.S., 2008. Manufacturing cell formation with productiondata using neural networks. Computers & Industrial Engineering, 56, 13401347.

Pillai, V.M. and Subbarao, K.A., 2008. Robust cellular manufacturing system design fordynamic part population using a genetic algorithm. International Journal of Production

Research, 46 (1), 51915210.

Rogers, D.F. and Kulkarni, S.S., 2005. Optimal bivariate clustering and a genetic

algorithm with an application in cellular. European Journal of Operational Research,

160, 423444.

Sarac, T., and Ozcelik, F., 2012. A genetic algorithm with proper parameters for

manufacturing cell formation problems. Journal of Intelligent Manufacturing, 23, 4,

10471061.

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

24/28

ForP

eerRev

iewOnly

Sayadi, M.K., Hafezalkotob, A. and Naini, S.G.J., 2013. Firefly-inspired algorithm for

discrete optimization problems: An application to manufacturing cell formation, JJournal of manufacturing systems, 32, 1, 2013, 78-84.

Seifoddini, H., 1989. Single linkage versus average linkage clustering in machine cellsformation applications. Computers and Industrial Engineering, 16 (3), 419426.

Shanker, R. and Vrat, P., 1999. Some design issues in cellular manufacturing using thefuzzy programming approach. International Journal of Production Research, 37 (11),

2545 2563.

Soto, R., Kjellerstrand, H., Duran, O., Crawford, B., Monfroy, E. and Paredes, F., 2012.Cell formation in group technology using constraint programming and Boolean

satisfiability.Expert Systems with Applications, 39, 13, 1142311427.

Srinivasan, G., 1994. A clustering algorithm for machine cell formation in grouptechnology using minimum spanning trees. International Journal of Production

Research, 32, 21492158.

Srinivasan, G., and Narendran, T.T., 1991. GRAFICS-A non-hierarchical clustering-

algorithm for group technology. International Journal of Production Research, 29 (3),

463478.

Srinivasan, G., Narendran, T.T, and Mahadevan, B., 1990. An assignment model for the

part-families problem in group technology. International Journal of ProductionResearch, 28 (l), 145152.

Tarique, A., Hussain, I. and Ghafoor, A., 2009. A hybrid genetic algorithm for machine-part grouping. Computers & Industrial Engineering, 56, 347356.

Tavakkoli-Moghaddam, R., Aryanezhad, M.B., Safaei, N. and Azaron , A., 2005. Solving

a dynamic cell formation problem using metaheuristics. Applied Mathematics andComputation, 170, 761780.

Wicks, E.M. and Reasor, R.J., 1999. Designing cellular manufacturing systems with

dynamic part Populations. IIE Transactions, 31, 1120.

Won, Y. and Currie, K.R., 2007. Fuzzy ART/RRR-RSS: a two-phase neural network

algorithm for part-machine grouping in cellular manufacturing. International Journal of

Production Research, 45 (9), 20732104.

Wu, X., Chu, C.H., Wang, Y. and Yan, W., 2006. Concurrent design of cellular

manufacturing systems: a genetic algorithm approach. International Journal of

Production Research, 44 (6), 12171241.

Page 23 of 26

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

25/28

ForP

eerRev

iewOnly

Wu, X., Chu, C.H, Wang, Y. and Yan, W., 2007. A genetic algorithm for cellular

manufacturing design and layout,European Journal of Operational Research,181, 156167.

Yasuda, K. and Yin, Y., 2001. A dissimilarity measure for solving the cell formationproblem in cellular manufacturing. Computers and Industrial Engineering, 39 (1-2), 1

17.

Zolfaghari, S. and Liang, M., 1998. Machine cell/part family formation considering

processing times and machine capacities: a simulated annealing approach. Computers

and Industrial Engineering, 34, 813823.

Zolfaghari, S. and Liang, M., 2002. Comparative study of simulated annealing, genetic

algorithms and tabu search for solving binary and comprehensive machine-grouping

problems.International Journal of Production Research, 40 (9), 21412158.

Pag

http://mc.manuscriptcentral.com/tprs Email: [email protected]

International Journal of Production Research

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-

5/25/2018 A Revisar IJPR Septiembre 2

26/28

ForP

eerRev

iewOnly

Response to Comments of Reviewer(s)

Reviewer comment

A set of recent literature on "cell formation problem with metaheuristics or evolutive

optimization algorithms" is needed. Just one reference is given from 2009. We suggest that theauthors need to review last 3 or 4 years.

For instance:

Diaz et al. (2012) DI 10.1007/s11750-010-0159-3

Lin, SW and Ying, KC (2011) DOI: 10.1504/EJIE.2012.047666

Tavakkoli-Moghaddam, R et al. (DOI: 10.1016/j.amc.2004.12.021

Sarac, Tugba; Ozcelik, Feristah (2012) DOI: 10.1007/s10845-010-0446-8

R.Soto, et alli. (2012) DOI: 10.1016/j.eswa.2012.04.020

Response to Comment

Recent literature using meta-heuristics or evolutionary optimization algorithms are included (up

to 2012 and 2013). All papers suggested by the reviewer are also included. New methods of

evolutionary algorithms like Bacteria foraging algorithms, Firefly-inspired algorithm, etc. are