201307 Drillingcontractor Pemex Deepwater Gom Subsalt Drilling

-

Upload

jose-antonio-olvera-jimenez -

Category

Documents

-

view

220 -

download

0

Transcript of 201307 Drillingcontractor Pemex Deepwater Gom Subsalt Drilling

-

8/10/2019 201307 Drillingcontractor Pemex Deepwater Gom Subsalt Drilling

1/5

L L D R I L L I N G A L L C O M P L E T I O N S A L L T H E T I M E

Dr i l l i n gC O N T R A C T O R

OFFICIAL MAGAZINE OF THE INTERNATIONAL ASSOCIATION OF DRILLING CONTRACTORS

J U LY / AU G U S T 2 0 1 3 W W W. D R I L L I N G C O N T R A C TO R . O RG

REGIONAL FOCUS:EUROPE

UK, Norway seeing record-high spendingas operators focus on optimizing recovery,

maximizing smaller-prize discoveries p.122

DATA DELIVERY MWD/LWD advances push telemetr y rateshigher, expand capabilities in horizontal, HPHT,

deepwater environments p.62

From assurance processes to capping toolkits to BOPmaintenance, multitude of initiatives are under way

to enhance industrys operational integrity p.18

-

8/10/2019 201307 Drillingcontractor Pemex Deepwater Gom Subsalt Drilling

2/5

Innovating While Drilling

R E P R I N T E D F R O M T H E J U LY / A U G U S T I S S U E O F D R I L L I N G CONTRACTOR

As industry increasingly ventures

into deeper waters characterized

by complex reservoirs, the inte-

gration of upfront planning, risk manage-

ment, workflow strategies and technolo-

gies that provide operational reliability

are paramount. This trend has become

evident in regions such as the Gulf ofMexico (GOM), where subsalt formations

holding significant reserves are attract-

ing operators. Despite risks of wellbore

instability and lost circulation, technol-

ogy has made exploration and develop-

ment of these fields economically viable.

For its initial foray into the deepwa-

ter, subsalt arena, Petrleos Mexicanos

(PEMEX) opted to avoid the risk of drill-

ing directly through the salt dome in

an exploratory well, choosing instead a

more conservative drilling route around

and underneath the salt flank. While

less difficult in some respects, the option

posed its own challenges, such as the

need to design a more deviated trajectory

and drill through the sheared, or rubble,

zone commonly found under or adjacent

to salt bodies, where there is a risk of

becoming stuck.

The complexities of the project wereaddressed using a collaborative and

integrated approach. The eight-month

operation involved extensive upfront

planning; pre-drill, 3D geomechanical

modeling and simulation; contingency

planning for multiple well sections;

importing technology and hardware to

the well site; real-time data surveillance;

new technologies, such as seismic-

vision-while-drilling, to guide the well

under the salts, and the design of a long

bottomhole assembly (BHA) to reach the

target zone.

Real-time drilling

optimization key

to pre-drill modeling,

execution for complex

exploratory well

BYVICTORGERARDOVALLEJO, PEMEX;

MANUELE. TORRESANDLUISFELIPE

GONZALEZ, SCHLUMBERGER

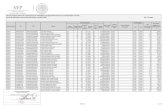

Cap Rock

Rubble zone

Salt

Vel. Int_Subcubo RTMviVel. Int_Pseudo 3_RTMviVel. Int_Pseudo 4_RTMviVel. Int_Pseudo 1_RTMviVel. Int_Pseudo 2_RTMvi

Vel. Int_Subcubo RTMvi (m/s)

For PEMEXs foray into the deep-

water, subsalt arena, the company

planned a drilling route around the

Kabilil-1 subsalt well in the Gulf of

Mexico that incorporated a devi-

ated trajectory through a rubble

zone. The idea was to avoid the risk

of drilling through the salt dome in

an exploratory well.

Integrated approach

delivers GOM subsaltwell for PEMEX

-

8/10/2019 201307 Drillingcontractor Pemex Deepwater Gom Subsalt Drilling

3/5

Innovating While Drilling

R E P R I N T E D F R O M T H E J U L Y / A U G U S T I S S U E O F D R I L L I N G C O N T R A C T O R

The well was drilled with a third-gener-

ation semisubmersible in 94 days, reach-

ing a total depth of 5,350 meters (17,552

ft). The well included a 20-in. riserless

section, an 8 -in. open-hole section and

several sections that required multiple

casing scenarios due to the need for con-

tingencies to isolate problematic zonesand manage the narrow mud weight drill-

ing window between pore pressure and

fracture pressure.

The real-time monitoring of drilling

parameters and geomechanics service

was also introduced during this project;

it is a workflow process executed by

Schlumberger that ties together various

operational elements to mitigate risk.

The Kabilil-1 well was located in a

Tertiary formation of the Mexican GOM,

about 105.5 km (66 miles) northeast of

Coatzacoalcos, Veracruz, and 253 km(157 miles) northwest of Ciudad del

Carmen, Campeche, in a water depth

of 739 meters (2,425 ft). The well exhib-

ited an overhang feature covered by a

large eroded area and was located in a

structural trap on the eastern side of a

large anticline that had been deformed

by the effects of salt intrusion. The target

reservoir held turbidites patterned in

upwardly-thickening sections and amal-

gamated turbidites in channels where

sandstone and mudstone deposits had

led to an increase in elevation. Analysisindicated complex geology and sediments

adjacent to the salt.

3D GEOMECHANICAL

MODELING

In performing the initial risk assess-

ment for determining the optimum drill-

ing strategy, the technical teams pre-

pared a pre-drilling analysis that includ-

ed a finite-element numerical model and

a 3D mechanical earth modeling simula-

tor to predict the effects of the initial

in-situ stresses, measure the influence ofsalt intrusion and induced pressures and

earth stresses, and determine adequate

mud weights.

The 3D simulator conducted a stress/

strain analysis on a small section of the

sedimentary layers and the salt bodies.

Element models were taken from geo-

logic structure maps using the VISAGE

modeling software. The methodology

incorporated data from one-dimensional

mechanical earth models of several off-

set wells, property propagations using

3D seismic data and 3D finite element

mechanical earth modeling. It also mea-

sured stresses and pore pressures to

analyze wellbore stability along the pro-

posed well path.

The stress/strain analysis showed sig-

nificant variations in stress orientation

and magnitude around the salt dome. Astress profile along the planned well path

indicated an obvious increase in horizon-

tal compressive stresses resulting from

salt perturbations, as well as an increase

in shear stresses at 1,500 meters to 2,100

meters (4,921 ft to 6,890 ft) total vertical

depth, where shear stresses peaked. That

depth range coincided with a decrease of

vertical effective stress, indicating a high

deformation zone with a fault at 2,100

meters (6,890 ft).

The analysis also suggested stress

in surrounding sediments located morethan 1.5 km (1 mile) from the salt dome.

The 3D analysis of the mud weight win-

dow resulted in a plan with adequate

mud weights.

REAL-TIME MONITORING

OF DRILLING PARAMETERS

AND GEOMECHANICS

Key to the validation of the pre-drill

modeling and plan execution was the

real-time drilling optimization program.

The program requires teamwork between

the operator and service company to

address drilling risks, classified with a

color-coded system, such as low rates

of penetration, caved hole sections, well

influxes, mud losses and BHA vibrations.

It also provides a structured methodol-

ogy for communication, where events are

communicated from drilling optimizationengineers and real-time geomechanics to

decision-makers. For the Kabilil-1 well,

the communication scenario included

members of various disciplines (drilling

engineers, geoscientists, rig crew mem-

bers) from both companies.

Working in tandem with this program

was the PEMEX multidisciplinary work-

flow program VCD-SE (Visualization,

Conceptualization Development), also

referred to as Front End Loading. It

identifies the most critical risks during

the pre-drill planning phase by building3D and 1D mechanical earth models with

data from offset wells.

The geo-modeling process produced

several findings that served as the basis

for developing the final drilling plan.

Among them was the determination that

drilling close to the salt dome would

result in higher-than-expected collapse

pressures at the end of the riserless sec-

tion. This required optimizing the drill-

ing fluid by combining seawater with

weighted bentonite mud. Other hazards

included:

Analysis using a fnite-element numerical model and 3D mechanical earth

modeling simulator indicated signifcant variations in stress orientation and

magnitude around the salt dome. The simulator also suggested stress in

surrounding sediments located more than 1.5 km from the salt dome.

Pore Pressure Cube

KABILIL-1KABILIL-1

KABILIL-1KABILIL-1

KABILIL-1

Pore Pressure(kPa)

1.1437e+005

85777.0

57185.0

28593.0

1.0000

-15000.0

-6250.0

-27500.0

-48750.0

-70000.0

15000.0-714.29.0-16429.0-32143.0-47859.0-63571.0

-79286.0-95000.0

Effective Vertical Stress(kPa)

Negativevalues =Compression

Positivevalues =Tension

East Effective Stress(kPa)

Negativevalues =Compression

Positivevalues =Tension

North-South Effective Stress(kPa)

Negativevalues =Compression

Positivevalues =Tension

North

North

North

11.7 km

(65 cells)

6 km

(127 cells)

10.6 km

(59 cells)

North

North

E-W Effective Stress Cube

Vertical Effective Stress Cube

N-S Effective Stress Cube

Visage Mesh

-15000.0

-6250.0

-27500.0

-48750.0

-70000.0

-

8/10/2019 201307 Drillingcontractor Pemex Deepwater Gom Subsalt Drilling

4/5

Innovating While Drilling

R E P R I N T E D F R O M T H E J U LY / A U G U S T I S S U E O F D R I L L I N G CONTRACTOR

Shear stresses from the salt body

influence would result in narrower mud

weight windows for the 20-in. and 16-in.

open-hole sections; The presence of a reverse fault in

the open-hole sections posed the risk of

well losses;

Because the surface seismic model

contained uncertainties regarding the

precise location of the salt flank, the

planned well trajectory would require

precise navigation around the salt body.

Drilling into the salt dome would add

complexity to the operation;

The well design would need to be

optimized using unconventional cas-

ing (16-in. and 13 5/8-in. outer diameter

strings) to allow two additional contin-

gency casing strings (11 -in. and 5

-in.) for the interval with the narrow

drilling windows; Special underreaming BHA designs

were required to perform simultaneous

hole opening without the need for extra

drilling runs. Due to the hole-opening

initiatives, the BHAs would need to be

stabilized with drilling simulators to

minimize drilling vibrations that could

destroy downhole tools and damage the

borehole with BHA shocks;

Continual equivalent circulating den-

sity would be required to minimize mud

losses due to drilling-induced fractures

or during the well cement process. A

foam cement system would be required

to optimize cement placement;

Intermediate casing strings would

need to be set at the appropriate depthto improve the drilling performance of

the subsequent well sections, segregate

the overpressure intervals induced by

salt intrusion and separate incompatible

formations.

In transitioning from the pre-drill plan-

ning stage to the execution phase, a drill-

ing and engineering operations plan with

a course of action for each well risk was

created. Using the real-time drilling opti-

mization process, offshore engineers and

onshore geomechanics engineers worked

together to update prediction models.

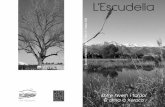

845 m

Liner 16 in

Casing 13 5 8in

Hole 28 in

Hole 17 in 20 in

Water depth=739 m

Air gap=25 m

1,524 m

2,125 m

3,346 m

4,563 m

Casing 20 in

Landing sub at 1,200 m

Pilot Hole 14 in 17 in

Hole 12 in 14 in

Conductor 36 in

Liner 9 5 8in97 8in

Pills 1.06 g/cm 3

Synthetic Mud1.211.33 g/cm 3

Sea Water andViscous Pills

Pump and Dump

1.051.25 g/cm 3

Synthetic Mud1.77 g/cm 3

Synthetic Mud

1.371.53 g/cm 3

Synthetic Mud1.571.89 g/cm3

Open Hole 8 in

Vetco Gray Subsea Wellhead System 18 in15 M Model DMS-700

Rotary table=763 m

Top well head 18 in=758.75 mTop housing 36 in=759.6 m

Top mud mat=762.7 m

TD=5,350 m

REAL

850 m

Liner 16 in

Casing 13 5 8in

Hole 28 in

Hole 17 in 20 in

Water depth= 740 m

Air gap=25 m

1,500 m

2,200 m

3,000 m

3,400 m

4,600 m

4,450 m

Casing 20 in

Landing sub at 1,200 m

Pilot Hole 14in 17 in

Hole 12in 14 in

Hole 8in

Conductor 36 in

Liner 9 5 8in97 8in

Pills 1.05 g/cm 3

Synthetic Mud1.201.25 g/cm 3

Sea Water andViscous Pills

Pump & Dump

1.051.35 g/cm 3

Synthetic Mud1.551.65 g/cm 3

Synthetic Mud

1.301.40 g/cm 3

Synthetic Mud1.451.52 g/cm 3

Liner 7 5 8in

Rotarytable=765 mTop well head 18 in=2.30 mTop housing 36 in=2.30 mLanding sub colled 20 in 16 in=1,250 m

TD=5,350 m

KOP 3,420 m

PLANNED

Dark zone = 2 m Jetting

BL

BL

Temp. seafloor=4.5 degC

Sea Water and Viscous Sea Water and Viscous

Final Well Geometry

A real-time drilling optimization program was key to the success of the Kabilil exploratory well due to uncertainties that

remained even after extensive upfront planning. In the 16-in. casing section, seismic-while-drilling data was used to acquire

depth-velocity information, calibrate the geomechanical and geological models and provide real-time surveillance to

adjust the model against the pre-drill model. In the 9 5/8-in. and 8 -in. open-hole sections, real-time LWD tools were used to

gather petrophysical information.

-

8/10/2019 201307 Drillingcontractor Pemex Deepwater Gom Subsalt Drilling

5/5

Innovating While Drilling

R E P R I N T E D F R O M T H E J U L Y / A U G U S T I S S U E O F D R I L L I N G C O N T R A C T O R

REAL-TIME VISION

Because the Kabilil well was an explor-

atory well, it was prudent to acquire LWD

data while drilling to reduce uncertain-

ties. The primary objective of the look-

ahead seismic-while-drilling service was

to reduce the depth uncertainties andidentify potential risk zones. Additionally,

LWD measurements were acquired for

calibrating the geomechanical and pore

pressure models.

For example, a real-time look-ahead-

of-the-bit check shot and vertical seismic

profile (VSP) of the interval between

1,500 meters and 2,200 meters (4,921 ft

to 7,218 ft) was deployed in the 16-in.

casing section where the fault plane had

been predicted. The VSP data below the

drill bit revealed homogeneous reflec-

tions rather than the strong amplitudethat had been expected for salt pres-

ence.

The seismic-while-drilling information

made it possible to precisely map the bit

position and identify the location of the

fault plane to set the 16-in. casing just

below that point. When drilling resumed,

the location of the fault plane was used

to determine when to stop drilling for the

16-in. casing. The system also conducted

a salt proximity survey in the 13 5/8-in.

section, determining that the well was

actually closer than expected to the salt

dome, a minimum distance of approxi-

mately 163 meters (535 ft).

Real-time LWD tools, used for the ini-

tial formation evaluation and pore pres-

sure predictions, were deployed in the

9 5/8-in. and 8 -in. open-hole sections

to provide petrophysical informationto determine whether further data was

needed for each target zone.

The logging suite was enhanced with

sonic to measure formation velocity for

correlating seismic activity with the

seismic model. The sonic log calculated

the pore pressure profile, allowing geo-

mechanical engineers to calibrate the

mechanical earth model and devise a

wellbore stability model that included a

reliable collapse pressure, complement-

ing the 3D modeling work performed in

the pre-drill planning stage.The PEMEX Kabilil-1 exploratory well

demonstrated how optimum drilling per-

formance can be achieved in a challeng-

ing deepwater subsalt well through the

integration of effective pre-drill modeling,

risk management, real-time monitoring

and a workflow process built on strong

communication and teamwork.

Although the well ultimately did not

prove to not to be a viable producer

and has since been abandoned, the suc-

cessfully executed drilling program pro-

vided important lessons for the operator.

PEMEX has since drilled 18 deepwater

wells and four ultra-deepwater wells at

water depths approaching 3,000 meters

(9,843 ft) in the same basin.

VISAGE is a mark of Schlumberger.

References

Vallejo, V.G., Solis, E., Olivares, A., Aguilera,L.E.,

Torres, M.E. and Gonzalez, L. Drilling a

Deep-Water Well in a Subsalt Structure in

Mexico, Pennwell, Deep Offshore Technology

International. ID number 145. Conference held

in Perth, Australia 2729 November 2012.

Aguilera, L.E., Jimenez, G., Lougon, A., Macias,

J., Martinez, M. and Bracho, L., Geomechanics

and Pore Pressure Considerations for

Successful Deep-water Exploration Drillingpaper SPE WVS 040

South American Oil and Gas Congress, orga-

nized by the SPE Western Venezuela Section,

held in Maracaibo, Venezuela, 1821 October

2011.

Sanchez, A, Mora, A. Aguilera and L.E,

Gaitn, R., Minimizing Drilling Risks for

Exploration well in deepwater using Seismic

While Drilling Technology, in Rio Oil &

Gas Expo and Conference 2010, held in Rio

de Janeiro, Brazil, 13-16 September 2010.

To mitigate challenges

identifed during the

pre-drill planning phase,

seismic-while-drilling was

used to acquire depth-

velocity information in

real time. A real-time

check shot and VSP wasacquired of the interval

between 1,500 meters

and 2,200 meters in the

16-in. casing section,

where a fault plane had

been predicted. Further,

a salt proximity survey

was conducted in the 13

58-in. casing section. Raypath

Salt Salt

Energy source

Salt

Receiver

Depth, m

Horizontal DistanceBetween Receiver and

Salt Flank, m

2175.7 196.4

2204.3 185.7

2232.9 176.0

2261.1 182.0

2289.4 184.0

2318.2 187.5

2347.0 183.4

2375.8 178.4

2404.4 175.8

2432.6 177.9

2460.9 172.72489.1 171.4

2517.2 167.7

2545.8 164.1

2573.0 163.0

2601.3 171.3

2629.6 179.8

2658.1 175.7

Look Ahead Survey 17 in 20 in Salt Proximity Survey 14 in 17 in

Drill bit @ 1,761 m

Drill bit @ 2,140 m

Salt

Fault

Lower Miocene

Corridor stack with

BPF 6-30Hz and using

just seven levels